LS251D Leeb Hardness Tester

Suitable for measuring iron, copper, steel and other metal materials

Using advanced digital probe technology, test accurately

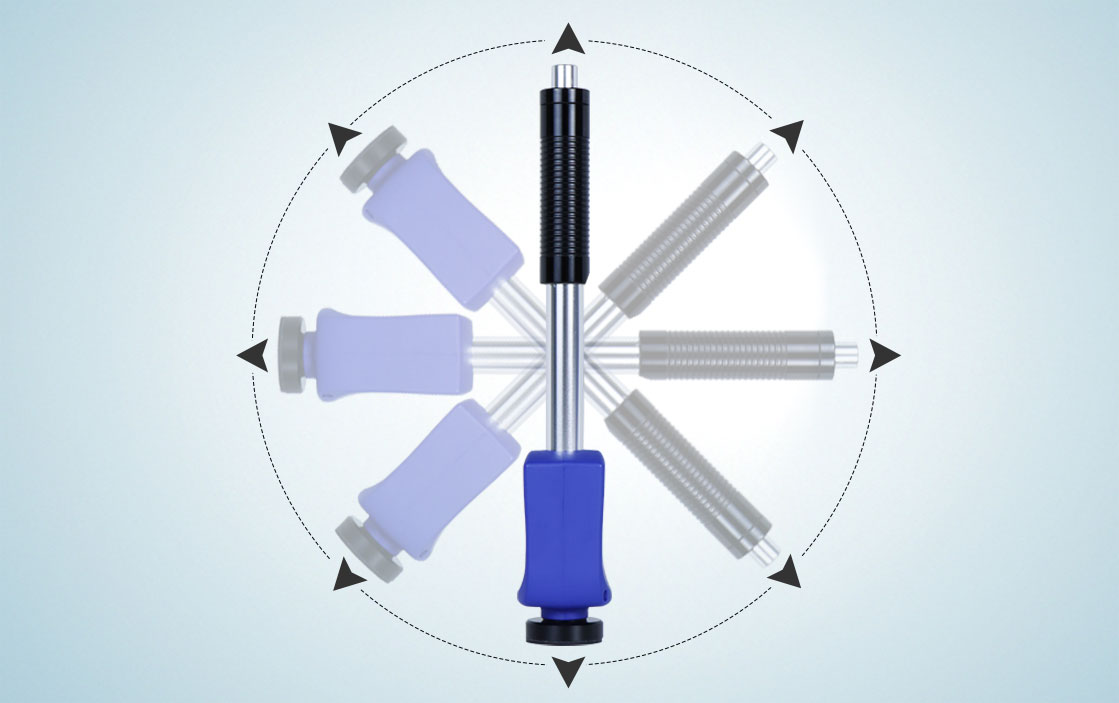

The probe has a built-in direction sensor to automatically compensate the measurement errors in different impact directions

A variety of hardness scales switchable, eliminating the tedious manual check table

LS251D Leeb hardness tester four major advantages

The ability of a material to locally resist hard objects pressing into its surface is called hardness, which is an index to measure the softness and hardness of a material. Based on the principle of Leeb hardness measurement principle, LS251D Leeb Hardness Tester can detect the hardness of a variety of metal materials. It adopts advanced digital probe technology, and the digital signal processing is completed directly on the probe which means that the probe is not easy to be disturbed and provides excellent accuracy. The orientation sensors inside the probe will compensate the measurement errors in different impact directions automatically to ensure the accurate data. Providing a variety of hardness scales , such as Leeb scale (HL), Vickers scale (HV), Brinell scale (HB), Shore scale (HS), Rockwell scale (HRA/HRB/HRC), and they can make a mutual conversion to avoid cumbersome manual calculation. Besides the hardness, the instrument can measure the strength of the materials. The practical value of using LS251D Leeb Hardness Tester for hardness testing lies in its incomparable portable characteristics that bring users a perfect experience.

