LS216 Multilayer Ultrasonic Thickness Gauge

Multi-layer thickness measurement for various substrates

High-speed ADC data acquisition, resolution up to 1μm

Color touchscreen for easy operation

Wide range with built-in sound velocities for over 20 materials

Waveform display ensures accurate layer thickness readings

The ultrasonic thickness gauge is designed based on the pulse reflection ultrasonic measurement principle. It is professionally used to measure the thickness of the coating on the surface of non-metallic substrates such as plastic parts, wood, glass, and the thickness of the substrate itself. It can also measure the thickness of the coating on the surface of metal substrates and the thickness of the metal substrate itself.

LS216 Ultrasonic Thickness Gauge Five Major Features

Test paint coatings

Test plastics

Test glass

Test multi-layer materials

Test thick materials

Test pipes

Parameter

| Parameter Name | Parameter Value |

|---|---|

| Measuring Range | 13-5500μm (epoxy coating), 300-14800μm (45# steel) |

| Resolution | 1μm |

| Measuring Accuracy | ≤±(3%H+2μm), H is the standard value |

| Sound Velocity Range | 1000~9999m/s |

| Minimum Measuring Area | Φ6mm |

| Probe Frequency | 15MHZ |

| Display | 800 * 480 dot matrix IPS color screen |

| Unit | μm/mil |

| System Language | Simplified Chinese, English |

| Host Size | 141.7*91.1*22.6mm |

| Probe Size | Φ26*42.1mm |

| Weight | 475g |

| Operation Temperature Range | 0~40℃, 0~85%RH (no condensation) |

| Storage Temperature Range | -10~50℃,0~85%RH (no condensation) |

| Supply Voltage | Rechargeable lithium battery 3.7V@4000mAh |

| Charging Interface | USB(Type-C) |

| Supply Voltage | DC5V |

Features

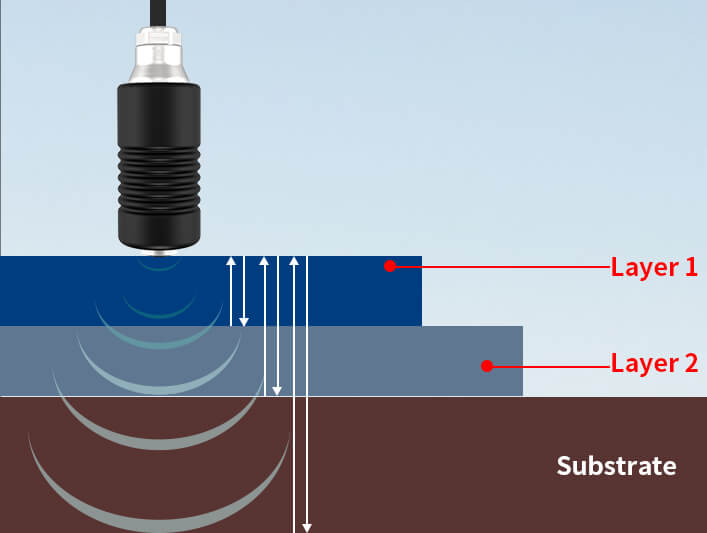

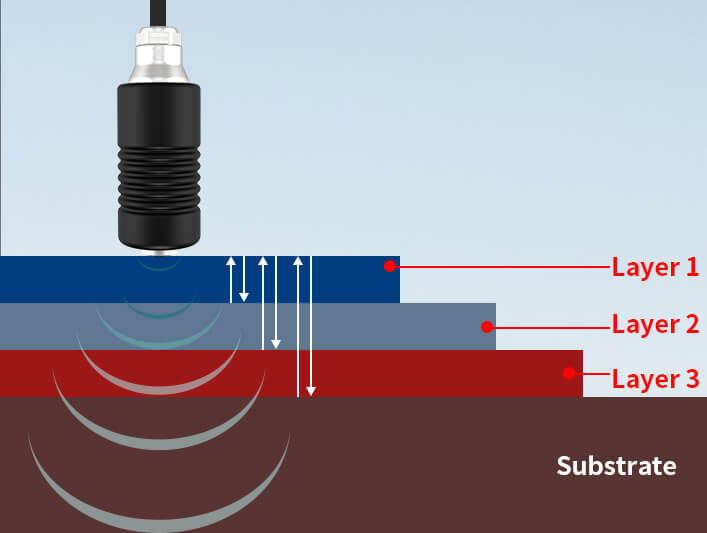

Supports Multi-layer Measurement

Measures coating thickness on nearly any substrate, supporting up to 3 coating layers or coating + substrate for complex inspections.

