How to Choose the Right Ultrasonic Thickness Gauge – Manufacturer, Brand, and Price Insights

In the fields of petrochemical, shipbuilding, energy and power, aerospace, etc., ultrasonic thickness gauge (UTG) has become an indispensable non-destructive testing tool. However, facing the various equipment on the market, how to choose the most suitable instrument has become a key challenge-this is not only related to measurement accuracy and reliability, but also directly affects your inspection efficiency and cost-effectiveness. Choosing the right ultrasonic thickness gauge manufacturer, identifying high-quality ultrasonic thickness gauge brands, and understanding the price structure of ultrasonic thickness gauges are the core links to make wise decisions. This article will deeply analyze these three key dimensions to help you find the best solution that truly matches your industrial needs and budget range in the massive information.

I. What Is an Ultrasonic Thickness Gauge

An ultrasonic thickness gauge, also known as an ultrasonic thickness tester, ultrasonic thickness meter, and UT gauge, is a non-destructive testing instrument designed to measure the thickness of materials such as metal, plastic, glass, rubber, and more. Unlike traditional mechanical calipers or micrometers, ultrasonic thickness gauges do not require access to both sides of the material, so it's ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side.

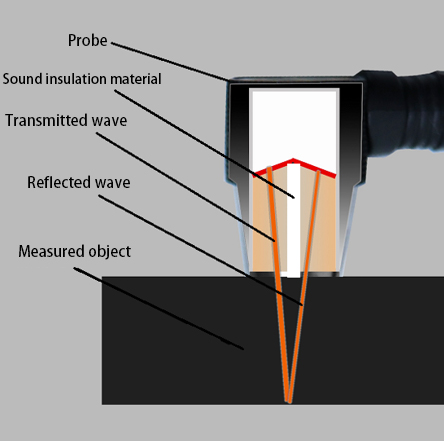

The instrument work based on the ultrasonic pulse reflection principl. A probe (or transducer) sends an ultrasonic pulse into the material. When the pulse hits the back wall or an internal boundary, it reflects back to the probe. The device then calculates the thickness using the formula:

Thickness = (Velocity of sound in material × Time) ÷ 2

Whether you are measuring corrosion loss, manufacturing defects, or coating thickness, an ultrasonic thickness tester offers a reliable, fast, and accurate solution — all without damaging the test object.

II.Understanding Different Types and Features of Ultrasonic Thickness Gauges

Before choosing a manufacturer, it's important to understand the different types of ultrasonic thickness gauges available on the market. These devices are not one-size-fits-all — their features and designs vary based on the specific application, probe type, and precision requirements. Knowing which model suits your needs can make the difference between accurate, reliable measurements and costly errors.

1. Common Types of Ultrasonic Thickness Gauges

-

Standard Ultrasonic Thickness Gauges

These are used for general-purpose thickness measurements of metals, plastics, and other homogeneous materials. They provide fast and reliable readings in typical industrial settings.

-

High Precision Ultrasonic Thickness Gauges

Designed for applications requiring extremely fine resolution (up to 0.001mm/1μm), such as precision components, thin films, and laboratory testing. These models are ideal when accuracy is critical.

-

Multi-Layer Ultrasonic Thickness Gauges

Advanced models capable of measuring multiple layers simultaneously, useful in detecting the thickness of coatings over base materials, such as painted metals.

2. Key Features to Consider

Measurement Range & Resolution: Make sure the gauge supports the thickness range of your target material with adequate resolution.

Material Compatibility: Look for devices that support a wide variety of materials, or allow you to manually adjust the sound velocity.

Calibration Options: Most ultrasonic thickness gauges support one-point or two-point calibration and include built-in reference blocks.

Data Storage & Output: For quality control and reporting, features like data logging, USB/Bluetooth transfer, and PC software are highly valuable.

Environmental Durability: For harsh environments, choose rugged designs with waterproof housings and durable keypads.

With such a wide range of types and technical features available, it's clear that choosing the right ultrasonic thickness gauge isn't just about the device — it's also about finding a manufacturer that understands your needs and offers tailored solutions.

