What Is An Ultrasonic Hardness Tester?

Hardness testing is essential in many manufacturing and quality control processes. It helps quickly identify defective products and prevents larger economic losses later. However, traditional hardness testers, such as Rockwell and Vickers, face limitations. Large parts cannot always be cut for testing, finished components cannot have visible indentations, and some measurements need to be done on-site in complex locations.

A portable ultrasonic hardness tester offers a solution. This ultrasonic hardness tester uses a non-destructive testing method to quickly measure the hardness of various metals without causing any damage. Now we will explain the ultrasonic hardness testing method, its working principle, key features, typical applications, and tips on how to choose the right ultrasonic hardness tester for your needs.

What is an ultrasonic hardness tester

An ultrasonic hardness tester is a portable device that measures the hardness of metals using a non-destructive method. It is ideal for small parts, thin materials, and complex components.

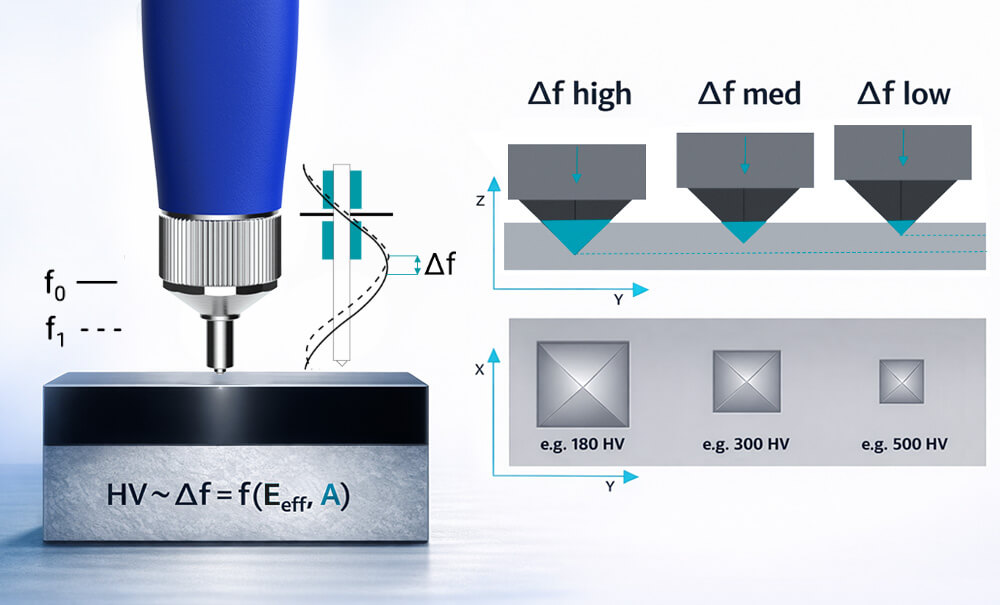

Principle: how an ultrasonic hardness tester works

The ultrasonic hardness tester uses the ultrasonic contact impedance hardness tester method. A diamond-tipped probe, often a square pyramid, is pressed into the material under a specific test force. At the same time, the probe is vibrated at ultrasonic frequencies. The contact between the probe and the material creates mechanical impedance, which changes the probe’s resonance frequency. This frequency shift depends on the indentation area and the effective elastic modulus of the system. By accurately measuring this change, the hardness value of the material can be calculated.

In simple terms: when you apply a certain pressure to a material, its hardness or softness changes its ability to resist the vibration of the probe—this is known as contact impedance. The softer the material, the larger the indentation, and the more it “absorbs” the probe’s vibration. Imagine pressing your hand on a soft sofa—the vibrations are quickly damped. The ultrasonic hardness tester measures the frequency change and converts it into a precise hardness value.

Ultrasonic hardness tester vs. Other hardness testers

If you need fast on-site hardness testing without damaging the part, or want to know the material hardness anytime and anywhere, an ultrasonic hardness tester is the best choice.

| Tester | Surface Damage | Suitability for Thin Parts | Portability | Typical Applications |

|---|---|---|---|---|

| Ultrasonic Hardness Tester | ★★★★★ Micro-indentations, almost invisible. No effect on most finished parts. True micro-damage or near non-destructive testing. |

★★★★★ Excellent. Works on thin sheets, wires, thin tubes, edges, and small bearings. |

★★★★★ Handheld or portable. Ideal for large, installed, or hard-to-reach parts on-site. |

Highly portable, non-destructive and accurate. Best choice for on-site hardness measurement. |

| Rockwell Hardness Tester | ★★ Deep indentation, visible, destructive. Even surface Rockwell scales (HR15N) mainly for thicker treated layers. |