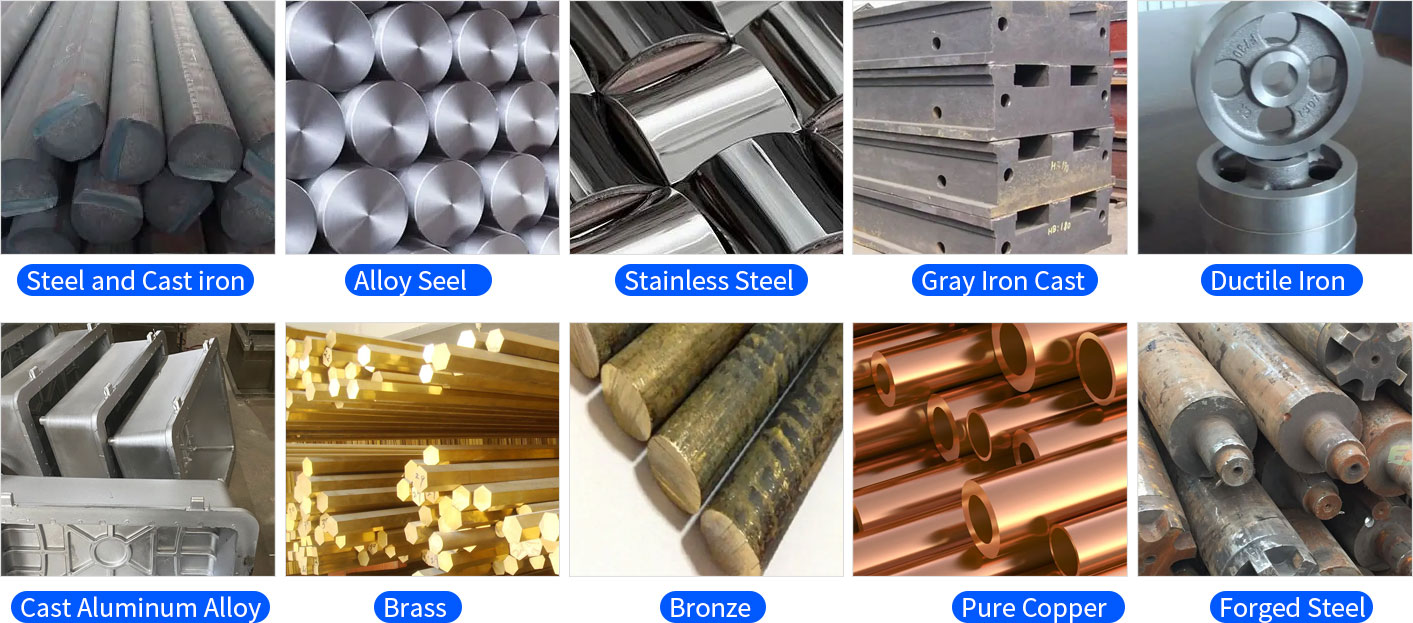

Applicable Materials

LS251D Leeb Hardness Tester is suitable for testing the hardness of materials such as steel, cast steel, alloy steel, stainless steel, gray cast iron, ductile iron, cast aluminum alloy, copper-zinc alloy, copper-tin alloy, pure copper and forged steel. The instrument can be widely used in machine tool guides, automotive chassis, heavy workpieces, mold cavities, bearings, pressure vessels and installed machinery or assembly parts and can help manufacturers to carry out product quality inspection and reasonable process analysis.

Parameters

| Probe | Impact device D |

|---|---|

| Hardness Scales | HL, HV, HB, HS, HRA, HRB, HRC |

| Measurement Range | HLD(170-960)/HV(83-976)/HB(30-651)/HRC(17.6-68.5) HS(26.4-99.5)/HRB(13.5-100)/HRA(60-85.8) |

| Resolution | 1HL |

| Accuracy | ±12 HL, ±6 HL typical |

| Repeatability | 6HL (factory standard) |

| Display | 240 * 16 dot matrix LCD |

| Power supply | 2 AA alkaline dry batteries |

| Host Size | 142*72*28 mm |

| Probe Size | 148*31*25 mm |

| Weight | 247g |

| Working Temperature Range | -10~50℃,0~85%RH(no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH(no condensation) |

Features

Using advanced digital probe technology

The tester uses advanced digital probe technology, and the digital signal processing is done directly on the probe, which is not easy to interfere with and provides excellent test accuracy

Direction sensor inside the probe will compensate the measurement errors in different impact directions automatically

The instrument can measure at any angles. Featuring a built-in direction sensor, the probe can automatically compensate the measurement errors in different impact directions. Multi-angle measurement is easy

Providing various hardness scales to switch, no more tedious manual check table

LS251D hardness tester provides a variety of hardness scales, which can be converted between Leeb (HL), Vickers (HV), Brinell (HB), Shore (HS) and Rockwell (HRA/HRB/HRC) eliminating the cumbersome steps of manual table lookup. Besides, it can not only test hardness but also the strength of materials enlarging the functions