Linshang LS213 Ultrasonic Thickness Gauge Feature Video

III. Choosing the Right Ultrasonic Thickness Gauge Manufacturer

Once you understand the different types and features of ultrasonic thickness gauges, the next step is choosing a reliable ultrasonic thickness gauge manufacturer. The quality, accuracy, and durability of your device heavily depend on the capabilities and credibility of the manufacturer behind it.

1. Why the Manufacturer Matters

-

Quality assurance - only reliable test data

Qualified ultrasonic thickness gauge manufacturers will use high-performance single crystal or dual crystal probes, low-noise circuit design, and ensure that the instrument can pass the inspection of the authoritative metrology institute to ensure the thickness measurement accuracy and repeatability.

-

Cost control - source manufacturer VS intermediate agent

Direct cooperation with the source manufacturer of ultrasonic thickness gauge can save layers of price increases, usually saving 20%-30% of the budget. And it can also provide OEM services to meet the needs of personalized customization, which are difficult for middlemen to achieve.

-

Perfect after-sales service - worry-free use

Manufacturers must provide services such as operation manuals or videos, remote fault diagnosis, and fast delivery of spare parts; slow after-sales response often means downtime losses.

2.Leading Ultrasonic Thickness Gauge Manufacturer in China

Linshang is a source manufacturer and supplier of ultrasonic thickness gauges that integrates R&D, production, sales and service. With strong technical strength and strict quality control, it ensures that every piece of equipment shipped out of the factory has high precision and long life. The company has a rich product line, covering a variety of single-layer thickness gauges (such as LS211, LS212, LS213), with a range of 0.8-600mm, a resolution of 0.001mm, and equipped with Bluetooth function, which can be connected to the APP, suitable for the detection of various materials such as steel plates, aluminum plates, glass, plastics, etc.; at the same time, the LS216 multi-layer ultrasonic thickness gauge is launched, which can realize the simultaneous measurement of multi-layer thickness to meet the needs of complex working conditions. Linshang Technology also provides flexible OEM customization services to help partners achieve product differentiation competition. The company has complete supporting pre-sales consultation and selection guidance, and has established a comprehensive after-sales service network to ensure that users enjoy efficient and professional technical support and maintenance services.

IV. Best Ultrasonic Thickness Gauge Brands in the Market

After evaluating user feedback, feature sets, and application flexibility, these brands represent some of the most trusted options in the ultrasonic thickness gauge market today. Whether you're looking for a high-end device for precision measurement or a cost-effective solution for routine inspections, these brands offer models to suit every need.

| Brand | Linshang | Olympus | DeFelsko | Dakota Ultrasonics |

| Overview | A rising Chinese brand known for cost-effective, high-performance thickness gauges | A global NDT leader offering advanced, high-precision devices trusted across critical industries | U.S.-based brand specializing in durable and accurate surface inspection instruments | Known for compact and rugged ultrasonic thickness testers for tough environments |

| Recommended Model | LS216 High Precision Ultrasonic Thickness Gauge | 38DL PLUS | PosiTector UTG Series | Dakota ZX |

| Why Recommend | Supports simultaneous three-layer measurement, ideal for coatings and composites | A flagship industrial-grade model with excellent stability and precision | Excellent for detecting corrosion/erosion-related material loss with high reliability | Offers affordable, portable options for quick field thickness checks |

| Key Features | - 1μm resolution with high-speed ADC sampling - Multi-layer readout - Touchscreen UI - Sound velocity library |

- Echo-to-echo mode - Multi-probe compatibility - Designed for harsh environments |

- Echo-to-echo mode - Interchangeable probes - Data storage and output |

- Rugged design - Fast response - Optimized for cost-effective industrial use |

V. How Much Does an Ultrasonic Thickness Gauge Cost?

The price of an ultrasonic thickness gauge varies significantly depending on its features, measurement capabilities, and target application. Whether you're looking for a simple handheld tester or a high-end multi-functional instrument, understanding the typical pricing tiers can help you make a more informed purchasing decision.

1. Price Ranges by Function and Application

-

Entry-Level Models ($70–$170)

These affordable models are ideal for measuring the thickness of standard materials such as metal sheets, plastics, and coatings. They usually offer basic functions and lower resolution, and are not suitable for ultra-thin or very thick materials.

