What Is a Colorimeter / Spectrophotometer in Printing and Packaging?

In the printing industry, print spectrophotometers and colorimeters are essential tools to ensure that printed materials meet brand color standards. As printing technology continues to advance, customers’ expectations for precise and consistent colors are rising. Effective color control for printing gives printing companies a competitive edge and helps them attract high-quality clients. Conversely, inconsistent color can damage customer relationships and ultimately impact market share.

For printing manufacturers, a professional spectrophotometer for printing or a dedicated colorimeter in printing allows for highly accurate print color measurement, ensuring consistent color reproduction across all batches. Moreover, using a colorimeter or spectrophotometer can minimize material waste and significantly improve production efficiency.

What is a colorimeter/spectrophotometer in printing

Both colorimeters and print spectrophotometers are commonly used instruments for measuring color in the printing industry. Compared with a colorimeter, a spectrophotometer for printing is equipped with a spectral sensor capable of measuring light reflectance across the 400–700 nm wavelength range. It generates a complete visible spectrum reflectance curve, providing a more comprehensive analysis of color data.

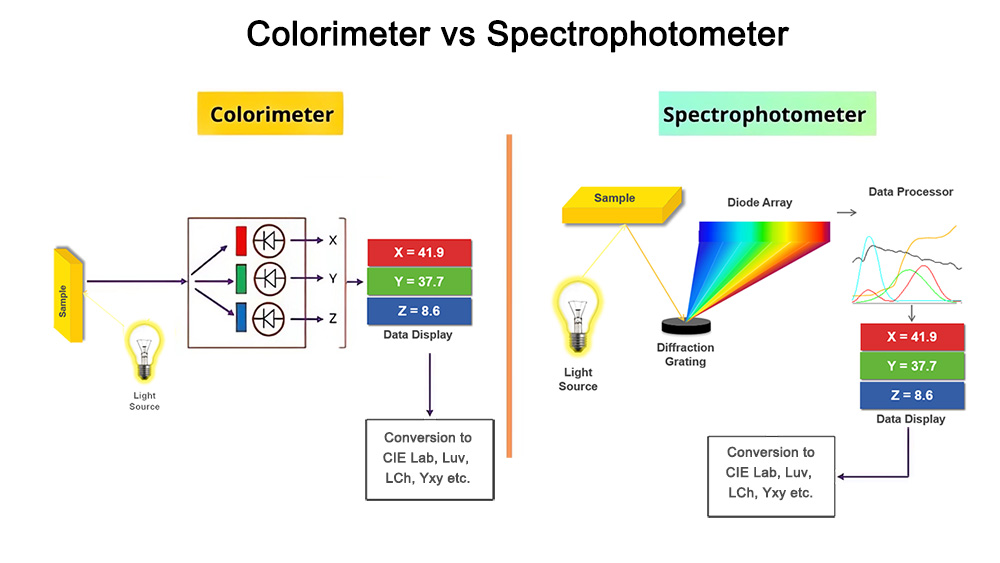

Working principle: colorimeter vs spectrophotometer

A colorimeter in printing uses a built-in full-spectrum LED white light that illuminates the sample. Certain wavelengths are absorbed while others are reflected back into the device. The reflected light passes through red, green, and blue filters to extract tristimulus values that closely match human visual perception, ultimately converting these readings into standardized digital color data.

A print spectrophotometer, on the other hand, measures the intensity of reflected light at 10 nm intervals across the visible spectrum. It then produces a spectral reflectance curve, from which the exact color of the sample can be calculated. By analyzing this reflectance curve, the spectrophotometer can detect phenomena such as metamerism (colors that look identical under one light source but different under another) — an advantage that a digital colorimeter cannot offer. This makes the spectrophotometer in printing an indispensable tool for advanced color control for printing.

Printing colorimeter/spectrophotometer

For the printing industry, Linshang has developed the LS372 print spectrophotometer, a model specifically designed for accurate print color measurement. It uses the industry-standard D50 light source, ensuring consistent illumination conditions throughout the entire printing workflow. As a portable handheld spectrophotometer, the LS372 features a 4mm small-aperture design optimized for measuring small color patches directly on the press control strip—ideal for on-site color checking beside the printing machine.