Micron-Level Accuracy, Industrial-Grade Precision

Equipped with a high-speed ADC for rapid data acquisition, the instrument offers a resolution of up to 1μm. It delivers outstanding accuracy for micron-level thickness measurements, making it ideal for demanding industrial inspection tasks.

High-Definition IPS Color Display

Industrial-grade IPS screen delivers clear, vibrant readings—easily viewable even under complex lighting conditions.

Ultra-Wide Measurement Range for Diverse Applications

Covers 13–5500 μm (epoxy coatings) and 300–14,800 μm (on 45# steel), meeting the needs of both ultra-thin and thick coatings across a variety of materials and complex industrial processes.

Real-Time Waveform Display for Visualized Measurement

Displays real-time measurement waveforms with a movable green cursor, allowing users to intuitively observe echo signals, analyze coating structures, confirm measurement boundaries, and enhance accuracy and reliability.

Automatic Gain switchable

Some materials are good conductors of sound and some are not. For the latter, the meter can switch the Gain freely which is to amplify the ultrasonic signal so that the emitted pulse is accurately captured by the transducer as it propagates, and obtains accurate data.

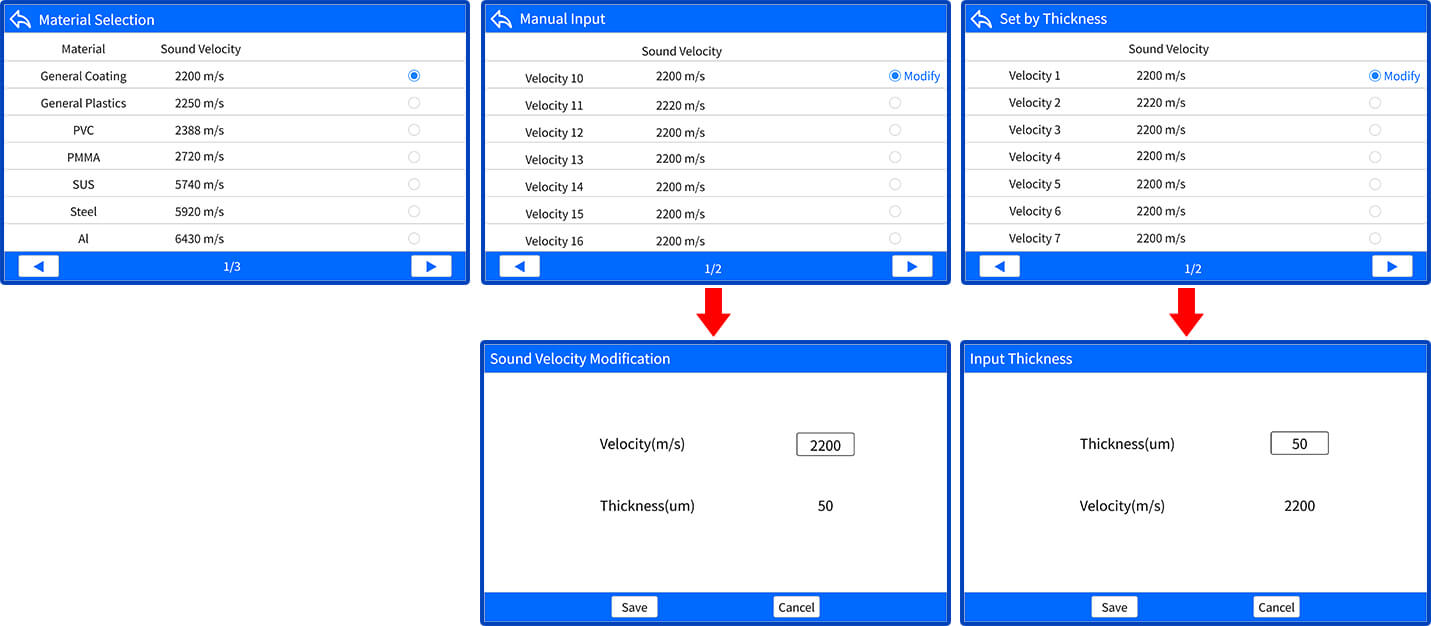

Three Sound Velocity Modes for Material Flexibility

Supports three velocity settings: select based on known material, calculate from known thickness, or manually input—adapting flexibly to different materials and measurement scenarios.