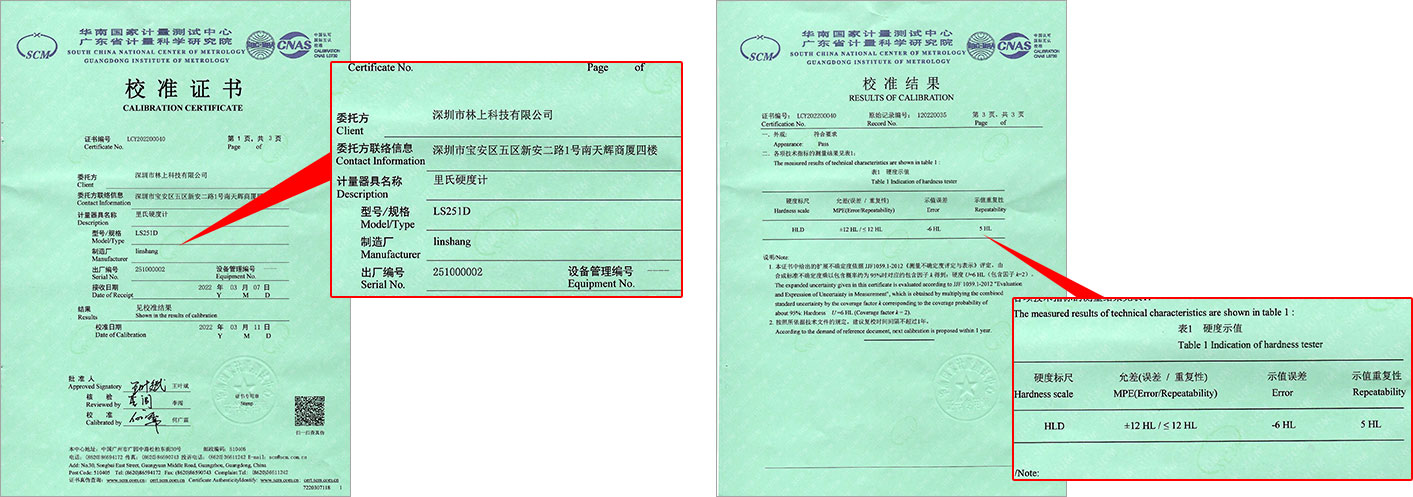

High-precision, ensuring that it can pass the inspection of the Chinese authoritative metrology institute

The measuring accuracy of LS251D can reach ± 6HL ensuring that it can pass the inspectionof the Chinese national authoritative metrology institute

QC inspection

The tester can set the upper ad lower limits and judge whether the hardness of the materials is qualified which is convienent for batch inspection

Statistics function

The tester can automatically count the maximum value, minimum value, and average value of the lastest 9 measured values

Providing Calibration

Users can calibrate the standard parts to eliminate the error

LCD screen, high brightness and easy for reading in dark environment

Low power consumption, and two AA alkaline batteries, which can work continuously for more than 100 hours

Equipped with standard Leeb hardness standard test block, the user can save the cost of subsequent test block consumables

Qualifications and Standards

LS251D Leeb Hardness Tester conforms to the following standards:

GB/T 17394.1 Metallic materials-Leeb hardness test-Part 1: Test method

GB/T 17394.2 Metallic materials-Leeb hardness test-Part 2: Verification and calibration of hardness tester

GB/T 17394.4 Metallic materials-Leeb hardness test-Part 4: Tables of hardness values conversion

JB/T 9378-2001 Industry standard of Leeb hardness tester

JJG 747-1999 Verification regulation of Leeb hardness tester

Videos

LS251D feature video

Leeb hardness tester can achieve 360° all-round measurement

Leeb hardness tester repeatability demonstration

How to calibrate Linshang Leeb hardness tester

Small mass workpiece coupling demonstration

Leeb hardness tester selection

The differences between different brands of Leeb hardness testers

Packing

| No. | Product Name | Quantity | Unit |

|---|---|---|---|

| 1 | Leeb Hardness Tester | 1 | Set |

| 2 | Standard Leeb hardness block | 1 | pcs |

| 3 | Nylon Brush | 1 | pcs |

| 4 | Small support ring | 1 | pcs |

| 5 | User Manual | 1 | pcs |

| 6 | Calibration Report | 1 | pcs |

| 7 | Certificate / Warranty card | 1 | pcs |

| 8 | Plastic Case | 1 | pcs |

FAQ

-

What is the thinnest thickness a durometer can measure and what is the thinnest thickness after coupling?

Leeb hardness tester is only suitable for large and heavy workpieces, small and thin parts must be coupled to a solid support for testing; D-type impact device is measured by the minimum mass of 5kg, the minimum thickness of 25mm, if the weight or thickness does not meet the requirements, must be coupled to a solid support for testing, coupled to the minimum thickness of the measured object is 3mm.

Your product information request

Please let us know your requirements and we will be in contact with you shortly!