★ Poor. Deep indentations can break or deform thin parts. Data may be inaccurate. Even surface Rockwell scales remain impractical. |

★★★ Limited portability. Mostly large machines; portable versions exist but with reduced accuracy and field usability. |

Suitable for thicker samples, not ideal for high-value finished parts. |

| Brinell Hardness Tester | ★ Very large indentation, highly destructive. Destroys surface and mechanical properties. |

★ Not suitable for thin parts. Large spherical indentations crush or deform thin materials. |

★ One of the heaviest machines. Needs hydraulic or mechanical loading. Fixed use only. |

Designed for average hardness of coarse grain materials. |

| Vickers Hardness Tester | ★★★★ Small but visible indentation. Still considered destructive for finished surfaces. |

★★★★★ Excellent for thin layers using Micro-Vickers (low loads, e.g., 10 gf). Ideal for coating hardness measurement. The authoritative method for lab microhardness testing. |

★ Typical fixed benchtop device: bulky, requiring workpieces to be cut or sampled for testing, with no portability whatsoever. |

Suitable for precision lab testing. |

Advantages of testing hardness using ultrasonic hardness testers

1. Non-destructive testing

An ultrasonic hardness tester uses high-frequency ultrasonic vibration to measure hardness. The indentation left on the surface is extremely small, usually at the micron level that invisible to the naked eye. The test does not affect the appearance or performance of the part. This makes it a true non-destructive testing method, ideal for finished parts, high-value components, and critical metal parts.

2. Suitable for thin materials and small parts

Traditional testers like Brinell or Rockwell need enough material thickness to support the indentation and thin parts often cannot be tested accurately. The ultrasonic hardness testing method works differently. It calculates hardness from high-frequency micro-vibration, so thickness requirements are very low. Thin sheets, thin-walled parts, and small components can be tested reliably. For ultra-thin materials, coupling can further improve stability and accuracy.

3. Portable and ideal for on-site testing

Most ultrasonic hardness testers are designed as handheld devices. A modern ultrasonic portable hardness tester is compact and easy to use. Measurements are fast and efficient. Compared with bench-type testers, it is much better suited for workshops, construction sites, and on-site inspection of installed equipment.

4. High accuracy and good repeatability

By measuring changes in ultrasonic vibration frequency, the ultrasonic contact impedance hardness tester delivers high resolution and excellent repeatability. It meets industrial accuracy requirements and can be verified by authorized metrology institutes. This makes it reliable for quality control and production inspection.

5. Multiple hardness scale conversion

Ultrasonic hardness testers usually support multiple hardness scales in one device. These include Vickers (HV), Rockwell (HRC, HRB, HRA, HRE, HRF), Brinell (HB), Leeb (HL), and Shore (HS). One instrument can meet different standards and industry needs. Engineers and inspectors do not need manual conversion tables, which greatly improves testing efficiency.

Applications of ultrasonic hardness testers

Based on the ultrasonic contact impedance principle, the ultrasonic hardness tester combines five key advantages: non-destructive testing, suitability for thin parts, high accuracy, portability, and intelligent hardness scale conversion. This makes it suitable for a wide range of applications.

Complex and hard-to-reach areas

It can accurately measure hardness in areas where traditional testers cannot reach, such as flange edges, gear tops, gear slots, and mold cavities. These locations often have limited space or complex geometry.

Thin, small, and lightweight components

With very low requirements for material thickness and mass, the ultrasonic hardness testing method is ideal for bearings, thin-walled tubes, metal sheets, drill bits, and cutting inserts.

Final inspection of finished parts

The near non-destructive nature of an ultrasonic hardness tester means there is almost no impact on appearance or performance. This makes it well suited for finished products and precision components that require surface protection.

On-site testing of large and installed equipment

Thanks to its portable design, an ultrasonic portable hardness tester can be used directly on the equipment without disassembly or cutting. It is suitable for wheel hubs, in-service pressure vessels, pipelines, and other large or fixed structures.

In summary, the ultrasonic hardness tester effectively solves three common problems in traditional hardness testing: parts that cannot be tested due to limited space or very small size, parts that must not be damaged during testing, and large or fixed equipment that is difficult to measure. It has become an essential tool for modern industrial hardness quality control.

How to choose the right ultrasonic hardness tester

If you are planning to buy an ultrasonic hardness tester but are unsure how to choose, consider the following key points:

Know your material and hardness scale

Start by identifying the types of materials you will test and the hardness scales you need. Make sure the tester you choose supports the specific material and hardness conversion scales you require.

