LS215 Ultrasonic Thickness Gauge

Measurement from 1–320 mm with 0.01 mm display resolution

Nondestructive measurement of metal pipes, steel plates and plastics

Compatible with 4 interchangeable probes for broader applications

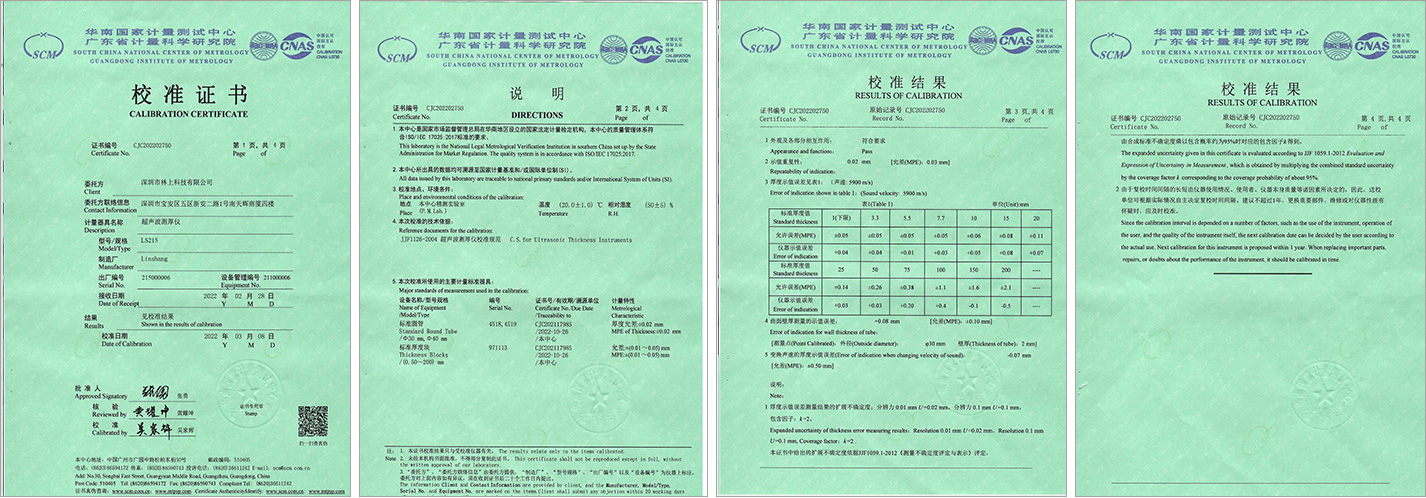

High accuracy, compliant with metrology verification requirements

999 data groups for secure data storage

LS215 ultrasonic thickness gauge adopts the pulse echo measurement principle to perform nondestructive testing on steel, aluminum, copper, plastics, ceramics, glass, and other sound-conductive materials. With a display resolution up to 0.01 mm, the LS215 meets the accuracy requirements verified by the national metrology institute. Four probes are available—standard, micro-diameter, coarse-crystal, and high-temperature—which can be freely selected based on application needs.

LS215 feature video

Application

Suitable for measuring the thickness of metal plates, steel parts, pipes, ceramics, plastics, glass and any other material that conducts ultrasonic waves.

Note: For accurate results, the rear surface of the test piece must be parallel or coaxial with the test surface. For curved samples, ensure the split surface of the probe is perpendicular to the curvature axis.