In publishing and commercial printing, such as books and magazines, both colorimeters and spectrophotometers in printing help ensure that printed materials faithfully reproduce the original design colors. This is particularly important for brands with custom-designed corporate colors, where precise color reproduction is essential for maintaining brand identity. In packaging printing plants, a spectrophotometer for printing or a colorimeter in printing is mainly used to check color consistency across production batches, especially for packaging boxes and color cartons. Effective color control for printing helps minimize batch-to-batch color variation and maintain uniformity in every printed product.

Why do we use a colorimeter/spectrophotometer in printing

Color plays a vital role in every aspect of visual communication, and precise color control for printing is the foundation of high-quality color management in the printing and packaging industries. Relying solely on human vision to evaluate color has significant limitations. Perception can vary greatly under different lighting conditions, and even the same observer may judge colors differently throughout the day. Visual fatigue is a key factor—our eyes are generally more sensitive to color differences in the morning than in the afternoon. This occurs because the cone cells in the retina, responsible for distinguishing color, become fatigued after extended use, reducing their sensitivity and making it difficult to differentiate between similar hues.

In contrast, using a colorimeter or print spectrophotometer provides objective, repeatable, and highly accurate results.

Advantages of a colorimeter/print spectrophotometer

In the printing industry, both colorimeters and print spectrophotometers typically use a 45/0 optical geometry, which simulates the way the human eye perceives color while eliminating external environmental interference. This ensures that each measurement is highly consistent and extremely accurate — an essential feature for professional print color measurement.

A colorimeter or spectrophotometer for printing converts color into objective, quantifiable Lab color data, making it easy to establish standardized color references. Whether for internal color management or for communication with clients, this data-driven approach is more efficient and accurate.

The Linshang print spectrophotometer features a large touchscreen interface that makes operation simple — color difference measurement can be completed with just two taps. It also provides color deviation indications to assist with color correction, helping operators easily master color control for digital printing.

In addition, the instrument includes multiple built-in electronic color charts and allows users to import custom factory color standards via computer software. This enables efficient spectrophotometer in printing applications, ensuring unified and standardized color management across all print jobs.

Furthermore, Linshang’s digital colorimeter and spectrophotometer support both Bluetooth and USB connectivity for linking with mobile apps and PC software. Users can perform real-time colorimeter measurement, print test reports, and share color data instantly—streamlining workflow and improving collaboration across the production process.

What does a colorimeter/spectrophotometer do in printing

Color consistency is crucial in the printing industry. If consumers notice obvious color variations in a book—whether between pages or copies—they are likely to question the overall quality of the product. Therefore, using a colorimeter or print spectrophotometer for precise print color measurement has become an essential part of maintaining print quality and achieving efficient production.

1. Paper and ink color testing

To ensure accurate and consistent print colors, it’s critical to first verify the color of paper and ink materials. A spectrophotometer for printing can be used to measure paper whiteness. Linshang LS372 print spectrophotometer includes multiple whiteness scales, such as WI-R457 and WI-Ganz, allowing fast and flexible paper whiteness measurement.

When testing ink color, the ink should first be evenly applied to standard paper (using an ink proofing machine, for example) to simulate actual printing conditions. Then, the LS372 can measure the color precisely. Conducting colorimeter measurement of raw materials helps prevent color discrepancies caused by variations in paper or ink, reducing waste and improving production efficiency.

2. Establishing standard print colors

Both colorimeters and spectrophotometers in printing can convert colors into objective, quantifiable Lab values, enabling the creation of consistent color standards. Once the standard color is confirmed, it can be saved directly in the device or entered as Lab data. During subsequent print runs, these standards allow quick and accurate color difference comparisons, ensuring stable and repeatable color control.

