LS225+N1500 Ultra-thin Coating thickness Tester

Test ultra-thin coating thickness below 10μm

Eddy current measuring principle

Measure the anodic oxide layer thickness on aluminum

Measuring range: 0-1500μm

LS225+N1500 is a split type plating thickness tester, which consists of the host and the digital probe N1500. It adopts the eddy current induction principle and has ultra-high measurement accuracy and repeatability which is especially suitable for measuring ultra-thin coatings and various small-sized work pieces and special-shaped materials.

Application

The LS225+N1500 plating thickness tester can be used in production inspection, construction acceptance as well as sales and exhibition sites. It can quickly and non-destructively measure the thickness of non-conductive coating on non-magnetic metal substrates. This plating thickness measurement device can be used in industries such as aviation, building materials, machinery, chemicals, engineering and instrumentation, etc.

LS225+N1500 Plating Thickness Gauge tests with fixture

LS225+N1500 Plating Thickness Gauge tests aluminum window sill

LS225+N1500 Plating Thickness Gauge tests ultra-thin coatings

LS225+N1500 Plating Thickness Gauge tests cell phone case

Parameter

LS225 Plating thickness tester host parameters

| Parameter | Value |

|---|---|

| Display | 240×160 dot matrix LCD |

| Power supply | 4pcs of 1.5V AAA alkaline battery |

| Operation temperaturerange | 0℃-50℃ |

| Storage temperaturerange | -20℃-60℃ |

| Host size | 148*76*26 mm (L*W*H) |

| Weight (include battery) | 194g |

N1500 probe parameters

| Parameter | Value |

|---|---|

| Measuring principle | Eddy current |

| Substrate | Non-ferromagnetic metal |

| Measuring range | 0.0-1500μm |

| Resolution | 0.1μm: 0μm - 99.9μm 1μm: 100μm - 999μm 0.01mm: 1.00mm – 1.50mm |

| Repeatability | ≤ ± (0.8%H+0.1μm) Test with fixture, H is the standard value |

| Accuracy | ≤±(2%H+0.3μm) after 5 points calibration, H is the standard value |

| Unit | μm / mil |

| Measuring interval | 0.8s |

| Minimum measuring area | Ø = 7mm |

| Minimum curvature | Convex:1.5mm / Concave:10mm |

| Minimum substrate thickness | 0.05mm |

| Calibration | Support zero reference adjustment and 1 to 5-points calibration |

| Probe size | 110*15 mm (Without connecting cable) |

| Probe weight | 81g |

Feature

Digital probe ensures the data stability

N1500 is a digital probe that suitable for measuring the coating thickness and the digital signal is processed on the probe, which is not easy to be interfered by the external environment, ensuring good data repeatability

Ultra-thin anodized coatings can be measured

Using digital oscillation technology and high-speed ADC acquisition, the plating thickness measuring instrument can measure ultra-thin coatings below 10μm and ensure accurate and stable data

Continuous measurement support

LS225+F500 coating thickness gauge can continuously takes measurements which is ideal for analyzing large areas and gets one measurement result in 0.4 seconds

Optional fixture and clamp for stable measuring

Purchasing a dedicated test fixture can eliminate the error caused by human factors and the data repeatability can reach 0.1μm

Zero-adjustment and multi-point calibration support

Zero-adjustment and multi-point calibration to ensure more accurate data. LS225+N1500 coating thickness gauge is equipped with a special zero adjustment plate and standard film

Powerful data statistic function

With data statistics function, the plating thickness measuring instrument can automatically count the maximum, minimum, average and the standard deviation of the latest 9 sets of data

Hard probe

The use of high hardness probe and increased durability design can ensure that the instrument has a long service life