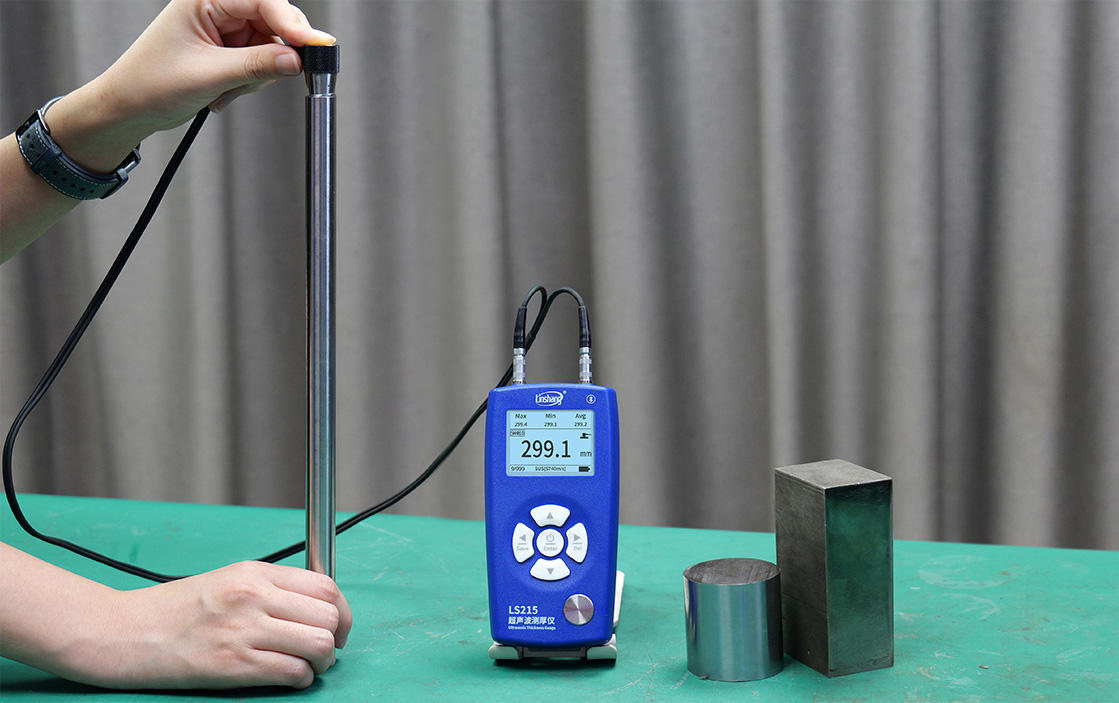

LS215 tests steel plate

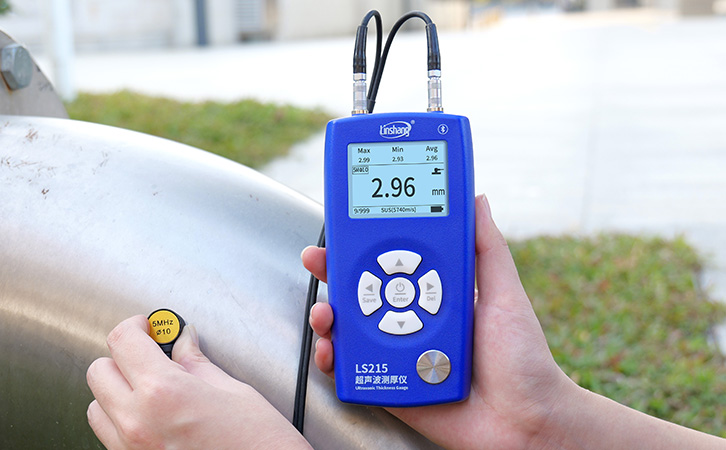

LS215 tests stainless steel pipe

LS215 tests plastic

LS215 tests glass

Parameters

1. Probe Parameters

| Probe | Standard Probe | Micro-diameter Probe | Coarse Crystal Probe | High Temperature Probe |

|---|---|---|---|---|

| Probe Model | 5MHZφ10 | 7MHZ PT-06 | 2MHZ ZT-12 | 5MHZ GT-12 |

| Application | Measure conventional workpieces | Measure curved surfaces and small workpieces |

