Linshang Ultrasonic Thickness Gauge Selection and FAQ

Linshang ultrasonic thickness gauge adopts the latest high-performance and low-power consumption microprocessor technology, based on ultrasonic measurement principle which can measure the thickness of metal, plastic, glass and other materials. It can measure the thickness of all kinds of pipes and pressure vessels in production equipment, monitor thinning degree after corrosion in use, and also can accurately measure various plates and processed parts. There are LS211/LS212/LS213/LS215/LS216 at present. The following will introduce the price, product parameters and characteristics of the above several ultrasonic thickness gauges.

LS211 tests large thickness steel

LS213 tests steel pipes

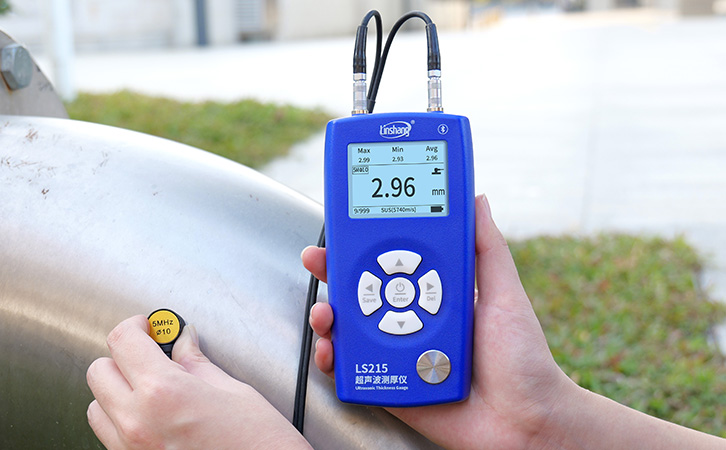

LS215 tests glass

LS216 tests metal

Parameters

| Model | LS211 | LS212 | LS213 | LS215 | LS216 |

|---|---|---|---|---|---|

| Measuring Range | 0.8-600mm(45#steel) | 0.8-350mm(45#steel) | 1-320mm(45#steel) | 13-5500μm (epoxy coating) 300-14800μm (45# steel) |

|

| Resolution | 0.8-10mm: 0.001mm 10-100mm: 0.01mm 100-600mm: 0.1mm |

0.8-10mm: 0.001mm 10-100mm: 0.01mm 100-350mm: 0.1mm |

0.8-100mm: 0.01mm 100-350mm: 0.1mm |

1-100mm:0.01mm 100-320mm:0.1mm |

1μm |

| Accuracy H is the standard value |

0.8-10mm: ±0.05mm 10-600mm: ±0.5%H |

0.8-10mm: ±0.05mm 10-350mm: ±0.5%H |

0.8-10mm: ±0.05mm 10-350mm: ±0.5%H |

1-10mm: ±0.05mm 100-320mm: ±0.5%H |

≤±(3%H+3μm) |

| Probe Specification | 5MHz φ10 dual-crystal probe | ||||

| Sound Velocity Range | 1000~19999m/s | 1000~9999m/s | |||

| Display | 240 * 160 dot matrix LCD | 800 * 480 dot matrix IPS color screen | |||

| Unit | mm/inch | μm/mil | |||

| Host Size | 142*72*28 mm | 141.7*91.1*22.6 mm | |||

| Weight | About 230g | 475g | |||

Features

The instrument can measure material thickness up to 600mm, meeting the measurement needs of most users.

The LS216 can simultaneously measure the thickness of multi-layer coatings and the base material itself, offering a wide range of applications.

The instrument has high testing accuracy, up to ±0.05mm, ensuring compliance with national authority metrology standards.

The instrument features an LCD high-definition display screen, with clear readings even in backlit environments. The LS216 comes with a color touch screen, making operation even easier.

The LS216 provides real-time waveform display during measurements, allowing users to intuitively view echo data at different locations, aiding in quick analysis.

Automatically selects the appropriate gain based on material type and thickness, ensuring optimal measurement results.

Features QC judgment function, determining whether incoming materials are qualified based on the set upper and lower limits, enabling quick material inspection.

Automatically calculates the maximum, minimum, and average values of the last 9 measurements.

The instrument allows adjustment of sound velocity in 3 ways: selecting sound velocity for known materials, setting sound velocity for known thickness, or manually adjusting the sound velocity.

Can be connected to a mobile app or PC software for easy data storage and sharing.

Comfortable grip, easy operation, and ergonomic design.

Introduction

Large range, high resolution of 0.001mm

Small range, high resolution of 0.001mm

Small range, economical version, resolution of 0.01mm

Small range, economical version, resolution of 0.01mm

Resolution: 1μm

Frequently Asked Questions

-

Does the instrument need to be calibrated before each use?

It is not necessary, the instrument is already calibrated at the factory, so there is no need for frequent calibration.

-

What kind of materials can your instruments test?

Ultrasonic thickness gauge adopting pulse reflection ultrasonic measurement principle, all can make the ultrasonic wave at a constant speed in its internal propagation of various materials can be measured using this principle. The measured material is various, suitable for testing the thickness of various metals, plastics, ceramics, glass, glass fiber.

-

What is the reason for the inaccuracy of the instrument test?

The sound velocity is incorrect, if you can set the correct sound velocity by selecting the correct material, manually inputting sound velocity, and inverse measurement of the sound velocity through the material.

There are dust, dirt, paint and other coverings on the surface of the measured object.

The surface of the object to be measured is too rough or uneven, which will also affect the measurement accuracy.

The ambient temperature during the test exceeds the working temperature range of the instrument.

-

Can the instrument measure curved surface materials?

Yes, the instrument can measure curved surface materials when paired with a micro-diameter probe (7MHz PT-06). The probe's minimum measurement area is φ6mm, and materials larger than this size can be measured.

-

What are the differences between your ultrasonic thickness gauges?

The LS211 has a measurement range of 0.8-600mm, with a resolution of 0.001mm.

The LS212 has a measurement range of 0.8-350mm, with a resolution of 0.001mm.

The LS213 has a measurement range of 0.8-350mm, with a resolution of 0.01mm.

The LS215 has a measurement range of 1.0-320mm, with a resolution of 0.01mm.

These four models measure the thickness of materials such as metals, glass, ceramics, plastics, and other materials capable of transmitting ultrasonic waves.

The LS216 has a measurement range of 13-5500µm (epoxy resin coating), 300-14800µm (45# steel), with a resolution of 1μm, and measures the thickness of multi-layer coatings as well as the base material itself.

-

What should I do when the coupling agent is used up?

The couplant is a universal product and can be purchased online.

-

Are you a manufacturer or trade company?

We are factory , we have engineers for researching & designing and workers for produce and operate etc, we could support you one-stop products and service.

Your product information request

- LS201 Glass Thickness Gauge for Laminated Glass Thickness

- Study on Coating Thickness with Coating Thickness Gauge

- How to Restore the Car Paint Surface Gloss?

- Measuring the Transmittance of the Watch Dial with Optical Density Meter

- Linshang High Precision Glass Check Thickness Meter For Sales

- Online Monitoring of UVC Meter