LS256 Ultrasonic Hardness Tester

Integrated design + Two probes

Portable size, easy to carry

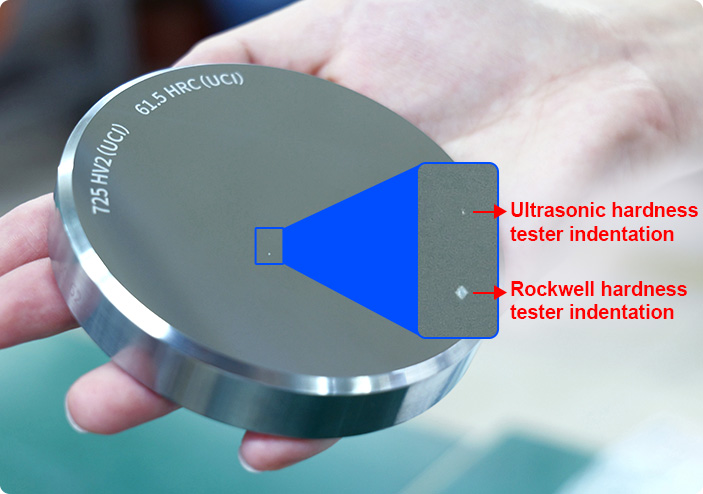

Small indentation, non-destructive measurement

Easy operation for measuring flat, small, or irregular parts

High precision, good repeatability

Ultrasonic hardness tester uses the ultrasonic contact impedance method to measure various metal materials. With minimal surface damage, it is ideal for testing metal coatings, plating, and hardened layers. It supports multiple hardness scales, including HL, HV, HB, HS, HRA, HRB, and HRC.

LS256 Featured Videos

Product application

LS256 Cylinder Liner Test

LS256 Flange Test

LS256 Fastener Test

LS256 Steel Plate Test

LS256 Wheel Hub Test

LS256 Surface Hardened Layer Test

LS256 Gear Test

LS256 Cutting Disc Test

Parameters

| Parameter Name | Parameter Value |

|---|---|

| Hardness Scales | HV、HRC、HRB、HRA、HS、HL、HB |

| Measurement Range | HV(50-1700), HL(170-960), HRC(20-70), HRB(13-100), HRA(60-85.8), HS(26.4-99.5), HB(30-651), HRE(20-70), HRF(60-100) |

| Resolution | 1HV, 0.1HRC |

| Accuracy | ±4%H+10HV,±2.5HRC (Probe fixture stand test, H as the standard value) |

| Repeatability | 3%H+8HV,2HRC (Probe fixture stand test, H as the standard value) |

| Test Force | 20N |

| Display | 240 * 240 dot matrix IPS |

| Power Supply | Rechargeable lithium battery 3.7V@1000mAh, full charge for over 5000 continuous measurements |

| Charging Port | USB(Type-C) |

| Size | 185*43*45 mm |

| Weight | 245 g |

| Working Temperature Range | -10~50℃,0~85%RH (no condensation) |

| Storage Temperature Range | -10~60℃,0~85%RH (no condensation) |

| Supply Voltage | DC5V |

| Operating Current | 60mA |

Features

Minimal Indentation for Non-Destructive Testing

Utilizing the ultrasonic contact impedance (UCI) method, the test leaves only tiny indentations, preserving the surface of precision or finished parts while delivering accurate hardness measurements.

Measurable Ultra-Thin Materials

The instrument can also perform accurate and non-destructive measurements on ultra-thin workpieces (if the sample does not meet the minimum mass of 300g and a minimum thickness of 5mm, grease can be used to couple the sample to a sturdy support for testing).

More Accurate Testing with a Hand Pressure Test Stand

A dedicated hand pressure test stand is available for users to choose from, making measurements more convenient and offering better accuracy and repeatability.

Simple Operation with Rapid Measurement

No complex settings required — just power on and test. Results are displayed in 1 second, ideal for batch inspections and fast-paced quality control.

Two Probes for Versatile Applications

Equipped with dual probes, the instrument adapts flexibly to a variety of hardness testing needs. Whether testing flat surfaces, small components, or irregularly shaped parts, it ensures accurate and reliable measurements.

Built-in Multiple Metal Materials

The instrument offers a selection of built-in metal materials to meet diverse measurement needs.

High Accuracy with Excellent Repeatability

A stable base ensures consistent probe positioning, delivering reliable results with high accuracy and repeatability.

Multiple Hardness Scales with One-Touch Switching

Built-in HV, HRC, HRB, HB, and other common hardness scales. Easily switch scales with a single button—no manual conversions needed.

