How to Use a Spectrophotometer for Plastic Color Matching

In plastic manufacturing and injection molding, color consistency is critical. Relying on visual judgment or operator experience is unreliable and often inconsistent. A spectrophotometer for plastics provides accurate, objective Lab data to measure the color of plastics. This ensures reliable plastic color measurement and eliminates subjective judgments such as “the color looks different.” The result is greater efficiency and accuracy in plastic color measurement and matching.

Why Use a Spectrophotometer for Plastics

The appearance of a product reflects the brand’s identity. In plastics, color strongly affects first impressions and purchasing decisions. Consistent color measurement for plastics also strengthens brand recognition—when consumers see a familiar shade, they associate it directly with the brand. Inconsistent colors across batches may raise doubts about quality control and damage the brand image. This is why it is essential to measure the color of plastics and ensure color consistency.

Relying on the human eye to judge color is highly subjective. Factors such as lighting conditions, viewing angle, background, and individual perception often lead to inaccurate results. In contrast, plastic color measurement using a colorimeter or spectrophotometer provides reliable and objective data, reducing uncertainty in color measurement for plastics.

Advantages of Using a Spectrophotometer for Plastics

Unaffected by environment: A spectrophotometer for plastics has a built-in standard light source and fixed viewing angle (10°). This ensures every test is performed under the same conditions, eliminating the influence of lighting, angle, or background. The result is stable and reliable color measurement for plastics.

Quantified data: The device provides accurate Lab values that convert subjective perception into objective numbers. With this data, companies can establish a unified color standard and avoid communication problems where the color described by a client does not match the final product.

Color matching support: When measuring the color of plastics, the spectrophotometer shows the exact color bias—whether a sample looks more red, green, yellow, or blue. This guides technicians to adjust formulations quickly and precisely, improving production efficiency.

Metamerism detection: Unlike basic colorimeters, a spectrophotometer can measure the reflectance curve of plastics. This solves the metamerism issue—when a sample looks the same under one light source but different under another.

In modern plastic and injection molding industries, the spectrophotometer has replaced visual judgment and become an essential tool for plastic color measurement and quality control.

Causes of Color Difference in Plastics

Color difference in plastics is a common issue. The main reasons for plastic color differences include:

-

Masterbatch or pigment variations

Different batches of masterbatch or pigments may show slight differences in color or dispersion, which leads to inconsistent plastic colors. To measure the color of plastics such as powders or small granules, samples must be placed in a cuvette and tested with a large-aperture spectrophotometer for plastics.

-

Resin differences

Base resins may vary slightly in whiteness or yellowness between batches, which affects the final plastic color. A spectrophotometer can measure whiteness and yellowness values to help select the most suitable resin.

-

Additives

The inherent color of antioxidants, plasticizers, flame retardants, and fillers (such as glass fiber and calcium carbonate), as well as content variations between different batches, can also alter the color of plastics.

-

Injection molding process

Changes in molding time, temperature, or pressure affect gloss, depth, and uniformity of color. This is a key factor in plastic color measurement.

-

Equipment factors

Aging injection molding machines, worn screws or barrels, or reduced dispersing ability can cause uneven colors. Incomplete cleaning may also leave oil stains or leftover material that mixes with new resin, creating color differences.

-

Human factors

Inconsistent operating methods, inaccurate pigment weighing, non-standard formulations, or improper color measurement for plastics can all result in noticeable color variation.

How to Measure the Color of Plastics

When a customer brings in a plastic sample, how can you accurately measure its color and quickly find the closest color chart code?

What is the Color Code for Plastic

A plastic color chart is a standardized color system that assigns codes to specific colors. These codes make it easier to choose, communicate, and reproduce colors. Instead of vague descriptions, a color code ensures accuracy and consistency in plastic color measurement. Commonly used color systems include:

Pantone – the most widely used color system worldwide

RAL – popular across Europe

NCS – mainly used in Northern and European countries

Custom plastic color charts developed by individual companies

Before starting production, it is important to confirm with the customer whether a standard color code should be used.

How to Use a Spectrophotometer for Color Matching

With a spectrophotometer for plastics, you can measure the color of plastics accurately and match it to the correct color code within seconds, eliminating the need for manual comparison. So, how can a spectrophotometer for plastics quickly find the closest international color chart code or a factory’s own chart? Let’s take the Linshang LS173 as an example.