-

Mid-Range Models ($170–$850)

These gauges support auto gain adjustment, large memory for data storage, customizable sound velocity settings, backlit displays, and often come with PC software or mobile app support. They can measure a wide variety of materials, including plastics, fiberglass, and rubber.

-

High-End Models ($850–$2,800+)

Advanced models offer features like A-scan/B-scan imaging, multi-layer thickness measurement, and integration with third-party software or industrial systems. These are suitable for complex composite materials, precision quality control, and research-grade applications.

2. Which Price Tier Is Right for You?

-

Just Measuring Metal Plates? — Go with Entry to Mid-Level

If your primary goal is to measure the thickness of steel, aluminum, or other metals, an affordable ultrasonic wall thickness gauge in the lower price range will be sufficient. Complex features are not required — reliability and simplicity matter most.

-

Need to Measure Plastics, Fiberglass, or Rubber? — Choose Mid-Range

These materials have different sound velocities compared to metals. For accurate readings, you'll need a model that supports velocity customization — either through a built-in material library or manual input. Without this function, measurement errors are likely due to sound speed variation in different materials.

-

Need to Measure Multi-Layer Thickness? — Choose a Multi-Layer Gauge

For example, the LS216 Multi-Layer Ultrasonic Thickness Gauge by Linshang supports simultaneous measurement of up to three layers. It's one of the few devices on the market offering this capability, ideal for analyzing composite structures like honeycomb panels or sandwich materials.

-

For R&D or High-Standard Quality Control? — Go High-End

In laboratory or high-precision manufacturing environments, advanced features like A-scan/B-scan imaging and echo waveform display are essential. These help users detect internal defects and ensure measurement accuracy. High-end models also offer data storage and export functions, making them suitable for scientific research, aerospace, and professional QA processes.

By understanding your material type, measurement needs, and working environment, you can select an ultrasonic thickness tester that offers the best balance between price and performance — whether it's an affordable device for simple tasks or a high-precision ultrasonic thickness gauge for specialized applications.

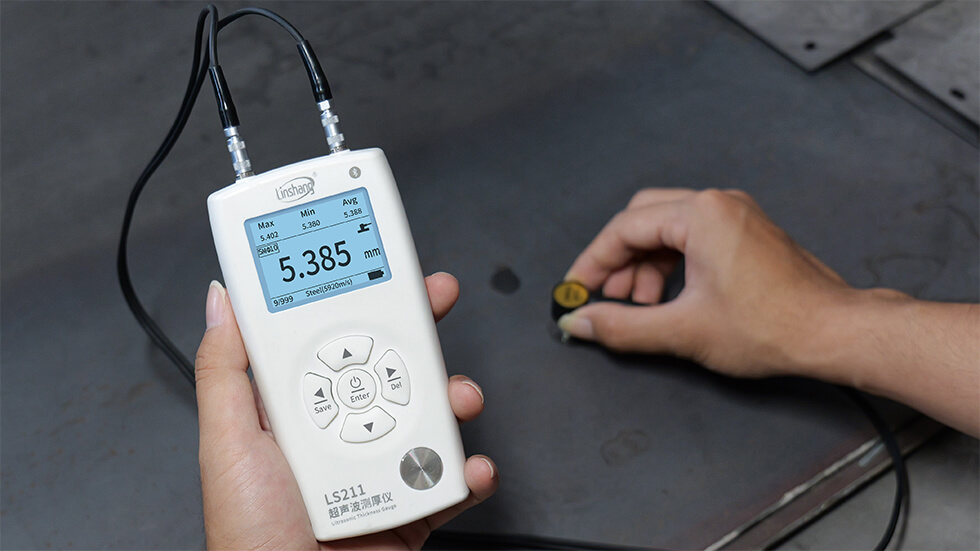

Ultrasonic thickness gauge testing steel plate

Ultrasonic thickness gauge testing glass

Ultrasonic thickness gauge testing multi-layer materials

VI. Tips for Buying the Right Thickness Gauge for Your Application

When purchasing an ultrasonic thickness gauge, finding the best value for your needs is far more important than chasing high-end features you may never use. A well-matched model offers better long-term reliability, ease of use, and cost-efficiency. Here are several practical tips to help you make the right choice:

-

Choose Features That Are “Just Right”

Start by defining your core measurement needs. Avoid paying for advanced functions that don't serve your actual use cases. For example, if you only need to measure basic metal thickness, there's no need for waveform display or multi-layer capabilities. Simplicity can be a strength when the focus is on reliability and speed.

