Ultrasonic Thickness Gauge: A Complete Guide

The ultrasonic thickness gauge (UT gauge) is a non-destructive testing instrument that measures the thickness of metals (such as steel, aluminum, copper), plastics, glass, and other materials using ultrasonic technology. It is widely used in the automotive, aerospace, and manufacturing industries and is particularly ideal for measuring the wall thickness of pipes, tanks, and pressure vessels to detect corrosion and wear. Choosing the right ultrasonic thickness gauge is crucial. Before making a purchase, it is important to understand its working principle, key features, application areas, and usage methods. Once your specific needs are clear, selecting a professional and reliable manufacturer will ensure product quality as well as comprehensive pre-sales and after-sales support.

What is an ultrasonic thickness gauge?

Ultrasonic thickness gauges can measure the thickness of various metals, such as steel, stainless steel, and aluminum, as well as non-metallic materials like ceramics, plastics, and glass, as long as the ultrasonic waves can propagate evenly and the material’s top and bottom surfaces are parallel or coaxial. During the production of new equipment materials, ultrasonic thickness gauges can verify whether the material thickness meets the required standards, ensuring product quality. Beyond production, they are also used to monitor wear and corrosion in materials during use, evaluate the remaining service life of equipment, and provide a reliable basis for maintenance and management.

How do ultrasonic thickness gauges work?

There are many ultrasonic thickness gauges on the market. Based on their measurement principles, they can be mainly divided into three types: pulse-echo ultrasonic thickness gauges, resonance ultrasonic thickness gauges, and through-transmission ultrasonic thickness gauges.

1.Pulse-Echo Ultrasonic Thickness Gauge:

The probe emits high-frequency ultrasonic waves into the material, which propagate inside and reflect off the bottom or internal interfaces, then are received by the probe. The material thickness is calculated by measuring the time interval between transmission and reception. This type is suitable for most homogeneous materials such as metals, plastics, and glass.

Single-crystal probe: Uses a single piezoelectric crystal as both transmitter and receiver. The crystal emits ultrasonic pulses, which are reflected from the bottom surface of the material and received by the same crystal. It requires a smooth surface, offers high resolution, and is suitable for measuring thin materials and precision components.

Dual-crystal probe: Uses separate transmitting and receiving crystals. The transmitter emits ultrasonic waves, while the receiver captures the reflected signals. This separation reduces interference and provides better stability, but it is not suitable for measuring extremely thin materials.

2.Resonance Ultrasonic Thickness Gauge:

The probe emits ultrasonic waves with continuously varying frequencies. When the wavelength of the ultrasonic wave is an integer multiple of the material thickness, resonance occurs. The thickness is determined by detecting the resonance frequency. This type is particularly suitable for very thin materials with high surface finish requirements, but it is not suitable for multilayer or composite materials.

