Liquid Colorimeter: Accurate Liquid Color Measurement

In color measurement and control, color detection for solid surfaces is already well-established. However, when testing transparent or semi-transparent liquids like edible oils, beverages, or pharmaceutical solutions, traditional reflection-based colorimeters often fail to deliver accurate color readings for such liquids. This poses challenges for industries such as food, pharmaceuticals, and chemicals. In such cases, a liquid colorimeter designed for transparent and semi-transparent materials is needed for precise measurement.

Classification and Working Principles of Liquid Colorimeters

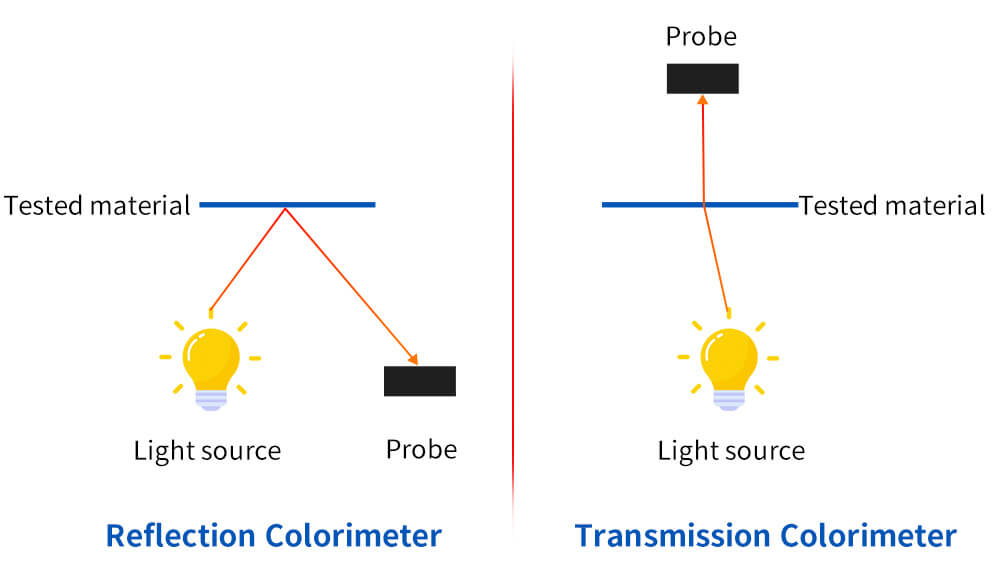

Colorimeters are mainly divided into reflection and transmission types based on their working principles.

-

Reflection Colorimeter

The instrument contains a standard white light source defined by the International Commission on Illumination (CIE). The light is projected onto the sample at a fixed angle. When it hits the surface, part of the light is reflected, carrying information about the sample’s surface color — specifically, which wavelengths are absorbed and which are reflected. The reflected light is then captured by the detector inside the instrument. The data is analyzed to calculate tristimulus values (X, Y, Z), which are then converted into Lab and other color data.

Reflection colorimeters measure surface color only, relying entirely on reflected light. They are suitable for opaque materials and some non-transparent liquids, such as paints and coatings.

-

Transmission Liquid Colorimeter

A transmission liquid colorimeter emits light from a built-in standard light source that passes through the transparent or semi-transparent sample. During this process, the material selectively absorbs certain wavelengths of light. The remaining light exits from the other side of the sample and is captured by the detector. The sensor analyzes the transmitted light and calculates the tristimulus values (X, Y, Z) to generate Lab and other color data.

Transmission liquid colorimeters are specifically designed for clear or translucent liquids. Most liquid color measurements, such as beverages, edible oils, pharmaceutical solutions, and wastewater, require transmission colorimeters.

Industries Suitable for Liquid Colorimeters

Liquid colorimeters are extensively used across modern industries. They help maintain strict quality control, accurate grading, and consistent color in liquid products.

1. Food and Drink Industry

Color is an important factor in evaluating the freshness, purity, and visual appeal of food and drink. A liquid colorimeter can measure the color and color difference of edible oils, such as peanut oil and olive oil, helping manufacturers adjust production processes based on color variations. Liquid colorimeters can also measure the color of juices to assess concentration and freshness, as well as the color of alcoholic drinks, soy sauce, vinegar, and other condiments to evaluate brewing levels and ensure product consistency.

