What Is a Light Meter?

A light meter, also called a lux meter, is a device used to measure light intensity, usually expressed in Lux (Lx). Dim lighting environment can reduce visual comfort, while an overly bright environment may cause dizziness, affect work efficiency, and even harm health. Therefore, adequate and comfortable lighting is essential for both life and work, and a light meter is the key tool to achieve this goal. So, how can you choose the right light meter? First, determine the type of light source you want to measure, as different light sources have different performance requirements for light meters. Second, understand the working principles and features of various types of light meters to assess whether they meet your testing needs. Next, learn how to use a light meter and become familiar with the meaning and application value of each measurement parameter. Finally, choose a trustworthy light meter manufacturer to ensure both product quality and measurement accuracy.

What Light Sources Do Light Meters Measure?

In our daily work and life, we often encounter different types of light sources, from natural sunlight to artificial lighting such as incandescent lamps and LED lights. But when it comes to evaluating their brightness, color quality, or spectral properties, you may wonder: which light sources can actually be measured with a light meter?

-

LED Light Sources

White LED: A regular light meter can be used for measurement. However, since white LEDs typically use a blue light chip combined with phosphor, they may have insufficient red light and an uneven spectral distribution. To ensure accuracy, it is recommended to use a high-quality light meter with V(λ) correction, as low-end meters may produce errors of ±10% or more.

Colored LED: Standard lux meters are calibrated for white light, so measurements of monochromatic or colored LEDs may have significant deviations. A spectral light meter should be used instead.

-

Traditional Lamps (Incandescent, Halogen)

These have a continuous spectrum covering the visible range, closely matching the human visual response. A standard lux meter can measure them accurately.

-

Natural Light (Sunlight, Skylight)

Light intensity changes rapidly, requiring a fast-response sensor. Under strong midday sunlight, avoid sensor saturation and use a lux meter with a wide measurement range.

-

Special-Purpose Light Sources

Plant Growth Lamps: Require measurement of parameters such as PPFD/YPFD. A spectral lux meter is necessary; standard lux meters are not suitable.

What is a Light Meter Used for?

Light Meter Applications cover a wide range of fields, making them an essential tool in many industries. Below are some of the most common applications of light meters.

-

Lighting Production and Quality Control

In the production of lamps such as desk lamps, floor lamps, and LED fixtures, light meters are used to accurately measure light intensity, ensuring products meet international standards (e.g., IES LM-79 for photometric testing of solid-state lighting products and ANSI/IES RP-16-17 for lighting terms and definitions). They are also used to check brightness consistency across different batches and models, helping optimize quality control processes.

-

Indoor Lighting Design and Inspection

In indoor lighting projects for offices, schools, shopping malls, hospitals, and other spaces, light meters are used during final inspection to verify that actual lighting levels meet design requirements (e.g., EN 12464-1:2021 for workplace lighting and CIE S 008/E:2001 for visual comfort guidelines). This ensures both visual comfort and functional needs are met.

-

Industrial and Safety Lighting Monitoring

In factories, warehouses, underground parking lots, and similar locations, light meters are used for regular checks to ensure lighting meets occupational safety standards (e.g., OSHA 1910.305(b)(3) for workplace lighting in the U.S. and ISO 8995-1:2002 for workplace lighting). This helps maintain safe operations and work efficiency.

-

Agriculture and Plant Lighting Management

In modern agriculture (e.g., greenhouses, vertical farms), light meters—often combined with spectrometers—are used to monitor plant grow lights, ensuring they meet plant lighting requirements (e.g., ASABE S640 standard for measuring horticultural lighting). This supports precise supplemental lighting to boost crop yield and quality.

-

Public Facilities and Roadway Lighting Assessment

In roads, tunnels, stadiums, airports, and other public lighting systems, light meters help evaluate lighting quality to ensure compliance with international standards (e.g., CIE 115:2010 for road lighting and EN 13201:2015 for roadway lighting performance). This ensures nighttime safety and improves energy efficiency.

Note: Depending on the application, light meters of different accuracy levels can be selected, ideally those meeting international standards such as ISO/CIE 19476:2014 (performance requirements for illuminance meters).

What are the Different Types of Light Meters?

At present, the most common light meters on the market are digital light meters, analog light meters, and spectral light meters. Below is a detailed introduction to the working principles of these three types of light meters:

Digital Light Meter: Light strikes the photosensitive detector (commonly a silicon photodiode), converting the light signal into a tiny current proportional to the light intensity. The analog current signal is amplified by an operational amplifier, then converted into a digital signal through an A/D (analog-to-digital) converter. The microprocessor calculates the illuminance value (lux) and displays it on the LCD screen.