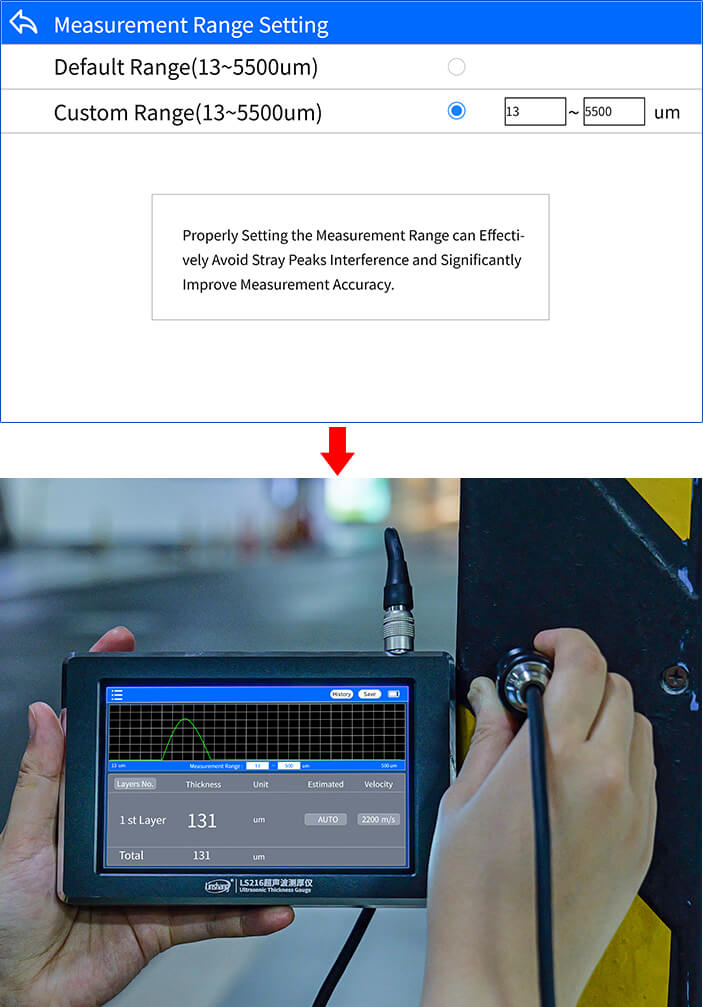

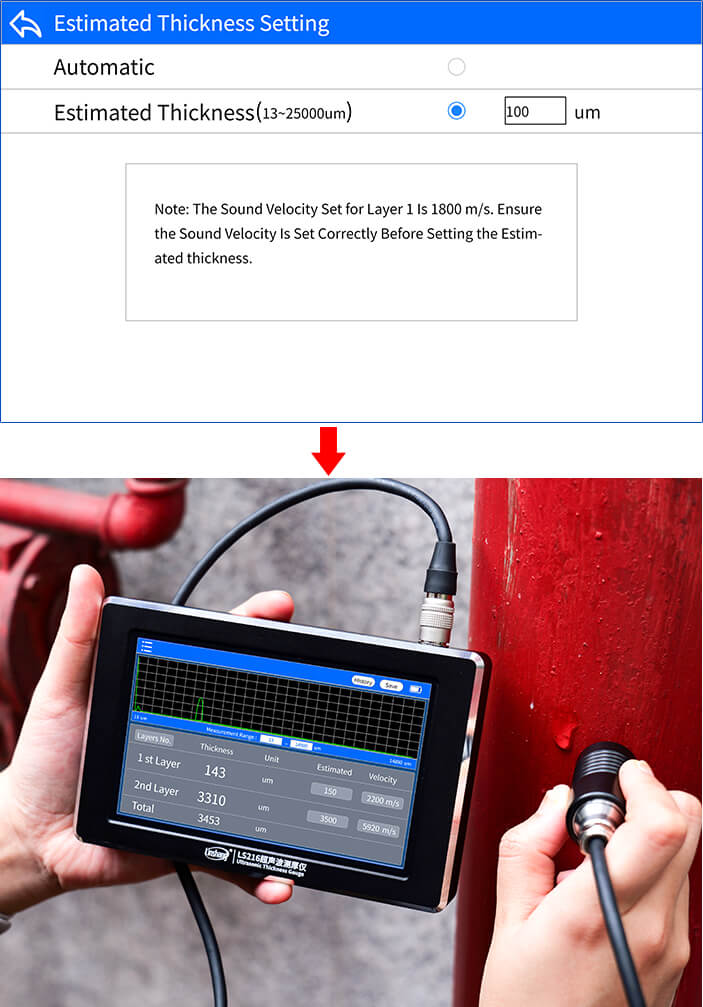

Range and Thickness Settings

The upper/lower range limits and estimated thickness settings effectively filter interference echoes, improving the accuracy of multi-layer measurements.

Measurement Range Setting

Estimated Thickness Setting

Φ6mm Minimum Measuring Area

Designed with a Φ6mm small measuring area, the instrument offers greater flexibility for measuring tiny or localized areas, making it ideal for inspecting fine structures and small-sized workpieces.

Supports Zero-Point Calibration

The probe can be zeroed before measurement, ensuring accurate coating thickness readings and maintaining high precision and stability in measurement data.

Continuous Measurement Mode

The instrument offers continuous measurement mode, which is beneficial to improve detection efficiency and enhance accuracy.

Powerful PC Software

With powerful PC software, measurement data can be exported with just one click. It makes long-term storage and team sharing effortless, ensuring smarter thickness data management.

Built-in Temperature Compensation

The ambient temperature compensation function ensures consistent long-term measurement data, eliminating the need for frequent recalibration.