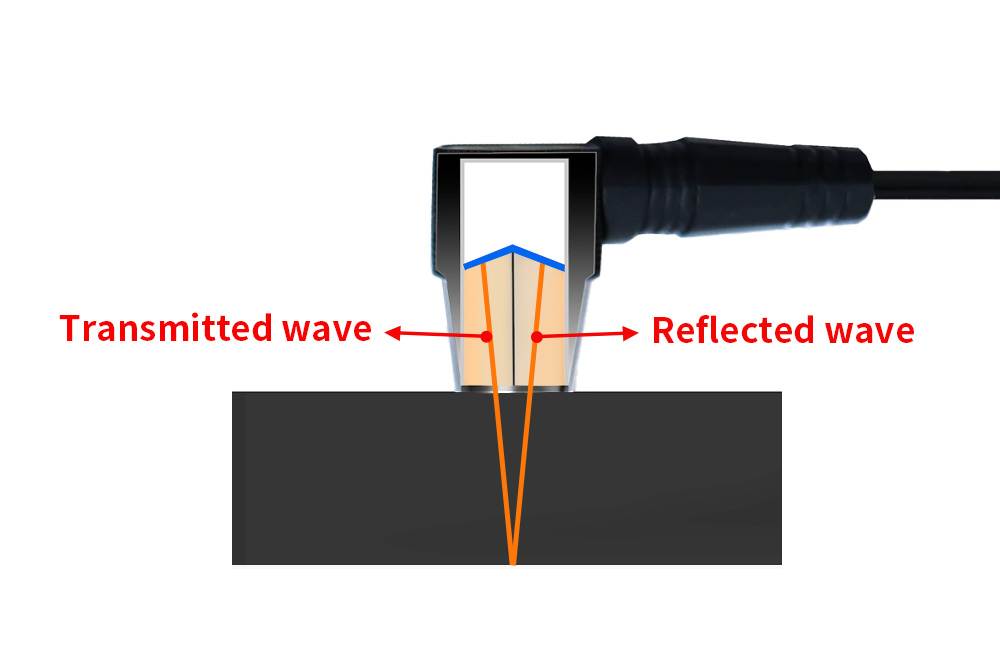

3.Through-Transmission Ultrasonic Thickness Gauge:

Uses a dual-probe configuration, with one probe transmitting ultrasonic waves and the other receiving them. The thickness is calculated based on the energy attenuation or time delay of the waves passing through the material, combined with the speed of sound. This method is similar to pulse-echo but does not rely on reflections and requires access to both sides of the material, limiting its application scenarios.

Benefits of pulse-echo ultrasonic thickness gauges

The pulse-echo ultrasonic thickness gauge is the most widely used thickness measurement technology in industry today. It plays an important role in equipment maintenance, quality control, and safety inspections. Its main advantages include:

Non-destructive testing: It does not require cutting, drilling, or damaging the surface of the tested object, making it ideal for long-term and periodic inspections. Reliable results can be obtained while keeping the structure safe and intact.

Single-side measurement: Only one side of the material is needed for measurement, which makes testing highly flexible. For pipelines, tanks, closed containers, and large machinery that cannot be accessed from both sides, inspectors can quickly and accurately measure thickness without disassembly, greatly improving efficiency.

Wide application range:This gauge can measure common metals such as steel, stainless steel, and aluminum, as well as non-metals like plastics, glass, and ceramics. Most devices have preset sound velocity values for common materials, while custom velocity settings allow accurate measurement under complex conditions and with special materials.

Portable and easy to use: Most pulse-echo ultrasonic thickness gauges are handheld and lightweight, making them convenient for field use. Measurements can be completed in just a few simple steps. Advanced models may also feature large displays, data storage, and Bluetooth transmission, providing greater convenience and efficiency for industrial applications.

What is an ultrasonic thickness gauge used for?

Ultrasonic thickness gauges, with their advantages of non-destructive testing and easy operation, play an important role in many fields, including industrial manufacturing quality control, equipment maintenance, aerospace and ship inspection, and construction engineering.

-

Industrial manufacturing quality control

Ultrasonic thickness gauges are widely used in the production of steel, aluminum, stainless steel plates, and pipes, allowing fast and accurate thickness measurement. They are also applied to plastics, molded parts, and glass, ensuring uniform thickness and compliance with production standards.

-

Industrial maintenance monitoring

In industries such as oil, chemical, and power, equipment like pipelines, pressure vessels, and storage tanks gradually wear down due to corrosion, high temperature, high pressure, or harsh environments. For example, natural gas pipelines may corrode over time, posing risks of leakage or explosion if not detected in time. The non-destructive nature of ultrasonic thickness gauges makes them ideal for regular corrosion monitoring and for developing scientific maintenance plans.