Cast iron and some materials with large crystal particles |

Measure high temperature workpieces |

| Minimum measuring area | φ10mm | φ6mm | φ12mm | φ12mm |

| Probe size | φ18*26mm | φ15*25mm | φ18*28mm | φ43*48mm |

| Measuring Range (45#steel) |

1-320mm | 0.75-80mm | 3-200mm | 3-200mm |

| Accuracy (H is the standard value) |

H<10mm: ±0.05 H≥10mm: ±0.5%H |

H<10mm: ±0.05 H≥10mm: ±0.5%H |

H<10mm: ±0.1 H≥10mm: ±1%H |

H<10mm: ±0.05 H≥10mm: ±0.5%H |

| Exposure temperature | -10~60℃ | -10~60℃ | -10~60℃ | -10~500℃ |

| Pipe measurement lower limit(45# steel) |

φ20*3mm | φ20*2mm | φ30*4mm | φ30*4mm |

2. Main Unit Parameters

| Parameters | Values |

|---|---|

| Resolution | 1-100mm:0.01mm 100-320mm:0.1mm |

| Sound Velocity Range | 1000~19999 m/s |

| Display | 240 * 160 dot matrix LCD |

| Units | mm/inch |

| Power | 2pcs of 1.5V AA alkaline battery |

| Host Size | 142*72*28 mm |

| Weight | About 230g |

| Operation Temperature Range | -10~60℃,0~85%RH(No condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(No condensation) |

LS215 appearance dimensions

LS215 battery

Features

Wide Measurement Range

Measures materials from 1 to 320 mm in thickness, meeting a wide range of application needs.

Interchangeable probes for convenient measurement

Supports standard, micro-diameter, coarse crystal, and high temperature probes, with automatic probe identification.

High accuracy for metrology verification

Accuracy up to ±0.05 mm, fully capable of passing national metrology testing.

Large data storage capacity

Stores up to 999 measurement groups, reducing the risk of data loss.

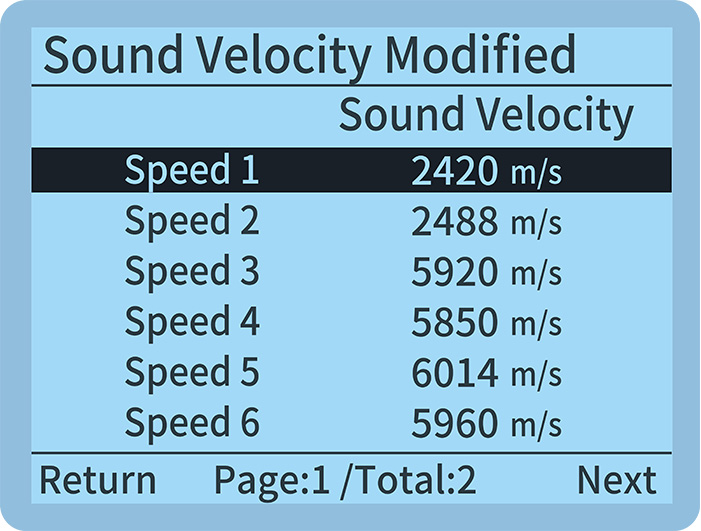

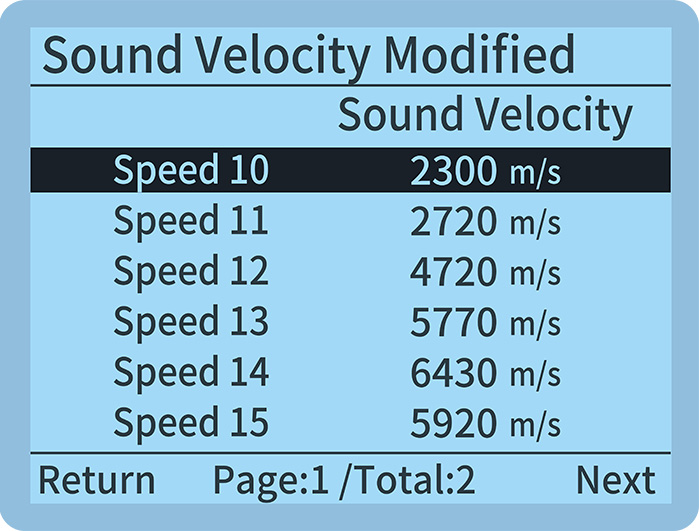

19 built-in sound velocities

Includes preset velocities for 19 common materials for quick setup and faster operation.

18 Customizable sound velocity settings

Save up to 18 additional sound velocities (9 Set by thickness + 9 Manual input), ideal for special materials.

LS215 known thickness setting sound velocity

LS215 manual sound velocity setting

With E-E measurement mode

The standard probe features a E-E measurement mode, which supports measuring base material thickness through coatings without paint removal.

Professional timing chip for precise measurement

Built-in a professional timing chip, offering excellent stability and measurement accuracy with 0.01 mm resolution

High-sensitivity dual crystal probe

Dual-crystal design improves signal response, reduces noise, and features a durable stainless-steel housing.