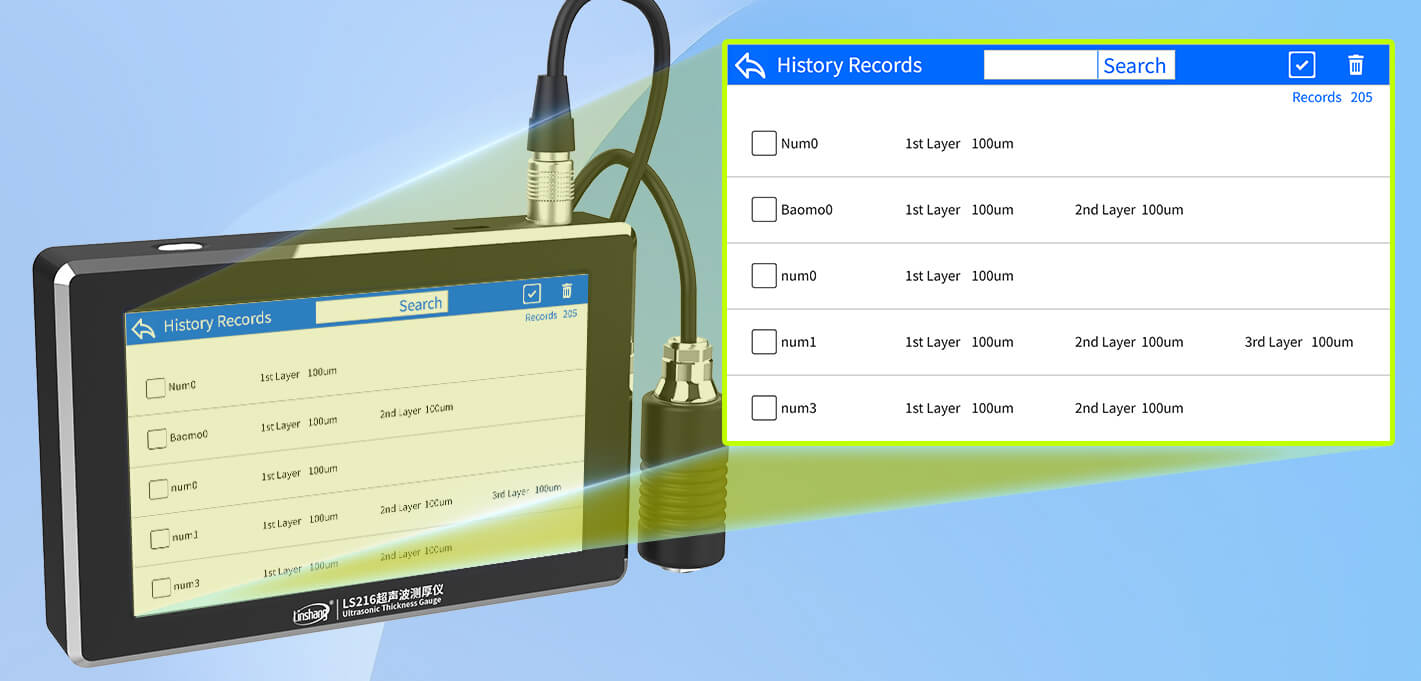

Ample Data Storage Capacity

With the ability to store up to 999 sets of measurement data, the instrument provides convenient access for later viewing and comparative analysis.

Precision Craftsmanship with Aviation Aluminum Body

Crafted with a precision CNC-machined aviation aluminum alloy shell, the instrument offers exceptional pressure and impact resistance.

Built-in Rechargeable Lithium Battery

Equipped with a 4000mAh large-capacity lithium battery and Type-C charging interface, the instrument offers quick charging and extended battery life to support high-intensity use in all conditions.

Switchable units of μm/mil

Selectable display languages