-

Aerospace and ship inspection

In aerospace, parts such as wings, fuselage, tail sections, and engine components are exposed to airflow impact and high pressure, which can lead to thinning and corrosion. Ultrasonic thickness gauges enable fast, non-destructive thickness measurement of these critical parts, helping engineers detect potential risks early and prevent accidents. In shipbuilding, hull steel plates are highly prone to corrosion due to constant contact with seawater. Ultrasonic thickness measurement allows accurate assessment of remaining thickness, supporting repair and anti-corrosion work and extending the vessel’s service life.

-

Construction engineering inspection

In large-scale construction projects, such as bridges, steel structures may gradually thin or weaken due to vehicle loads, wind, rain, and corrosion. Ultrasonic thickness gauges can accurately measure beams and plates without damaging the structure, allowing evaluation of thickness and corrosion levels. Regular inspections help monitor structural health, enable timely reinforcement and repair, and ensure the safety and stability of construction projects.

How to use an ultrasonic thickness gauge?

After learning about the basic information and applications of an ultrasonic thickness gauge, you may wonder: How do you actually use it? The following will take the Linshang ultrasonic thickness gauge as an example to explain how to calibrate the device and how to measure the thickness of an object with it.

How to calibrate ultrasonic thickness gauge?

To ensure accurate measurement results, it is recommended to calibrate the ultrasonic thickness gauge before use. The steps are as follows:

Apply a small amount of coupling gel to the built-in standard test block.

Firmly press the probe against the surface of the standard block and keep it steady. When the coupling icon appears at the top right corner of the screen, it indicates proper contact. The progress bar at the bottom will begin flashing, showing that calibration is in progress.

When the progress bar stops flashing and a beep sounds, the screen will show “Calibration Complete.” At this point, you can remove the probe from the standard block.

The screen will automatically switch to the measurement interface, displaying the data from the previous measurement. You can now begin measuring the thickness of your material.

How to measure thickness using an ultrasonic thickness gauge?

Before measuring, determine the material you want to measure. Note that only materials where ultrasonic waves can travel at a constant speed can be measured with an ultrasonic thickness gauge.

On the sound velocity setting screen, you will see several built-in sound velocity options for different materials. Check if your material is listed. If it is, simply select the corresponding sound velocity.

Next, apply a small amount of couplant to the surface of the test material.

Press the probe firmly against the material. When the coupling symbol appears in the top-right corner of the screen and the data bar “----” starts flashing, the measurement is in progress.

When you hear a beep, the test is complete, and the result will be displayed on the screen.

If the sound velocity you need is not available, you can set it using a sample of known thickness. Select a sample made of the same material as the test object, with a thickness that is already known. Apply a small amount of couplant to the sample, place the probe on it, and take a measurement. Then, use the up and down keys to adjust the displayed thickness on the screen to match the actual thickness of the sample. The instrument will then calculate the correct sound velocity for that material.

If you already know the material’s sound velocity, you can also enter it manually through the sound velocity setting.

After setting the velocity, you can measure the thickness of the test material in the same way as described above.

input the thickness to obtain the sound velocity.

of the material to be tested.

Note: When using a dual-crystal ultrasonic thickness gauge to measure curved materials, such as the thickness of a pipe, try to keep the transmitting and receiving surfaces on the same horizontal plane. This will ensure more accurate measurement results.

How to choose the right ultrasonic thickness gauge?

Choosing the right ultrasonic thickness gauge is crucial for industrial production and equipment maintenance. The following points can serve as a reference:

1. Identify measurement requirements

First, determine the type of material to be tested: is it metal (e.g., steel, aluminum, copper), non-metal (e.g., plastic, glass, ceramics), or composite? What is the approximate thickness—thin or thick? What is the surface condition—rough or smooth? Is there a coating? Is the material high-temperature?

2. Choose the appropriate probe

Different probes are suitable for different situations. Some ultrasonic thickness gauges (such as the LS212) offer multiple probe options for flexible use.

Standard probe: Suitable for regular workpieces and most general measurements.

Micro-dliameter probe: Small probe size, ideal for curved surfaces or small components.