Analog Light Meter: Light strikes a photoresistor (CdS) or photodiode, changing its resistance value or generating a current. The current directly drives a mechanical pointer gauge, where the deflection angle of the pointer is proportional to the illuminance. Readings are taken from a calibrated scale. Due to its weak response to blue light, it has gradually been phased out in the LED era.

Spectral Light Meter: Light enters through the aperture into a diffraction grating or prism system, where it is dispersed into different wavelengths. The processor integrates the spectral data to calculate total illuminance, while also analyzing parameters such as correlated color temperature (CCT), color rendering index (CRI), and blue light hazard.

Advantages of a Spectral Light Meters

The spectral light meter offers advanced features that go far beyond basic illuminance measurement, providing users with comprehensive and accurate lighting analysis. Its main advantages include:

Multi-parameter measurement: Capable of measuring illuminance, color temperature, flicker frequency, UV index, color tolerance, color rendering index, PPFD, YPFD, and more simultaneously, helping customers fully evaluate lighting characteristics.

High-precision spectral sensor: Can measure spectral curves to view light intensity at different wavelengths and the distribution of the light source across various bands.

Wide measuring range: Accurately measures from extremely low to extremely high light levels, suitable for a variety of applications.

Broad application scope: Ideal for lighting design, lighting quality monitoring, plant lighting management, and more.

Suitable for special light sources: Accurately measures colored, monochromatic, or mixed-spectrum light sources that are difficult for traditional silicon-based lux meters to handle.

How to Use a Light Meter?/How to Read a Light Meter?

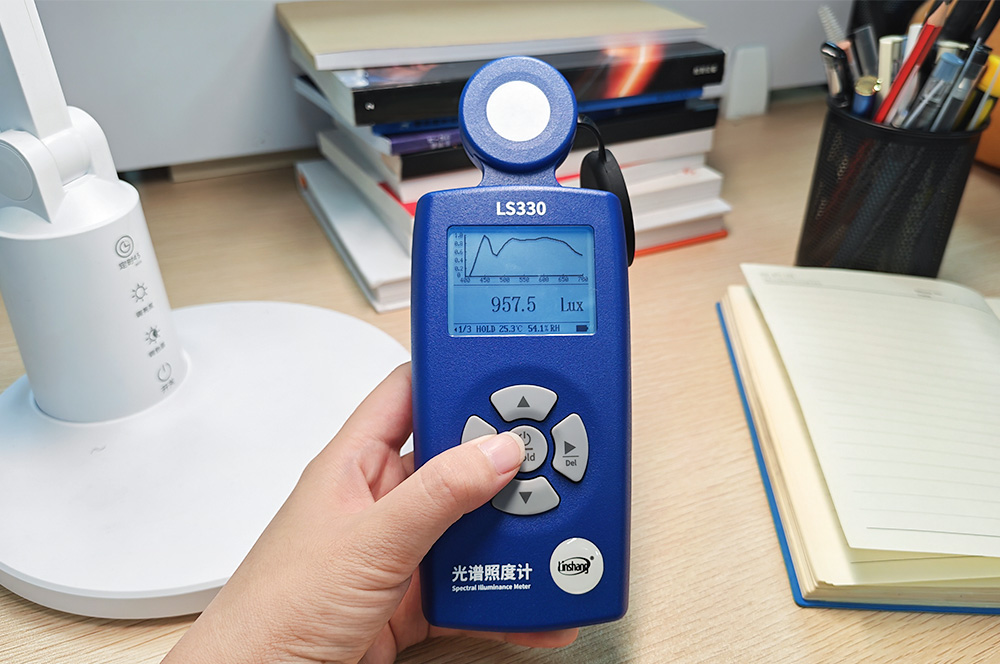

After understanding the basic information about light meters, a new question arises: How do you use a light meter? The following will introduce the usage of a light meter using the Linshang LS330 spectral light meter as an example.

1.Determining the Measurement Position

Choose the light meter’s measurement position according to the actual application scenario.

Workplace lighting: Place the light meter horizontally on the work surface to simulate the position where the human eye receives light.

Road/ground lighting: Place the device directly on the ground to ensure the measurement height matches the real usage environment.

