Reliable PCB Conformal Coating Thickness Gauge – Linshang LS226

Historically, conformal coatings were primarily used on circuit boards for mission-critical applications—such as aerospace—to protect devices from harsh environmental conditions like moisture, thermal shock, static electricity, vibration, and contamination. Today, with the rise of miniaturized and wearable electronics, the demand for the protection and reliability offered by conformal coatings has significantly increased. As a result, conformal coating thickness gauges have become essential tools for ensuring product quality. This article will introduce the purpose and necessity of conformal coatings, detail the standards and requirements, and explain how to use the LS226 Conformal Coating Thickness Gauge for precise measurements.

The Role of Conformal Coatings and the Need for Measurement

Conformal coatings, also known as protective coatings, are widely used on printed circuit boards (PCBs), electronic components, and automotive circuit boards. These coatings form a dense protective layer on surfaces to shield electronic devices from environmental damage. The main functions include:

Moisture and mold resistance: Prevents water vapor from corroding circuits and improves operational stability.

Salt spray corrosion protection: Extends the service life of equipment in coastal or highly corrosive environments.

Dust and contamination resistance: Effectively blocks dust and chemical pollutants.

However, if the coating is too thick, it may hinder heat dissipation; too thin, and it may fail to offer adequate protection. Therefore, accurately measuring coating thickness is a critical step in ensuring product quality—this is where conformal coating thickness gauges play a key role.

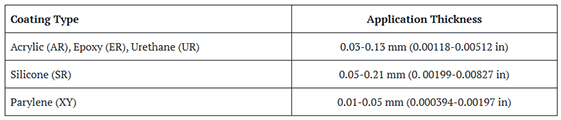

Standards and Thickness Requirements for Conformal Coatings

To ensure the performance of conformal coatings, industries and clients enforce strict coating thickness requirements. For example:

IPC Standards (e.g., IPC-A-610, IPC-HDBK-830): These are the most widely recognized standards in the electronics assembly industry. They typically specify a coating thickness range between 12.5μm and 200μm, depending on product class and application environment.

IEC Standards (e.g., IEC 61086): These define coating types, performance, and test methods, including thickness requirements.

Internal corporate/customer-specific standards: Many large corporations or niche industries (like automotive electronics) may impose more stringent or customized thickness specifications.

A highly accurate and repeatable conformal coating thickness gauge is crucial for ensuring compliance with these standards.

IPC-A-610

IPC-HDBK-830

How to Accurately Measure Conformal Coating Thickness Using LS226

The LS226 Coating Thickness Gauge is a portable instrument specifically designed to measure the coating thickness on flat materials like PCBs. It uses both eddy current and magnetic induction measurement principles and can automatically identify the substrate type, making operation simple and convenient.

Steps for measuring conformal coating thickness on a PCB with LS226:

Short-press the power button to turn on the device (avoid pressing on metal materials during power-up).

Zero calibration on an uncoated copper foil.

After zeroing, place the instrument probe steadily on the conformal coating surface of the PCB.

Read the measurement data directly from the display screen in real time (units: μm).

LS226 coating thickness gauge zeroing on copper foil

LS226 coating thickness gauge measuring the thickness of conformal coating

Key Advantages of the LS226 Conformal Coating Thickness Gauge

Linshang is committed to providing customers with high-quality, cost-effective instruments. The newly launched LS226 is developed to match the technical performance of advanced international products. While ensuring measurement precision and stability, it offers a more competitive price point, delivering outstanding value for customers.

Self-weight probe pressure ensures consistent force for each measurement—ideal for flat surfaces like PCBs.

Dual-display design allows easy data reading from both the front and the top.

Magnetic induction + eddy current measurement, with a wide range up to 2000μm, lightweight and portable for one-handed operation, suitable for fast, easy, and non-destructive coating thickness measurement on almost all metal substrates.

High precision of ±(2%H + 1μm), offering accuracy comparable to Germany’s Fischer MP0 series.

Multi-point calibration supported, with dedicated zeroing plate and calibration foils for high-accuracy measurements.

Two modes available: General Mode and QC Mode, adaptable to various application scenarios.

Built-in Bluetooth module enables mobile app connectivity for data storage, analysis, and report sharing.

Conformal coatings are indispensable for protecting electronic products, and a reliable thickness gauge is key to ensuring proper application and process control. With automatic substrate recognition, precise measurement capabilities, and accuracy comparable to international brands, the LS226 stands out as a trustworthy choice for conformal coating thickness testing.

- Digital Gloss Meter | How to Reduce the Surface Gloss of Materials?

- Why Do We Use Light Transmission Meter to Measure the Lens Transmittance?

- The Importance of Coating Film Thickness

- How Do You Choose A Paint Thickness Measurement Tool?

- Tips on Buying Paint Thickness Gauge

- Application of Paint Thickness Tester in Enamel Industry