2. Pharmaceutical Industry

Color consistency is critical for pharmaceuticals, as it affects brand recognition and patient trust. Liquid colorimeters are used to measure the color of liquid preparations such as oral solutions, injections, and syrups to ensure they meet pharmacopeia standards (e.g., USP/EP). During production, monitoring the color changes of reaction liquids with a liquid colorimeter can indirectly indicate reaction progress or purity. Additionally, the color of a liquid is a key indicator for detecting contamination, oxidation, or degradation of the product.

3. Dye Testing

A liquid colorimeter accurately measures the color of varnishes, transparent coatings, dyes, and pigment solutions. It helps companies evaluate tinting strength. With a spectral liquid colorimeter, issues like metamerism can be avoided, ensuring consistent color in every batch of dyes and coatings for stable and uniform results that meet customer requirements.

4. Chemical Industry

In the chemical industry, a liquid colorimeter is essential for quality control. It measures the color of solvents, acids, bases, and polymer solutions to evaluate their purity and grade. A spectral liquid colorimeter captures the full transmission spectrum curve, delivering precise and quantifiable data to ensure products meet strict quality standards. A liquid colorimeter can also measure the color of liquid detergents, helping maintain consistent quality, batch-to-batch uniformity, and brand recognition.

Challenges in Liquid Color Measurement

Liquid color measurement is more complex than measuring solids. This is mainly because the physical properties of liquids and environmental factors can easily affect the accuracy of color measurement.

-

Liquid Transparency

Transparent or semi-transparent liquids are easily affected by background color, container material, or even their own refractive index during measurement. Different liquids have different transmittance and refractive indices. Those containing particles or suspended matter are more prone to light scattering, which impacts the results. Using a liquid colorimeter with high-transmittance cuvettes can effectively eliminate background and container interference, accurately showing the liquid’s true color.

-

External Light Interference

Liquid color measurement is highly affected by ambient light. Under different lighting conditions in labs or production lines, manual color judgment can lead to large errors. A liquid colorimeter with a built-in stable light source standardizes the testing light, eliminating interference from external lighting. This ensures consistent color measurement across different locations and improves the reliability and repeatability of the results.

-

Metamerism

Liquid colors often show metamerism, meaning they look one color under one light source and a different color under another. This can create serious challenges in production and color control, increasing the risk of color inconsistencies. The issue is especially critical for inks and dye solutions, where slight color differences can greatly affect product quality. A spectral liquid colorimeter solves this problem by measuring the liquid’s spectral transmittance curve, accurately detecting metamerism without manual comparison under multiple light sources, greatly improving both efficiency and accuracy.

-

Limitations of Measurement Methods

Traditional reflection colorimeters cannot accurately measure liquid colors, while transmission liquid colorimeters are often costly. For businesses, choosing a liquid colorimeter that meets measurement needs while offering high cost-effectiveness is key to reducing testing costs and improving production efficiency.

Standards for Liquid Colorimeter

CIE 15:2004 Colorimetry

USP: Color—Instrumental Measurement

ISO/CIE 11664-4:2019 Colorimetry - Part 4: CIE 1976 L*a*b* Colour space

ISO 7724-1~-3:1984 Paints and varnishes – Colorimetry

ASTM D1209:2019 Standard Test Method for Color of Clear Liquids (Platinum-Cobalt Scale)

ISO 6271:2004 Clear liquids — Estimation of colour by the platinum-cobalt scale

ASTM E1347-2006(2015) Standard Test Method for Color and Color-Difference Measurement by Tristimulus Colorimetry

ASTM E308-2022 Standard Practice for Computing the Colors of Objects by Using the CIE System

ASTM E1164-2023 Standard Practice for Obtaining Spectrometric Data for Object-Color Evaluation