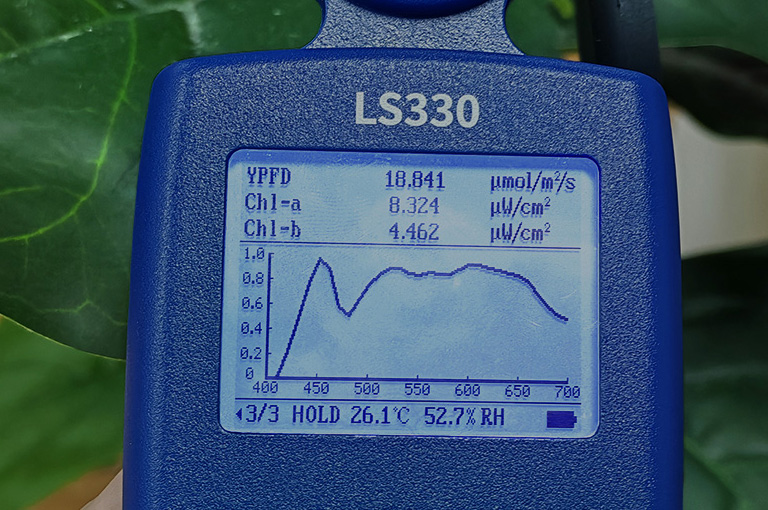

Plant growth lighting: Position the sensor at the height of the plant canopy, facing the light source, to accurately reflect the light received by the plants.

2. Measurement Data Interpretation

Once the light source is stable, the screen may display the following parameters:

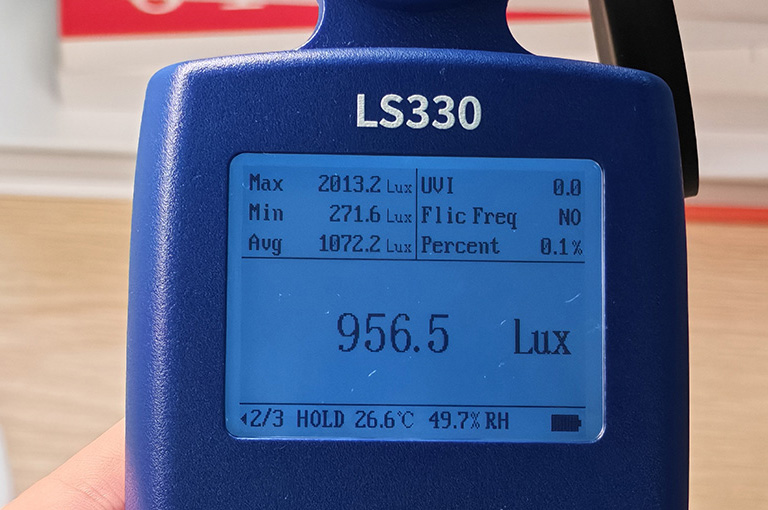

Lux Value: The amount of luminous flux received per unit area, measured in lux (lx). Used to determine if the lighting level meets required standards.

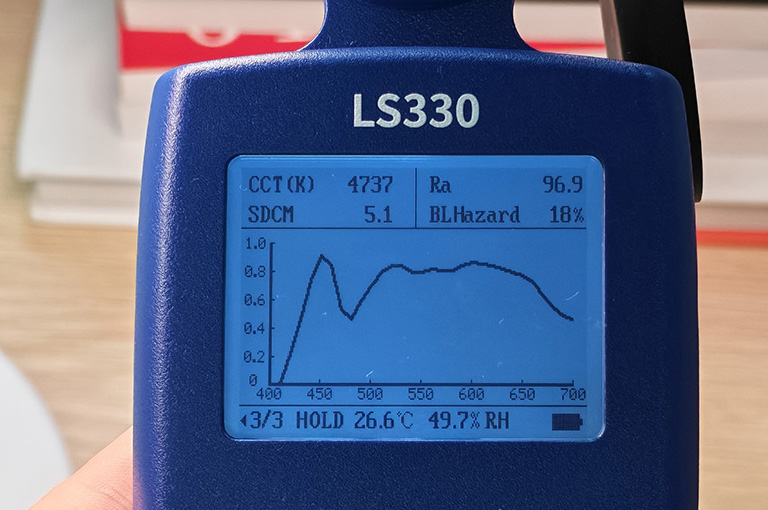

Spectral Curve: Radiation distribution of the light source across different wavelengths. Used to analyze color composition, color rendering, blue light proportion, and other characteristics.

UV Index: Indicates the strength of ultraviolet radiation. Used to assess potential harm to humans or materials.

Flicker Frequency: The rate at which light brightness changes, in Hz. Detects flicker to prevent visual fatigue or discomfort.

Flicker Depth / Percent: The amplitude of brightness change, shown as a percentage. Lower values indicate less flicker.

CCT (Correlated Color Temperature): The color temperature of the light source, in kelvins (K). Indicates whether the light appears warm, neutral, or cool.

SDCM (Standard Deviation of Color Matching): Measures color consistency of the light source. Smaller values mean less color variation.

Ra (Color Rendering Index): The ability of the light source to reproduce object colors accurately (0–100). Higher Ra values indicate colors closer to natural light.

Blue Light Hazard Ratio: Measures the potential risk of blue light to human eyes. Used to assess blue light safety levels for eye protection.