3. Automatic color difference calculation and deviation indication

Linshang LS372 spectrophotometer for printing can automatically calculate color difference values (ΔE) and provide color deviation indications whether a sample is more yellow, blue, or otherwise off-tone. This feature allows quick correction of ink formulations, improving repeatability, production efficiency, and overall print quality. Such color control for digital printing ensures every print meets the client’s color expectations.

4. Evaluating metamerism (color shift under different light sources)

One of the greatest advantages of a print spectrophotometer over a standard digital colorimeter is its ability to measure spectral reflectance curves and evaluate metamerism. Metamerism occurs when two colors appear identical under one light source but differ under another—a major concern for brands with strict color standards, such as printing Coca-Cola red.

Traditionally, metamerism testing required viewing samples under multiple light boxes. However, with a spectrophotometer in printing, this can be done quickly by analyzing the spectral reflectance data. This method ensures precise evaluation and helps printers meet the demanding color requirements of global brands.

5. Achieving digital and standardized color management

Linshang LS372 print spectrophotometer includes several built-in electronic color charts and allows importing custom factory color charts into the device. By communicating using Lab color data, both the printing company and its clients can avoid subjective misunderstandings about color perception. From design and proofing to final production, maintaining a unified color standard ensures consistent, high-quality print results that precisely match client requirements. With the LS372, printers can achieve fully digitalized, standardized color management across the entire printing workflow.

How to use colorimeter/spectrophotometer in printing

The primary purpose of using a colorimeter or print spectrophotometer is to detect the color difference between printed materials and the customer’s specified standard. Once the proofing color has been confirmed, a spectrophotometer for printing is essential to maintain color consistency throughout the entire production batch. Below is a practical example using Linshang LS372 print spectrophotometer, illustrating how to measure color accurately in printing applications.

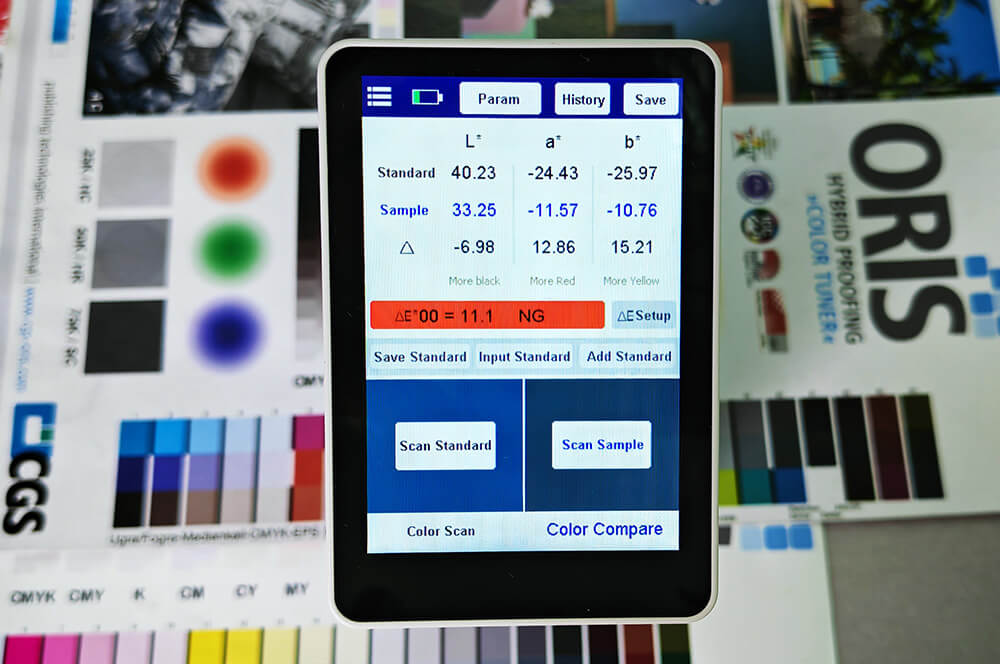

First, prepare the standard color samples—these can be customer-provided color charts (such as Pantone), proof sheets, or in-house color charts created by the printing factory. Then, set the acceptable color difference threshold (ΔE value). For example, you may define the pass threshold as ΔE*00 ≤ 2.0.