Coarse-crystal probe: Designed for rough surfaces, such as cast iron or materials with large crystal grains.

High-temperature probe: Can measure materials with surface temperatures up to 500°C.

3. Consider additional features

Coating-penetration mode: Measures substrate thickness without removing the coating.

Data storage and transfer: Supports saving multiple measurements and exporting via Bluetooth or USB for easy recording and analysis.

After fully understanding your measurement needs and required features, the next step is to select a professional and reliable ultrasonic thickness gauge manufacturer to ensure product quality and complete after-sales service. Several leading manufacturers will be introduced next.

Leading ultrasonic thickness gauge manufacturers

1. Olympus Corporation:

Olympus is a world-leading brand in non-destructive testing. Its ultrasonic thickness gauges are known for high accuracy and stability, making them suitable for demanding industrial environments and a wide range of applications. They are widely used in industries such as petrochemicals, aviation, shipbuilding, and metal processing. With their superior performance, Olympus gauges are also ideal for high-end research and ultra-precision testing in aerospace and other advanced fields.

Price range: $1800-$8800

2. Linshang:

Linshang Technology Co., Ltd. is a professional manufacturer in China’s testing instrument industry, with over 17 years of experience. Its ultrasonic thickness gauges are well known for their high cost-performance and easy operation, making them ideal for daily inspection and quality control. Linshang has developed multiple models with complete functions and strong practicality, suitable for both single-material and composite thickness measurement.

Price range: $100-$1000

3. DeFelsko Corporation:

DeFelsko is a company specializing in material measurement and quality control instruments. Its ultrasonic thickness gauges are also professional and reliable, well known for their portability, ease of use, and durability. They enjoy a strong reputation in manufacturing and industrial quality management.

Price range: $1100-$3000

4. Dakota Ultrasonics:

Dakota is a professional U.S. manufacturer of ultrasonic testing equipment, specializing in ultrasonic thickness gauges and non-destructive testing instruments. The company emphasizes reliability and accuracy for industrial field applications. Its devices are widely used in pipelines, pressure vessels, and industrial maintenance.

Price range: $1000-$4000

5. Karl Deutsch:

Karl Deutsch is a German manufacturer focused on the research and production of non-destructive testing (NDT) instruments. Its ultrasonic thickness gauges are well known for high accuracy and durability, enjoying a strong reputation in Europe, especially in the steel and automotive industries.

Based on a comparison of ultrasonic thickness gauge brands, we can see that for typical industrial measurement scenarios—such as pipelines, construction materials production, and equipment maintenance—Linshang gauges fully meet customer needs and stand out for their high cost-performance ratio. For high-precision laboratory measurements or advanced fields like aerospace, international brands such as Olympus have a clear advantage. When choosing an ultrasonic thickness gauge, it is important to consider your specific needs and select the most suitable brand and manufacturer.

From industrial manufacturing sites to ongoing maintenance of production components, ultrasonic testing has become an indispensable tool in modern industry. Fast and accurate on-site measurement is a key focus for industrial applications. Ultrasonic thickness gauges are favored in the industrial testing field due to their non-destructive nature and high precision. However, selecting the right ultrasonic thickness gauge can be challenging. It requires not only an understanding of the different features and functions of various gauges, but also a clear knowledge of your own measurement needs. Only then can you select a gauge that offers accurate measurements, easy operation, and the best cost-performance ratio.

By now, you should have a solid understanding of how to select an ultrasonic thickness gauge. If you have any further questions, please feel free to contact us for professional guidance and support.

Get in Touch

Please let us know your requirements and we will be in contact with you shortly!

- Color Measurement of Packaging

- Paint Thickness Gauge Test Waterproof Coating Thickness

- Greenhouse Film Spectrum Transmission Meter

- Visible Light Transmittance Meter for Testing Matte Cell Phone Film

- Difference between UV Integrator and UV Energy Meter

- How to Use Infrared Power Meter and Ultraviolet Power Meter