Intuitive and easy-to-use menu

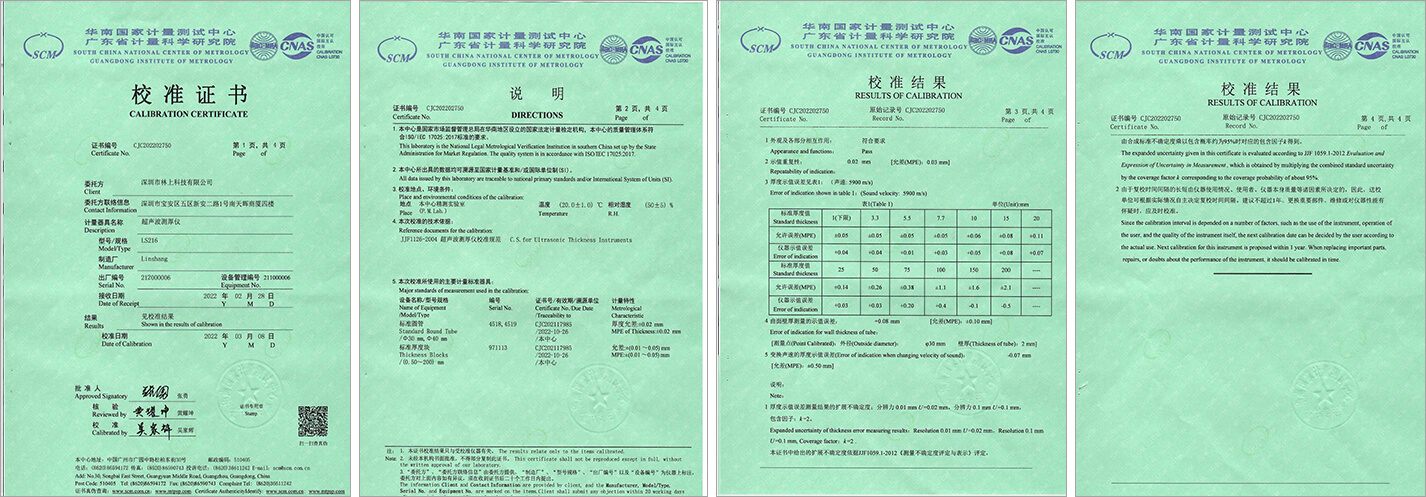

Qualifications and Standards

The product conforms to the standard:

GB/T 37361-2019 Determination of the film thickness—Ultrasonic thickness gauge method

JJF1126-2004 Calibration Specification for Ultrasonic Thickness Gauge.

Videos

LS216 Operation Video

PC Software video

Packing

| No. | Description | Quantity | Unit |

|---|---|---|---|

| 1 | Ultrasonic Thickness Gauge | 1 | pcs |

| 2 | Plastic Standard Test Piece | 1 | pcs |

| 3 | Charging Cable | 1 | pcs |

| 4 | User Manual | 1 | pcs |

| 5 | Calibration Report | 1 | pcs |

Your product information request

Please tell us a little about yourself and one of our salers will be in touch shortly!