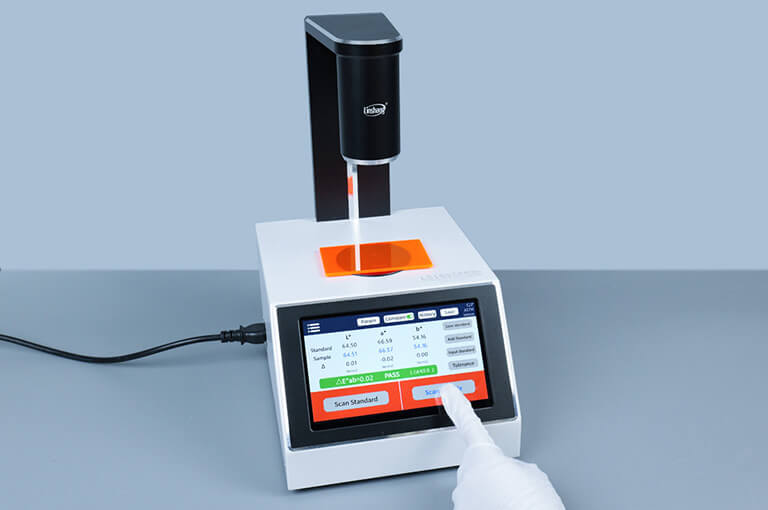

How to use a LS173 spectrophotometer for color matching

How Does a Spectrophotometer Help with Plastic Color Matching

To use a spectrophotometer for plastics in color matching, it is important to first understand the principles of color mixing and the meaning of Lab values.

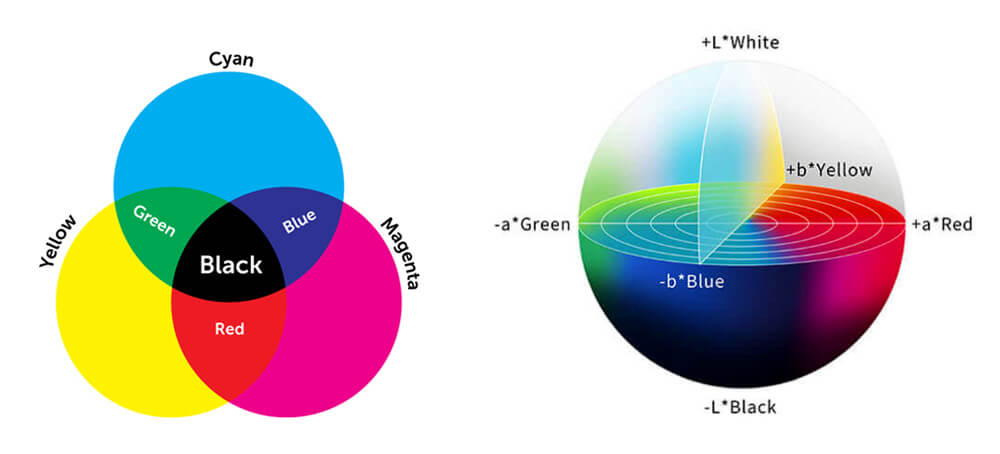

Principles of Color Mixing

In optics, red, green, and blue follow the additive mixing principle: the more colors overlap, the brighter the result. This applies to light sources.

In plastics, subtractive mixing is used with cyan, magenta, and yellow. The more pigments are added, the darker the color becomes. Since plastics do not emit light, color adjustment is achieved by changing pigment or masterbatch ratios to alter light absorption and reflection.

Cyan pigment absorbs red and reflects green and blue.

Magenta pigment absorbs green and reflects red and blue.

Yellow pigment absorbs blue and reflects red and green.

The color measurement for plastics with a spectrophotometer usually relies on the Lab color space.

L* – lightness. A higher L means lighter color; a lower L means darker color.

a* – red/green axis. Positive = red, negative = green.

b* – yellow/blue axis. Positive = yellow, negative = blue.

For example, a slightly low measured L value means the plastic looks slightly dark. Adding white pigment (titanium dioxide) can correct it.

How to Use a Spectrophotometer to Assist Plastic Color Mixing

When a plastic sample is produced, a spectrophotometer for plastics can be used to check the color difference between the sample and the selected color chart code or standard reference. If the result does not meet the requirement, the measured color deviation indication helps guide adjustments to the pigment or masterbatch ratio. Taking the Linshang LS173 as an example.

How to use LS173 spectrophotometer to assist plastic color mixing

Color Standards for Plastics and Injection Molded Parts

ISO 7724-2 Paints and varnishes - Colorimetry - Part 2: Colour measurement

ISO/CIE 11664-4:2019 Colorimetry - Part 4: CIE 1976 L*a*b* Colour space

ISO 4582:2017 Plastics - Determination of changes in colour and variations in properties after exposure to glass-filtered solar radiation, natural weathering or laboratory radiation sources

ASTM E308 Standard Practice for Computing the Colors of Objects by Using the CIE System

ASTM E1164 Standard Practice for Obtaining Spectrometric Data for Object-Color Evaluation

ASTM D2244 Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

ASTM D6290 Standard Guide for Measurement of Color, Appearance, and Translucence of Plastic Materials

DIN 6174 Farbmetrische Bestimmung von Farbunterschieden bei Körperfarben nach der CIE-Lab-Formel

JIS Z 8722 Methods of color measurement — Reflecting and transmitting objects

JIS K 7105 Testing method for color of plastics

Why Choose Linshang Spectrophotometers for Plastics

Founded in 2008, Linshang Technology follows the principle of “Quality, Innovation, Focus, and Integrity.” The company independently develops, manufactures, and sells a wide range of testing instruments, offering customers high-quality and cost-effective solutions. As a professional manufacturer of color measurement instruments, Linshang provides a complete range of products, from portable handheld colorimeters to high-precision spectrophotometers for plastics. Whether testing opaque plastics, transparent plastics, or masterbatch and pigment powders, Linshang delivers professional instruments to meet different needs of the plastic industry.