Automatic gain adjustment

Automatically adapts signal amplification based on material type and thickness to ensure accuracy across the full range.

Optional wrist strap

A wrist strap is available as an optional accessory, facilitating one-handed operation.

Mobile APP support

Connects to a mobile app via Bluetooth and supports storage of 50 data groups, with up to 999 readings per group, making it easy to save and share measurements anytime.

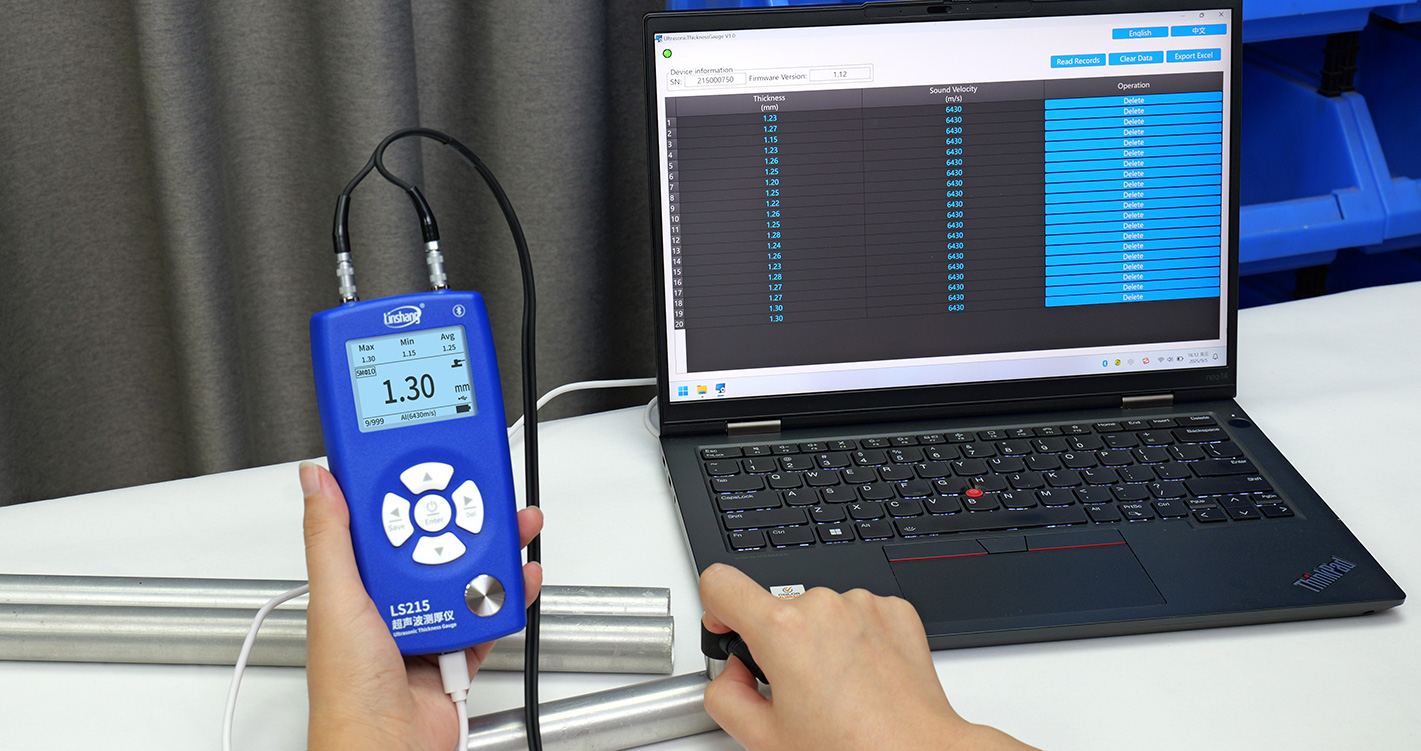

PC software connectivity

When connected to PC software, test data can be exported for storage and sharing.

Pass/NG thickness evaluation

In QC mode, upper and lower limits can be freely set, and the instrument automatically determines whether measurements are within tolerance.