Large measuring range

units switchable

Selectable display languages

Auto-off time within 1-9 minutes

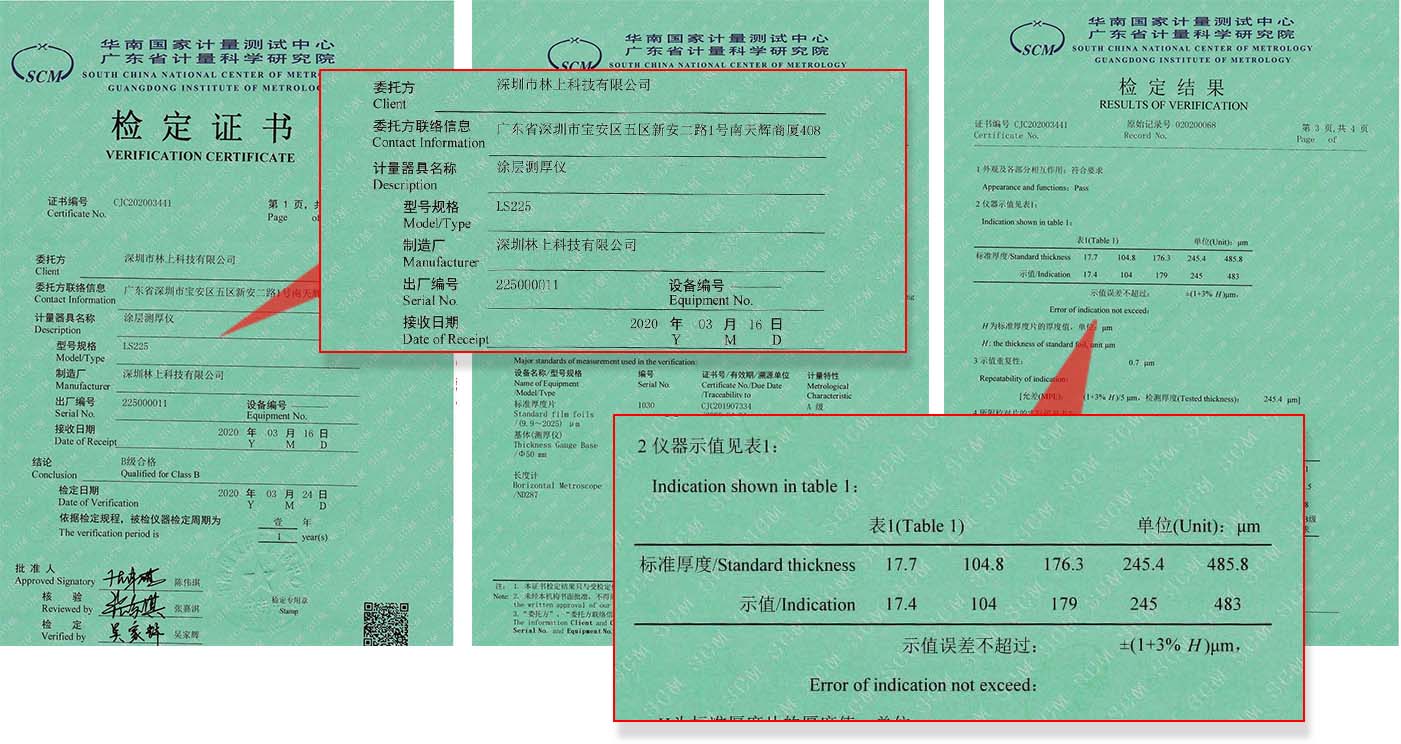

Qualifications and Standards

LS225+N1500 plating thickness gauge conforms to the following standards:

GB/T 4957-2003 Non-conductive coatings on non-magnetic basis metals-Measurement of coating thickness-Eddy current

DIN EN ISO 2808 Paints and Varnishes-Determination of Film Thickness

JJG-818-2005 Verification Regulation of Magnetic and Eddy Current Measuring Instrument for Coating Thickness

Videos

The introduction of LS225 with N1500 plating thickness gauge

How to choose the measurement mode of LS225 coating thickness gauge?

Coating thickness gauge measures PCB board conformal paint thickness

Linshang coating thickness gauge measures ultra-thin anodized layer

Why is coating thickness gauge adjusted to complete a zero-adjustment on the uncoated workpiece

Coating thickness gauge matches with dedicated stable fixtures to measure different workpieces

Packing

| No. | Description | Quantity | Unit |

|---|---|---|---|

| 1 | LS225+N1500 Plating thickness tester | 1 | pcs |

| 2 | N1500 probe | 1 | pcs |

| 3 | NFe zero-adjustment plate | 1 | pcs |

| 4 | Standard films | 7 | pcs |

| 5 | User manual | 1 | pcs |

| 6 | Certificate / Warranty card | 1 | pcs |

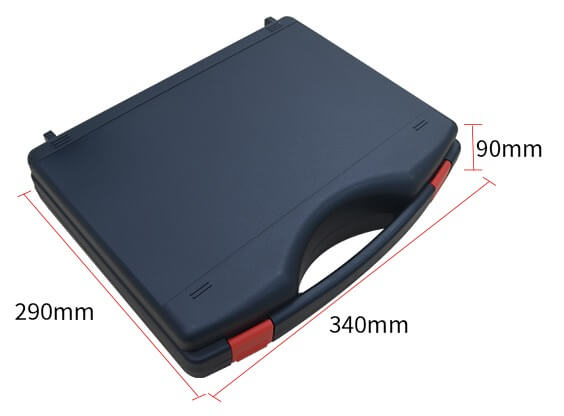

| 6 | Plastic engineering case | 1 | pcs |

Your product information request

Please let us know your requirements and we will be in contact with you shortly!

FAQ

-

1. The difference between LS225 and other coating thickness gauges

Compared with several other coating thickness gauges, LS225 has higher measurement accuracy and data repeatability. With a special test fixture, it can be used to accurately measure ultra-thin coatings below 10μm, small size and special-shaped workpieces. It supports zero adjustment and multi-point calibration. The measurement results can be more accurate after calibration through standard films or uncoated workpieces.

If you want to know more about the Linshang coating thickness gauge, Please click "Coating Thickness Gauge Selection and FAQ".