-

Prioritize Brand Reliability

A reliable ultrasonic thickness gauge brand means more than just a logo — it ensures accurate readings, durable build quality, and less downtime due to equipment failure. Trusted brands are backed by years of technical expertise and user feedback.

One such example is Linshang, a well-established Chinese manufacturer that offers a complete range of ultrasonic thickness testers from budget models to high-end solutions. Known for their stable performance and user-friendly design, Linshang’s products are widely used in industrial environments.

-

Recommended Linshang Models:

LS211: Measuring range up to 600mm with a resolution of 0.001mm. Ideal for thick metal parts and large structural components.

LS212: 350mm range with 0.001mm resolution, offering high accuracy and wide applicability for most industrial materials.

LS213: Also with a 350mm range but 0.01mm resolution. A cost-effective choice for users who don’t require ultra-high resolution.

Note: All three models above support auto gain adjustment, quality control (QC) mode, smartphone app connectivity, 999-group data storage, and max/min statistics, meeting various industrial measurement needs.

LS216: A high-end model that supports multi-layer measurement (up to three layers simultaneously), using high-speed ADS data acquisition and offering a resolution of 1μm (0.001mm). The device also displays real-time waveform, making it perfect for composite materials and multilayer coatings.

-

Ensure After-Sales Support Is in Place

Even the best instrument needs proper support. A good manufacturer will offer technical assistance, calibration services, and easy access to spare parts like probes. Companies like Linshang provide fast-response support, online documentation, and a service team to ensure your device runs smoothly over the long term.

High-speed ADC data acquisition, resolution up to 1μm

Color touchscreen for easy operation

Wide range with built-in sound velocities for over 20 materials

Waveform display ensures accurate layer thickness readings

With four kinds of probes, measuring a wide range of materials

Two measurement modes: QC Mode/Statistics Mode

Large measuring range: 0.8mm-600mm and high-sensitive dual-crystal probe

Automatic Gain switchable

Measure 0.8-350mm material, resolution up to 0.001mm

Two measurement modes: QC Mode/Statistics Mode

Four types of probes applicable, measuring various materials

Automatic Gain switchable

Precision ultrasonic thickness gauge provide fast, accurate readings

Two measurement modes: QC Mode/Statistics Mode

High-sensitive dual-crystal probe

Automatic Gain switchable

VIII. Frequently Asked Questions (FAQs)

-

1. What materials can ultrasonic thickness gauge test?

The ultrasonic thickness gauge uses the pulse reflection ultrasonic measurement principle to measure the thickness. Any material that can make ultrasonic waves propagate at a constant speed can be measured by this principle. The measured materials are very wide, suitable for testing the thickness of any good ultrasonic conductor such as various metals, plastics, ceramics, glass, etc.

-

2.Does the instrument need to be calibrated before each use?

Not necessarily. The ultrasonic thickness gauge has been calibrated at the factory and does not need to be calibrated frequently.

-

3. Can I use the gauge for corrosion or wall thinning inspection?

Yes. Our ultrasonic thickness gauges are ideal for you to monitor remaining wall thickness without cutting or damaging the material, making them perfect for non-destructive testing in maintenance and safety inspections.

-

4. What’s the difference between single-layer and multi-layer measurement?

Single-layer measures the total thickness of one material. Multi-layer models like LS216 ultrasonic thickness gauge can detect up to three separate layers in composite materials — ideal for coatings, laminates, or multi-layer plastic sheets.

-

5. Can I use the device on curved or rough surfaces?

It can be used to measure curved surfaces, but not rough surfaces. When measuring curved surfaces, the split surface of the probe should be perpendicular to the axis of the curved surface.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.