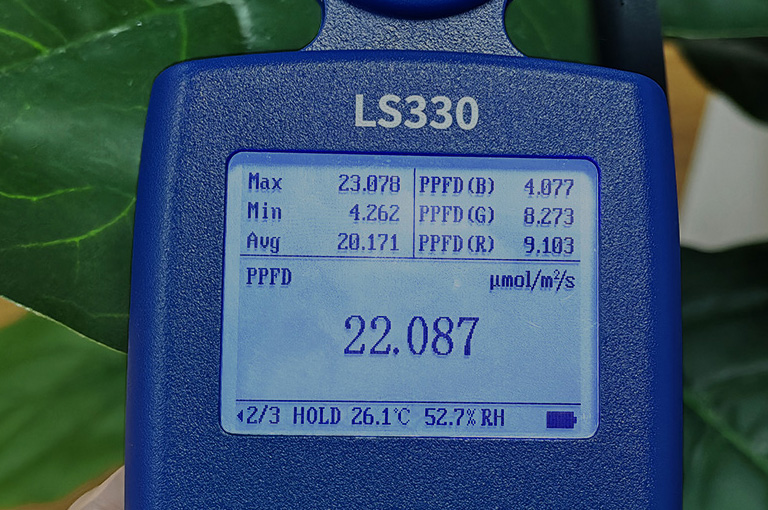

PPFD (Photosynthetic Photon Flux Density): The number of usable photons per unit area per second for plants, measured in μmol/(m²·s). Used in agriculture to evaluate effective plant growth light intensity.

YPFD (Yield Photon Flux Density): Photon flux density weighted by plant photosynthetic efficiency, providing a more accurate measure of usable light for plants.

Professional Light Meter Manufacturer

Now that you understand the basics of light meters, choosing the right manufacturer is crucial if you plan to purchase one. Selecting a professional light meter manufacturer means choosing comprehensive data measurement, accurate results, durable product quality, and reliable after-sales service. Linshang spectral light meter is a great choice. It can simultaneously measure multiple parameters, including illuminance, color temperature, flicker frequency, UV index, color tolerance, color rendering index, PPFD, and YPFD. It can also measure the spectral curve of a light source, helping customers comprehensively evaluate lighting performance. With a measuring range of up to 1,000,000 lux, it meets the needs of most measurement scenarios. The results from the Linshang spectral light meter can be verified by metrology institutes and comply with international standards. It can store multiple sets of data and automatically calculate maximum, minimum, and average values to help assess light uniformity.

As a professional optical instrument manufacturer, Linshang Technology has been committed to providing high-precision and highly reliable measurement solutions to customers worldwide since its establishment in 2008. With over 17 years of experience in optics, Linshang has become one of the leading manufacturers in the optical measurement industry. It has a strong R&D team to ensure continuous innovation and strict quality control, delivering high-quality products at highly competitive prices. Linshang has developed multiple series of high-precision measuring devices, and its self-developed products have obtained more than 100 patents and related certifications. To date, the company has served over 100,000 customers in more than 100 countries, and the Linshang brand enjoys wide recognition in the global instrument industry.

Linshang Technology promises:

Strictly control product quality and provide instruments with precise measurement capability

No minimum order quantity(MOQ) — even a single unit can be shipped

More competitive pricing advantages

Professional pre-sales technical consultation and comprehensive after-sales service

In addition, Linshang is seeking agents and distributors for its light meter products worldwide. Whether you need to represent Linshang’s standard products or require OEM customization, Linshang Technology can offer flexible cooperation models to achieve mutual benefit and win-win results.

As a key tool for measuring light intensity, a light meter plays an important role in many fields—from ensuring quality in lighting manufacturing to optimizing workplace illumination, as well as industrial safety monitoring, agricultural plant lighting management, and public lighting system evaluation. Scientific and accurate data from light meters help avoid the errors that can occur when judging light intensity with the human eye. At the same time, the objective data provided by a light meter makes it easier to establish unified testing standards, offering a solid scientific basis for creating healthy, comfortable, and efficient lighting environments. Whether you are a lighting designer, a quality inspector, or anyone who needs to evaluate lighting conditions, a precise and reliable light meter will be your trusted partner.

Get in Touch

Please let us know your requirements and we will be in contact with you shortly!

- Application of fabric colorimeter in fabric industry

- Ultraviolet Detector | Germicidal Lamp Intensity Test

- How to Distinguish Fireproof Paint by Glossiness Detection?

- Application of Thickness Measurement Equipment in Anti-Corrosion Industry

- Light Transmittance Meter With Diffuse Transmission Principle

- Surface Gloss Meter | How to Select Gloss Measurement Angle?