Determine the hardness range

Estimate the hardness range you expect to measure. Choose a device with a measurement range that covers your testing needs.

Check accuracy and repeatability

Different models offer varying levels of precision. Ensure the ultrasonic tester you select delivers the level of accuracy and repeatability required for your application.

Consider price and value

Price is an important factor. Look for an ultrasonic hardness tester that offers good value – reliable performance, essential features, and a reasonable cost.

Choose a trusted supplier

A good ultrasonic hardness tester supplier can make a big difference. A reputable manufacturer often provides reliable product quality, strong quality control, and good pre-sales and after-sales support.

Best ultrasonic portable hardness tester suppliers

The Linshang LS256 is a compact, all-in-one ultrasonic hardness tester that is easy to carry for fast on-site testing. It supports nine hardness scales based on different metals, including HV, HRC, HRB, HRA, HRE, HRF, HB, HL, and HS. The LS256 delivers wide application range with accuracy of ±2.5 HRC. Its lightweight design makes it a popular ultrasonic portable hardness tester for general metal testing. The price is around $500 USD.

NOVOTEST T-U3 UCI Hardness Tester

The NOVOTEST T-U3 features a split design with three interchangeable probes at 10N, 50N, and 98N test forces. This versatility allows testing in different scenarios and on various materials. It can measure HRC, HB, and HV hardness scales as well as tensile strength in MPa. Accuracy is ±2 HRC. As a more advanced ultrasonic contact impedance hardness tester, it is priced around $4,000 USD.

SONOHARD SH-21A Ultrasonic Hardness Tester

The SONOHARD SH-21A also uses a split design and includes 10N and 20N probes for flexible testing applications. It supports HRC, HV, HS, and HB hardness scales, along with tensile strength in N/mm². With high precision at ±1.0 HRC, this model is ideal for more demanding hardness testing work. It is typically priced around $4,800 USD.

Proceq Equotip Live UCI Hardness Tester

Portable wireless probe, requires connection to a mobile app for use. Capable of detecting eight hardness scales—HV, HL, HB, HRC, HRA, HRB, HR15N, HR15T—as well as tensile strength MPa (σ1, σ2, σ3). With high measurement accuracy ±2%, and price is approximately $6,000 USD.

Linshang LS256 Ultrasonic Hardness Tester is a cost-effective choice and one of the best ultrasonic hardness testers for everyday metal testing, especially for users seeking a portable solution.

Tips and FAQs for using an ultrasonic hardness tester

Using an ultrasonic hardness tester is simple. Press the probe vertically onto the sample and keep it steady. The hardness value will appear on the screen automatically. To achieve accurate and stable results, please note the following points:

When powering on or calibrating, the probe must be suspended in the air. Do not let it touch the sample, table, or any object. Even light contact can affect the ultrasonic vibration frequency and lead to inaccurate results later.

Before testing, choose the correct material type and hardness scale. If the material is not available in the built-in list, the LS256 allows custom material setup. After calibration with a reference sample of known hardness, the tester can measure this material accurately.

The LS256 ultrasonic portable hardness tester can easily measure metal samples with a thickness of 5 mm or more and a weight above 500 g. For parts that do not meet these conditions, measurements are also supported after coupling preparation.

The ultrasonic hardness testing method is sensitive to surface condition. If the surface is rough, polishing or light grinding is recommended before testing to obtain more reliable data.

If the instrument has not been used for a long time or if the readings seem inaccurate, recalibration is recommended. The LS256 comes with a standard hardness block, allowing users to perform calibration easily.

-

What to do if LS256 ultrasonic hardness tester results are unstable?

First, check whether the measurement is performed strictly according to the recommended procedure above.

If the results are still unstable, the most common reason is that the probe is not pressed vertically and steadily onto the sample surface. In this case, it is recommended to use the dedicated Hand Pressure Test Stand for the LS256, which reduces instability caused by manual pressing and improves measurement accuracy and repeatability.

-

Is the LS256 ultrasonic hardness tester non-destructive?

Yes. The indentation produced by the LS256 ultrasonic contact impedance hardness tester is at the micron level and is almost invisible to the naked eye. It does not affect the appearance or performance of the workpiece, making it a true non-destructive ultrasonic hardness testing method, ideal for finished and high-value parts.

-

Can the LS256 pass calibration by a metrology institute?

Yes. The LS256 ultrasonic hardness tester can pass inspection and calibration by authorized metrology institutes, ensuring stable, accurate, and traceable hardness measurement results.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.