Among the colorimeters and spectrophotometers for plastics, Linshang LS173 spectrophotometer has significant advantages in measuring the color of opaque plastics.

Uses the international D/8° optical geometry, ideal for plastic color measurement.

Equipped with a 3.5-inch touchscreen for quick operation: one click to measure, two clicks for color comparison, and automatic pass/fail judgment.

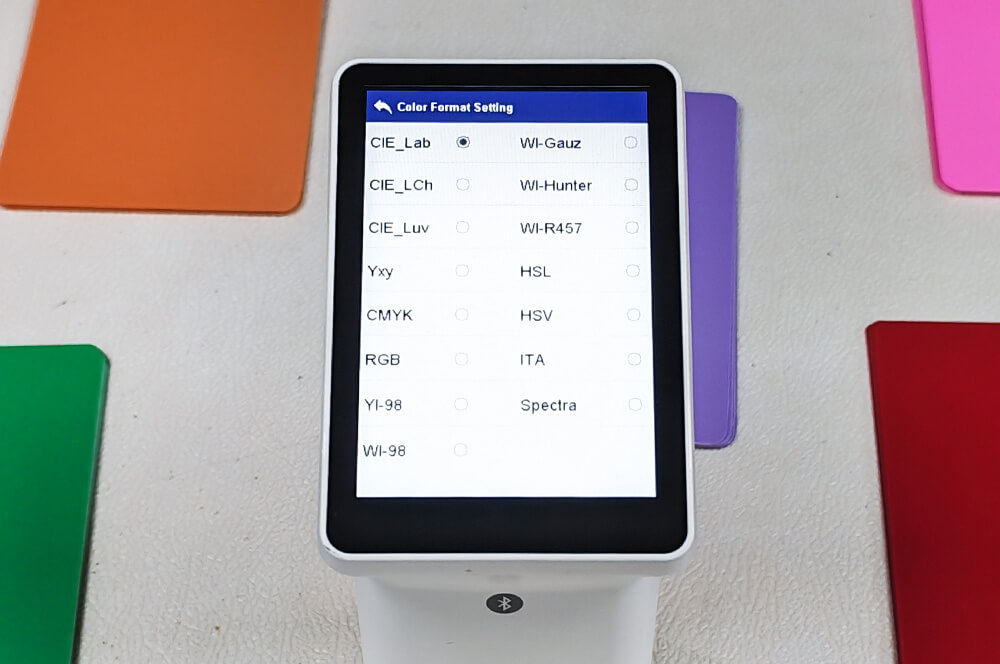

Supports multiple parameters: Lab, Lch, CMYK, whiteness, yellowness, and spectral reflectance curves, allowing full analysis of plastic color.

Built-in electronic color charts for quick matching with the closest three color codes, avoiding manual searching and issues of fading physical charts.

Allows uploading of manufacturer or industry-specific color charts for efficient and convenient color management.

Displays Lab color deviation indication (e.g., Slight Black, Slight Green, Slight Yellow) to assist technicians in accurate color adjustments.

High precision with a resolution of 0.01 and repeatability of less than 0.03 ΔE, verified by accredited metrology institutes.

Connect to both mobile apps and PC software for easy data import/export, enabling unified and standardized plastic color measurement across the entire factory. Reports can also be generated and shared directly with customers.

Spectrophotometers for Different Types of Plastics

Explore full range of colorimeters and spectrophotometers in the Linshang Colorimeter Series.

Ideal for color measurement of opaque plastic samples.

Suitable for color measurement of masterbatch, powders, and similar materials.

Designed for measuring color and light transmittance.

With over 100,000 customers in more than 100 countries, Linshang has earned worldwide recognition for its reliable instruments. The company continuously invests in R&D to maintain industry-leading quality, while also providing excellent pre-sales and after-sales support.

In modern injection molding and plastic manufacturing, reliable color measurement for plastics is essential to guarantee product quality and consistency. A spectrophotometer for plastics has become a standard tool for professional color matching and quality control. With years of dedicated research and expertise, Linshang remains a trusted brand for high-quality, precise, and professional color measurement solutions.

If you would like to learn more about Linshang’s spectrophotometers and how they can improve your plastic color management, please feel free to contact us. We are ready to help you choose the right solution.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.

- How does fabric shading come about? What can fabric colorimeters do?

- How to Measure the Specific Value of Resin Gloss?

- How to Choose the Right Measurement Angle of Gloss Meter?

- LEDCure-a LED-specific EIT UV Power Puck

- Paint Thickness Gauge with Bluetooth for Secondhand Car

- Measurement Mode Switching of Digital Paint Thickness Meter