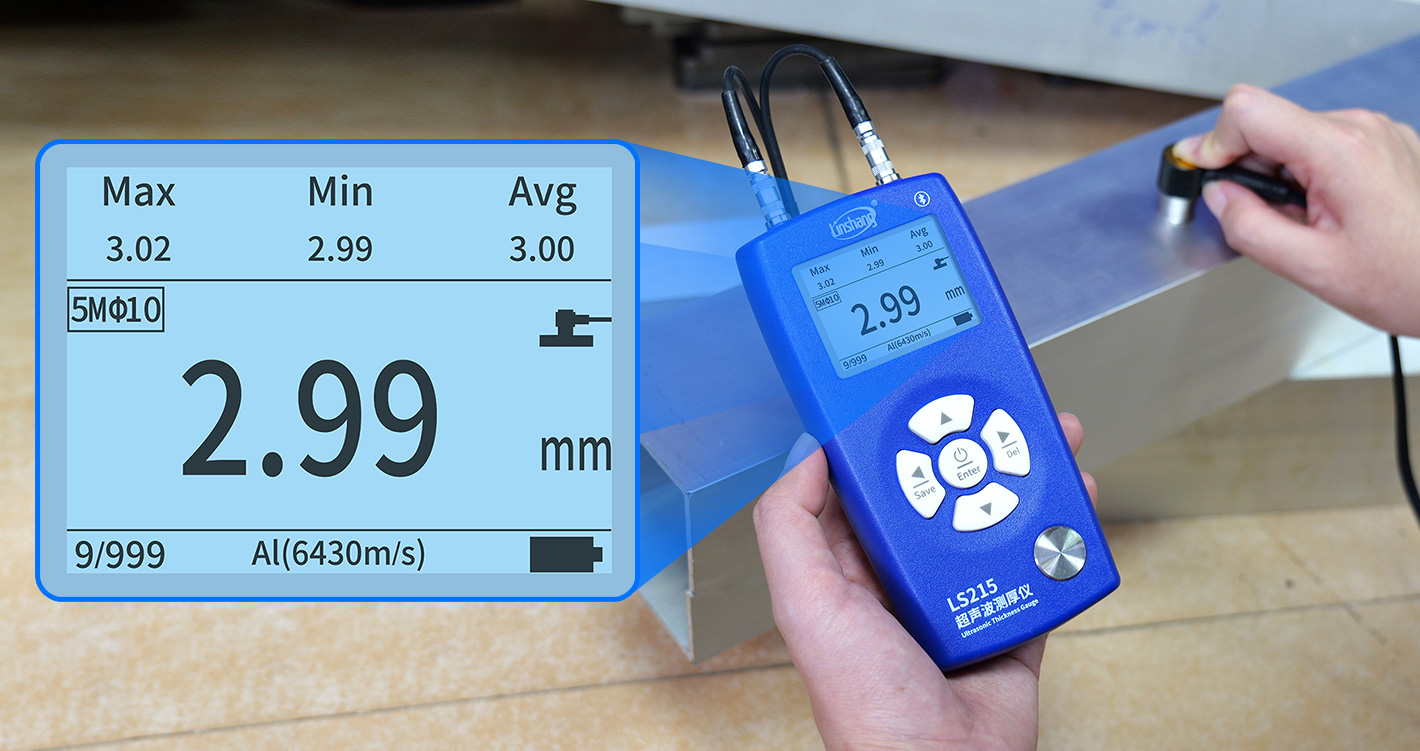

Smart data statistics

Automatically calculates maximum, minimum, and average values for material uniformity assessment.

Low power consumption enables continuous use

Protective silicone case included, drop & stain resistant

Supports Chinese and English, with two units of measurement

LCD with backlight to ensures clear readings

Qualifications and Standards

LS215 conforms to the following standards:

JJF 1126-2004 Calibration Specification for Ultrasonic Thickness Instruments

Software Download

The LS215 Ultrasonic Thickness Gauge is equipped with an APP that supports Android OS version 7.0 and higher. It can be installed through the following ways:

1)Scan the QR code on the instrument with your mobile browser, follow the instructions to download and install.

2)Click the link https://www.linshangtech.cn/a/253/ to install the APP.

3)Search for "UT and HL" (not case sensitive) in the Google Play to install the application.