Ultrasonic Thickness Gauge Comparison: Which One Should You Choose?

Compared to traditional destructive testing methods, ultrasonic thickness gauges have become the preferred tool in many industries due to their non-destructive measurement, high efficiency, and ease of use. However, with a wide range of models available on the global market, users often face a key question: How do you choose the right ultrasonic thickness gauge for your needs? This article offers a comprehensive comparison across four key dimensions—accuracy, functionality, cost-efficiency, and service support—to help you make an informed decision. We’ll also highlight a high-performance model that has proven to be a versatile and cost-effective choice for a wide range of applications.

Key Factors to Compare When Choosing an Ultrasonic Thickness Gauge

As ultrasonic measurement technology has advanced, numerous high-quality instruments have emerged, offering alternatives to traditional premium-brand devices. Here's how the different models compare across critical factors:

-

Measurement Accuracy

Leading global brands like GE and Olympus have long been known for their stable, high-precision instruments. However, recent technological progress has enabled newer brands to match or even exceed this performance. For instance, the LS216 Ultrasonic Thickness Gauge by Linshang Technology supports micron-level resolution and performs exceptionally well in most industrial testing scenarios.

-

Functional Features

Premium instruments are typically rich in features, but can be overly complex for general users. In contrast, newer models tend to offer more intuitive interfaces, localized language support, fast calibration, data export, and flexible upgrades—making them more accessible and user-friendly.

-

Cost Efficiency

High-end ultrasonic thickness gauges can be prohibitively expensive, often costing thousands of dollars. More cost-effective models, while maintaining high measurement accuracy, allow for lower overall investment, making them ideal for mass deployment or small to mid-sized operations.

-

Service and Support

While some high-end instruments may offer limited regional support or slower response times, many modern ultrasonic thickness gauge manufacturers—including Linshang—provide comprehensive global support through digital platforms. The LS216 Ultrasonic Thickness Gauge, for example, comes with: detailed English-language user manuals and training videos, prompt technical assistance via email or online support channels, and international shipping options and firmware designed to meet global standards. This ensures that users around the world can operate the instrument with confidence and receive timely assistance when needed—no matter where they are located.

Recommended Model: LS216 High Precision Ultrasonic Thickness Gauge

Among high-performance instruments available today, the LS216 from Linshang stands out as a reliable and user-friendly solution. Designed for professional thickness measurement, it balances advanced capabilities with practical usability.

Key Features of the LS216:

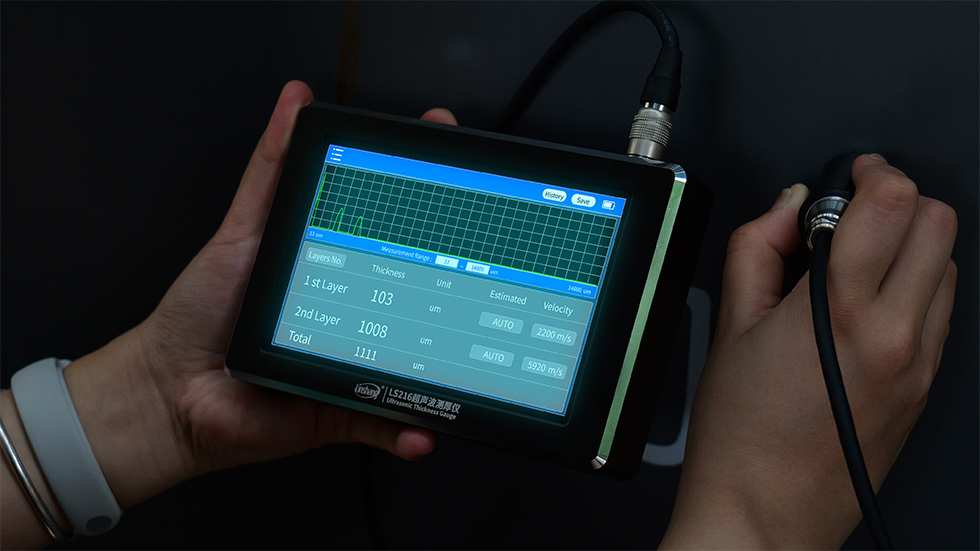

Multi-layer Thickness Measurement: Simultaneously displays the thickness of each layer and the total thickness—even for coatings on non-metal substrates.

1μm Resolution: Ensures precision in high-end applications such as electronics, plastics, and aerospace.

IPS Color Touchscreen: Delivers a clear visual interface and easy navigation, even in low-light environments.

Customizable Sound Velocity: Supports over 21 built-in materials and allows manual velocity settings for a wide range of materials including metals, plastics, ceramics, and rubber.

Automatic Gain Adjustment: Automatically optimizes signal amplification based on material type and thickness for consistent accuracy.

Real-Time Waveform Display: Features a movable blue cursor for detailed echo data analysis across different measurement points.

High Storage Capacity: Saves up to 999 groups of measurement data for later review and comparison.

Cost-Effective Alternative: Offers performance comparable to top-tier models, but at a more accessible price point.

Micron-level test accuracy

High-definition IPS color large screen

Real-time waveform display

As the global demand for precision and efficiency grows, more users are turning to high-performance, cost-effective ultrasonic thickness gauges. Instruments like the Linshang LS216 ultrasonic thickness gauge deliver the accuracy, reliability, and usability required across industries—without the high cost or complexity of traditional models. If you’re looking for a precise, stable, and easy-to-use thickness measurement solution, the LS216 is definitely worth a closer look. Contact us today to learn more about this device or explore custom solutions tailored to your application needs. Our team is ready to provide professional support and technical guidance.