How does fabric shading come about? What can fabric colorimeters do?

In the printing and dyeing cloth industry, color difference is a common quality defect. There are many reasons for the color difference, which are related to the raw materials and dyeing process of textile fabrics. In the color difference detection using cloth colorimeter, printing and dyeing cloth color difference control in a reasonable range, to ensure the quality of products.

Fabric shading cause

In the textile industry, the types of fabrics are very diverse, from the general classification, roughly cotton, linen, silk, wool, leather, chemical fiber, blended. Due to the different fibers of various fabrics, the fuel and process equipment used in dyeing are different, and there are different requirements and characteristics in dyeing processing, so the causes of color difference are various, which can be roughly divided into the following reasons:

1. Uneven distribution of dye

If the dye is not evenly distributed in each part of the fabric before fixation, the color will inevitably form a color difference after fixation. This phenomenon is mainly caused by the properties of the fabric itself, the uneven absorption of the fabric, and the inconsistent rate and degree of pre-drying.

2. Different degrees of fixation

Although the dye distribution on the fabric is uniform in the early stage, but in the fixing process, if the conditions are not properly controlled (such as temperature, time, dye concentration, etc.), the dye on some parts of the fabric is not sufficiently fixed, which will be removed in the post-treatment soap, and the color difference will be produced.

3. Color light variation

This difference is not caused by the uneven distribution of dyes on the fabric, but due to some reasons caused by the change of the color of some dyes on the fabric, resulting in color difference.

Fabric shading prevention method

In order to ensure the color difference of the printing and dyeing cloth within a reasonable range, we need to verify and analyze the color difference of each link of the dyeing process, in which the cloth colorimeter plays a great role.

1. Prepare materials

A color, regardless of batch size, the first requirement is the same batch, color light, the same concentration of dye. Otherwise, adjust the formula when dyeing, and put into production after the sample. In the material preparation stage, the colorimeter can be used to increase the control of the color of the dye stock solution. For example, the colorimeter can be used to measure the color and record the dye color formula to form a standardized operation. In addition, part of the colorimeter color contrast has a color bias prompt, according to the prompt information to adjust the color, so as to control the color difference value. Strict control of the color difference of textile raw materials is the first step to control the color difference of printing and dyeing cloth.

2. Sample

The printing and dyeing fabric samples were prepared in strict accordance with the dosage and operation procedure of the formula. The process and technical conditions of the sample, including pressure, speed, temperature and concentration, must be the same as that of normal production. In this way, the color difference of the sample can be verified to avoid the loss caused by mass production color difference. In the sample stage, if the sample is passed, the color of the standard can be stored with the colorimeter to ensure the consistency of the subsequent printing and dyeing. After the color is stored, it can also be shared with other colorimeters or archived to customers. This can also solve the problem of fading of physical samples.

3. Monitoring

Although the color difference on the formula can be verified through the sample to a certain extent, in the actual production process, because the production process of different batches is difficult to be completely consistent, it will be affected by various factors such as manual and equipment, so there will still be some color difference in mass production. Therefore, professional color verification equipment is needed. The cloth colorimeter is used for sampling inspection of the products produced. If there is an obvious color difference problem, it is necessary to find the cause of the color difference in time and strictly control the color difference of printing and dyeing cloth.

If there is no sample sample, you can store the standard color in advance, and then add the standard color from the folder when measuring. In the cloth color difference detection, the cloth colorimeter can more easily and quickly detect the color difference that can not be identified by the naked eye, so as to control the quality of the textile fabric. In order to ensure the consistency of product color, reduce the corresponding loss. In addition, the QC mode can also be opened and used with APP or PC software to define acceptable color difference threshold according to the actual situation and quickly determine whether a batch of finished products is qualified.

Suitable for testing materials with texture or rough surface

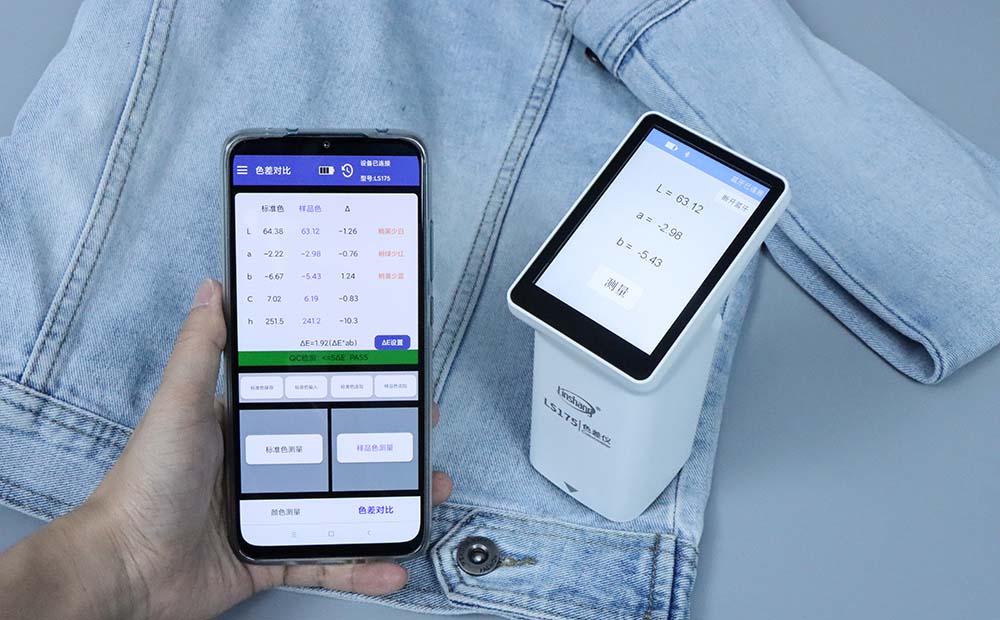

The colorimeter in the above cloth color difference detection process is recommended to use the LS175 intelligent colorimeter in the forest. The following advantages can meet the needs of fabric detection:

Large diameter measurement, suitable for fabric testing;

Light body, suitable for carrying to the workshop for color detection;

Large LCD display, can restore the measured color, easy to operate;

The instrument can store up to a thousand color data and color contrast data;

Save the standard function, no need to carry physical fabric samples, no need to worry about the loss of standards or fading problems;

Bluetooth mode, color sharing with APP;

With PC software use, easy to export color, combined with dyeing formula in the computer archive.

The above is the cause of cloth color difference and all the content of the application of cloth colorimeter. Fabric shading is inevitable. In order to ensure the quality clearance, we need layers of checks and professional equipment to make the production work twice the result with half the effort.

- How to Choose UV Intensity Meter for 254nm Germicidal Lamp?

- How to Distinguish Fireproof Paint by Glossiness Detection?

- Painting Thickness Meter | How are fire-resistant coatings classified?

- How Do You Choose A Paint Thickness Measurement Tool?

- Linshang Paint Thickness Meters For Sales

- Rating of the UV Radiation Index