How to Use a Liquid Colorimeter

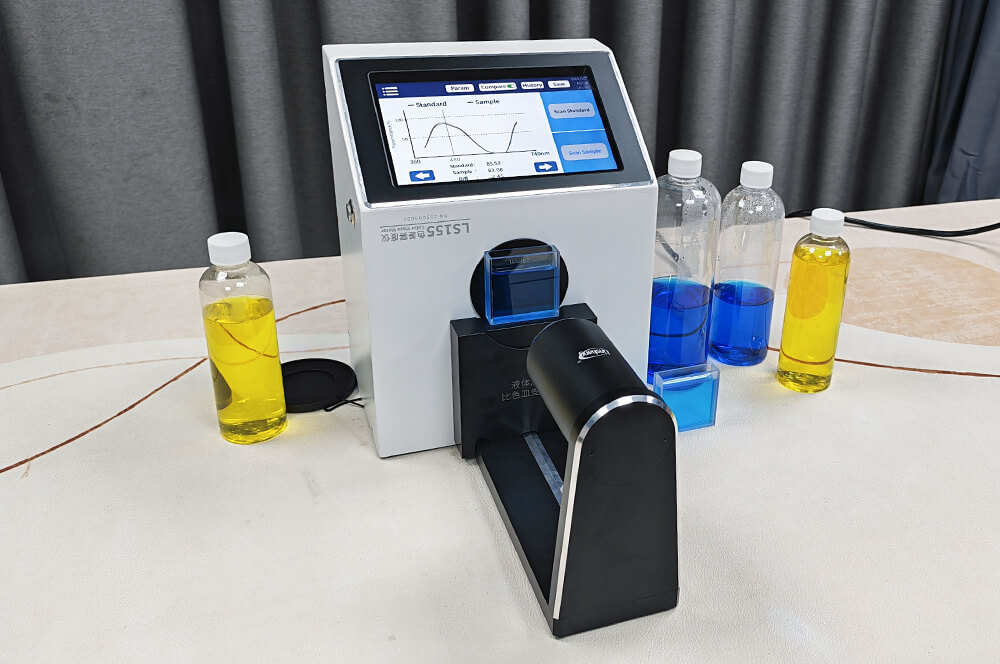

A liquid colorimeter offers a reliable, objective way to quantify liquid color with precision. It reduces human error, handles complex conditions, eliminates environmental interference, and supports precise digital color management and communication. So, how do you measure liquid color? Here’s an example using the Linshang LS155 Color Haze Meter.

How to use a liquid colorimeter

Advantages of the Linshang Color Haze Meter

Linshang is a high-tech manufacturer specializing in the R&D and production of colorimeters. Its independently developed products hold multiple national patents and are trusted by customers worldwide. The LS155 Color Haze Meter, designed for clear or translucent materials, delivers excellent performance and powerful functions in liquid color measurement.

Supports both ASTM and ISO standards, with three standard light sources (CIE-A, CIE-C, and CIE-D65) and two apertures (5mm and 14mm) to flexibly meet different testing needs.

Measures multiple parameters, including color difference, transmittance, haze, and platinum-cobalt color, to assess liquid purity and color consistency.

Built-in professional spectral sensor for transmittance spectrum measurement, showing transmission data across 400–700 nm to fully evaluate liquid color and detect metamerism.

7-inch touch screen with a user-friendly interface, enabling color difference measurement in just two steps — simple and efficient operation.

Unique signal processing technology ensures measurement results are not affected by external light interference.

Provides high accuracy and repeatability, with results verifiable by the National Institute of Metrology for reliable data.

Comes with professional PC software for exporting data and printing test reports, making color management and analysis convenient.

Offers excellent cost-effectiveness, with pricing lower than most liquid colorimeters on the market, while providing more comprehensive functions such as color difference, haze, platinum-cobalt color, and spectral curve measurements.

Linshang has a professional team of over 100 members, offering comprehensive pre-sales and after-sales support. There is no MOQ requirement for the Linshang Color Haze Meter. Whether you need just one unit or a bulk order, Linshang ensures on-time delivery. Customization services are also available, including personalized appearance and logo design.

The Linshang LS155 Color and Haze Meter is a high-precision instrument designed specifically for transparent and semi-transparent liquids. As a liquid colorimeter, it is ideal for testing the color of edible oils, beverages, pharmaceuticals, chemicals, dyes, and more. The liquid colorimeter accurately detects even slight color differences, helping businesses maintain strict quality control, ensure consistent product color, and quickly classify products, making it a valuable tool for improving both production efficiency and product quality.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.