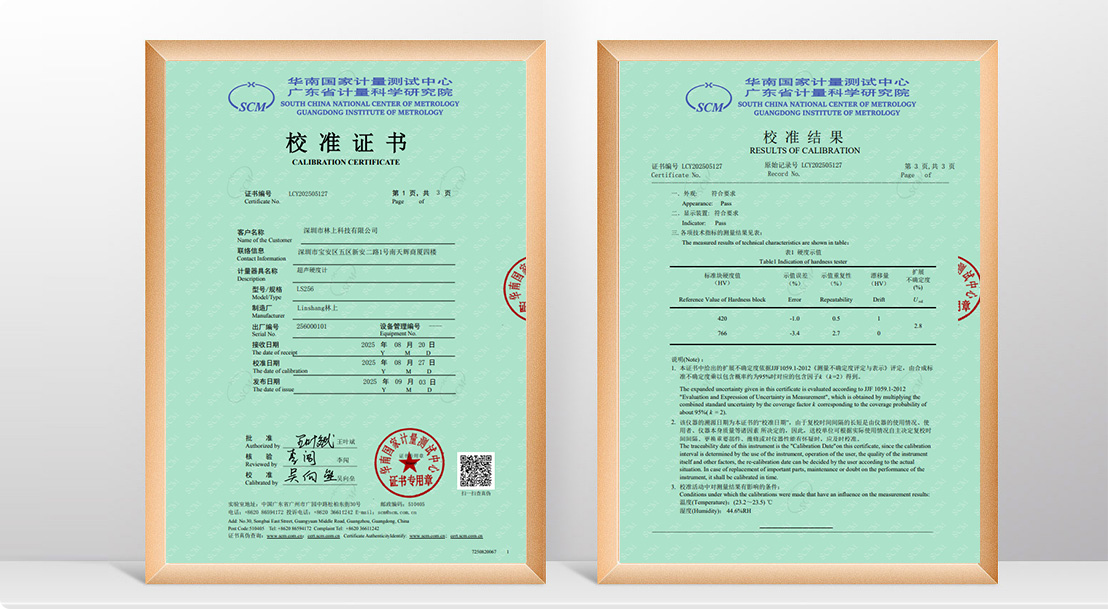

User Calibration Supported

Supports calibration with standard hardness blocks to reduce system errors and ensure accurate measurements.

Bluetooth Connectivity with Mobile App

Connects to a mobile app via Bluetooth for multi-set data storage, viewing, and sharing.

Integrated Design for Easy Portability

The instrument features an all-in-one structure that is compact and lightweight. It can be easily operated with one hand, making it ideal for fast and efficient on-site hardness testing.

Built-in Data Storage

Stores up to 9 sets of measurement data for convenient review and comparison anytime.

Ergonomic Design for Comfortable Handling

Ergonomically shaped for a secure, comfortable grip and smooth operation—ideal for extended use without fatigue.

Ultra-low power consumption

Equipped with standard hardness block

High-definition LCD display

Qualifications and Standards

Standards for the product:

GB/T 34205-2017 Metallic materials-Hardness testing-Ultrasonic contact impedance method

GB/T 33362-2016 Metallic materials-Conversion of hardness values

JJF 1436-2013 Calibration Specification of Ultrasonic Hardness Testers

Packing

| No. | Product Name | Quantity | Unit |

| 1 | Ultrasonic Hardness Tester | 1 | Set |

| 2 | USB Data Cable | 1 | pcs |

| 3 | Standard Hardness Block | 1 | pcs |

| 4 | User Manual | 1 | pcs |

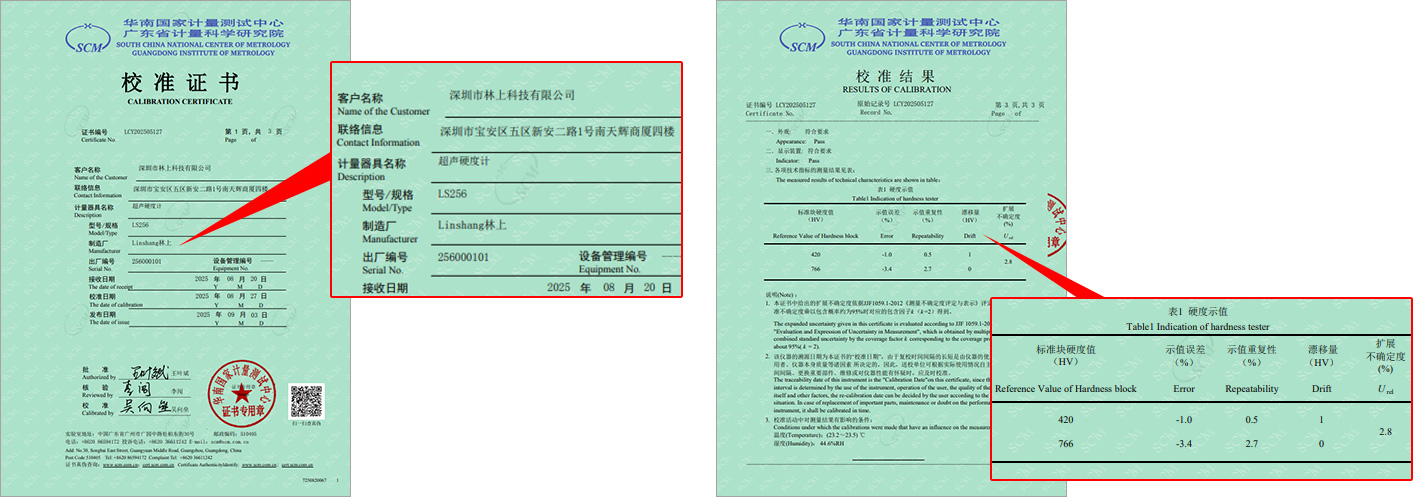

| 5 | Calibration Report | 1 | pcs |