Packaging Color Difference

In the field of packaging design, in order to enhance the added value of the product as much as possible and to attract the attention of consumers, it is necessary to accurately control the color quality of the packaging. In order to establish a brand image and improve product recognition, major manufacturers will make painstaking efforts in product packaging design, so that the packaging colors more closely match the characteristics of the product. However, although the packaging design color is perfect, if the color deviation of the packaging occurs in the actual production process, the effect will be greatly reduced.

At present, there are many kinds of packaging on the market. The raw materials and production processes used in production are also different. Here we take the common packaging printing color difference as an example to briefly analyze the main causes of packaging color difference:

1. Cause one: equipment conversion

The packaging design of the product is usually made through a computer or various electronic devices. Then the matching color is selected and the sample is submitted to a printing company for printing. Then there is the problem of color conversion and inconsistent color standards in this process.

Most of the commonly used computers and electronic display devices use RGB color mode. The printing machine uses CMYK color mode. When the device is converted, it will cause color difference problems in packaging and printing. High precision colorimeter can be used to avoid this problem. By using colorimeter, we can know the cloest color code matching the measured color. Multiple color charts are installed in the Linshang colorimeter App, such as Pantone color chart. You can select the color chart first, then three cloest color codes of the Pantone color will be matched. Then you can know the Pantone color code of the test sample, next time you want to use this color. You just need to tell others the Pantone color code. There is no need to worry about the color deviation when equipment changes.

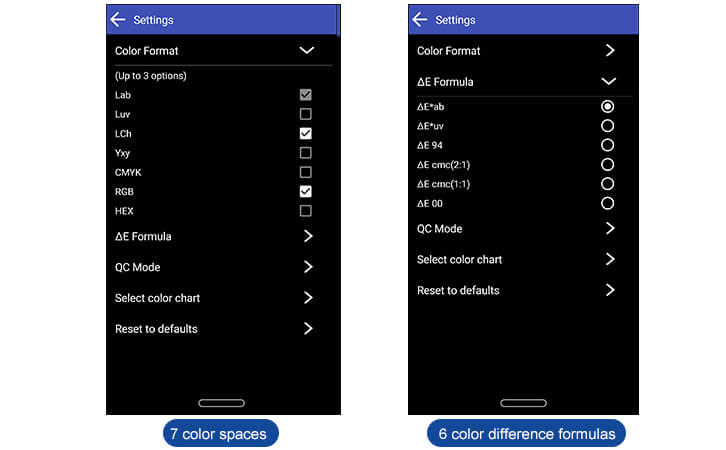

Six color difference formulas and seven color spaces can be selected, the specific selections can be seen below:

2. Cause two: inconsistent color evaluation standards

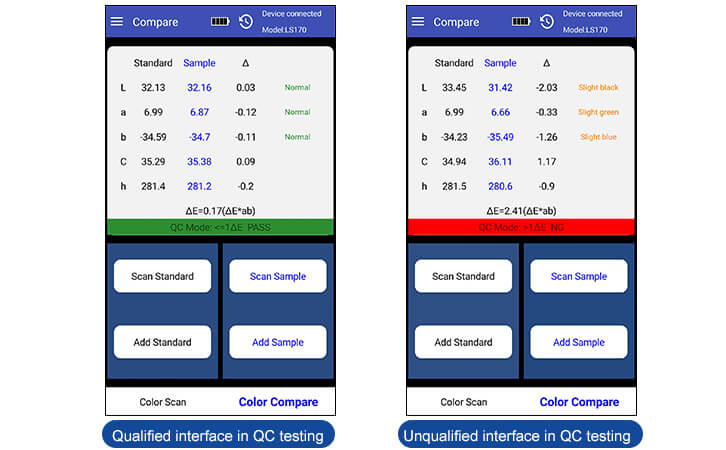

When the printing manufacturer prints out samples according to the packaging design color, it will repeatedly communicate with the customer to confirm whether the packaging printing color is consistent and the acceptable color deviation. However, due to the inconsistency of the color evaluation standards of both parties, the color deviation of the product during batch printing may also occur. For example, the printing factory performs color matching under the D50 light source. The customer requires color matching under the TL84 light source. Since the standard light source environment for evaluating colors is inconsistent, the final packaging color evaluation results will be different. By using the QC testing function of Linshang portable colorimeter, manufacturers can judge the whether the goods is qualified. We can set the value of the ΔE*ab (0-50 can be set), if the ΔE*ab exceeds the set value, the colorimeter will judge the goods as unqualified.

3. Cause three: printing process

In the process of batch printing, comprehensive factors such as ink quality, differences in ink formulations of different batches, problems of the printing machinery itself and manual operations of printing workers may all cause different batches of packaging printing and different parts of the same batch. It is impossible to completely avoid the problem of packaging and printing, but we can control the quality of the packaging and printing process through a professional colorimeter, so as to control the color difference of the package within a reasonable range and meet the requirements of the company for packaging color.

4. Portable colorimeter control the color quality

Packaging color difference is generally detected using a portable colorimeter. The portable colorimeter is an optical detection instrument that simulates the color viewing process of the human eye. According to the principle of CIE color space, the degree of difference in packaging color can be expressed numerically. The △E and △Lab values can accurately determine the color deviation of the packaging, further adjust the production process and control the color quality of the packaging.