Next, place the LS372 print spectrophotometer steadily on the standard color sample and tap “Scan Standard.” Then, position the device on the actual printed sample—on the color patch or control strip—and tap “Scan Sample.”

The instrument will display the Lab color data for both the standard and the sample and automatically determine whether the color is within the color difference threshold. Additionally, the LS372 provides color deviation indications, helping operators adjust ink formulations accurately and efficiently.

Both colorimeters and spectrophotometers in printing play a vital role in maintaining precise color control for printing. They eliminate subjective color judgment errors, enhance productivity, and ensure consistent, stable print quality across every batch.

Related standards for printing color measurement

ISO 12647: Graphic technology - Process control for the production of half-tone colour separations, proofs and production prints

ISO 13655: Spectral measurement and colorimetric computation for graphic arts images

ISO 3664: Viewing conditions for graphic technology and photography

ISO 15339: Printing standards - Characterized reference printing conditions

G7: A Methodology for Gray Balance Calibration of Printing Systems

GRACoL: General Requirements for Applications in Commercial Offset Lithography

GB/T 17934: Graphic technology-Process control for the production of half-tone colour separations, proof and production prints

General reference for print color difference control

ΔE*ab ≤ 1.0: Color difference is nearly imperceptible, suitable for scenarios requiring strict color control in printing.

ΔE*ab ≤ 2.0: Acceptable range for professional printing.

ΔE*ab ≤ 3.0: Acceptable range for general commercial printing.

How to choose a reliable colorimeter/print spectrophotometer manufacturer

For any printing company, a high-quality colorimeter or print spectrophotometer is essential for maintaining precise color consistency. Selecting the right instrument starts with choosing a trusted manufacturer. Below are several reputable brands in the color measurement industry, ranging from international leaders to high-value and cost-effective options.

Top International Color Measurement Brands

X-Rite

X-Rite is a global leader in the field of color measurement. Its devices are known for exceptional precision, stability, and worldwide recognition of measurement data. For printers seeking ultimate color accuracy and consistency — and who have a sufficient budget — the X-Rite eXact 2 Portable Spectrophotometer is one of the best professional solutions for print color measurement and color control for printing.

Datacolor

Datacolor is one of X-Rite’s main competitors, offering strong technological expertise and a significant global market share. Its Check 3 Handheld Color Spectrophotometer rivals the eXact 2 in terms of performance and is widely used across the printing industry for high-precision color control.

High-Value and Cost-Effective Brand

Linshang

Linshang is a manufacturer known for delivering high-quality, cost-effective colorimeters and spectrophotometers. With over a decade of optical instrument development experience, Linshang is committed to producing durable, high-performance instruments that bring measurable value to its customers. The company has served over 100,000 clients in more than 100 countries and is highly regarded for its innovation and service quality.

For printing applications, Linshang LS372 is designed specifically for spectrophotometer in printing use. It features the industry-standard D50 light source and a 4mm measuring aperture — ideal for checking color patches and control strips directly on the press. The LS372 combines accuracy, portability, and ease of use, making it a smart choice for small and medium-sized printing businesses seeking reliable print color measurement at an affordable price.

D50 standard lighting conditions, in line with ISO standards

3.5-inch smart touch screen

Built-in multiple standard electronic color cards

High precision, national first-class machine

Colorimeters and spectrophotometers have become essential tools for achieving digitalized and standardized color management in the printing industry. Choosing the right instrument helps printing companies quickly achieve the desired colors, reduce ink and paper waste during color matching, and lower production costs while improving color control efficiency and consistency. By using colorimeters and spectrophotometers, businesses can deliver high-quality, consistent printing results, enhance customer satisfaction, and strengthen their competitiveness in the printing market.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.

- What are the metal hardness testing methods?

- What Factors will Affect Paint Gloss?

- Car Paint Meter for Automotive Industry

- UV Power Puck | What are the Advantages of UV Printing Technology?

- Thermal Insulation Effect of Stick-film and Coated glass | Tint Tester

- Difference of LS116 Transmission & LS117 OD Meter