Linshang Ultrasonic Hardness Tester Launched: Achieving Portable, Non-destructive Hardness Measurement

Have you encountered any of the following issues when using traditional bench hardness testers (such as Vickers or Rockwell) to test metal materials?

1.Significant Surface Indentation Damage:When measuring high-value, precision parts or thin coatings, traditional testers can cause irreversible surface damage, affecting both appearance and subsequent use.

2.Limited Testing Environment:Bench hardness testers, such as Vickers and Rockwell, are generally bulky and require a stable work environment or laboratory setting for measurement.

3.Measurement Location Limitations:For large and complex parts, traditional hardness testers may not be able to reach all measurement points, making on-site testing difficult. Irregularly shaped or thin workpieces may also yield unstable results.

4.Complex and Time-Consuming Operation:Traditional bench hardness testers often involve complicated, time-consuming manual operations, making them unsuitable for batch testing or quick spot checks.

In contrast, the ultrasonic hardness tester effectively solves these issues. The newly launched LS256 Ultrasonic Hardness Tester from Linshang Technology utilizes the core technology of the Ultrasonic Contact Impedance (UCI) method, providing a brand-new measurement experience!

Core Advantages:

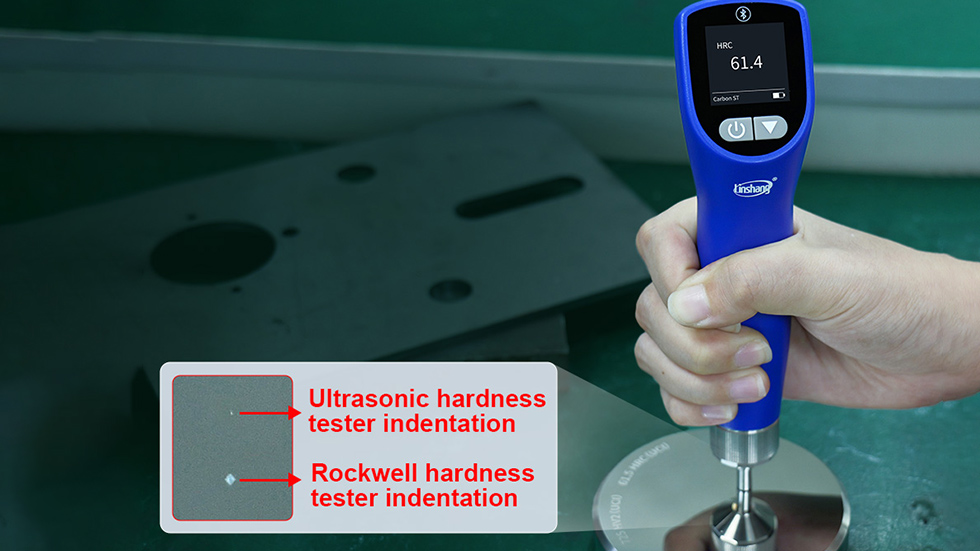

Advantage 1: Micro Indentation, Non-destructive Measurement

Using the UCI method, the indentation made during testing is extremely small, causing minimal damage to the surface of the workpiece. This method perfectly addresses the measurement challenges of thin-walled parts, high-precision components, or finished parts that are sensitive to surface damage.

Advantage 2: Accurate Measurement of Ultra-thin Workpieces

Even ultra-thin workpieces can be measured accurately (with a minimum sample weight of less than 300g and thickness under 5mm). The sample can be coupled with a lubricant and firmly supported for testing.

Ultrasonic hardness tester indentation

LS256 ultrasonic hardness tester for testing thin parts

Advantage 3: Compact and Portable, Efficient Measurement

Weighing only 245g, the LS256 is compact and easy to use. It provides immediate test results upon power-up, significantly improving testing efficiency. It is ideal for spot checks on production lines, on-site testing of workpieces, and multi-point testing of large components—allowing for precise measurement anywhere, anytime, free from the constraints of laboratory settings.

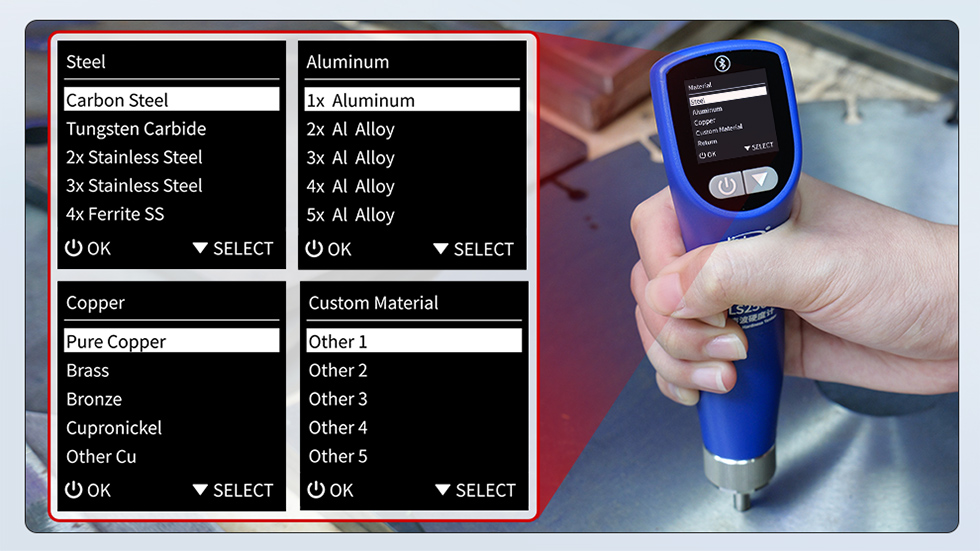

Advantage 4: Multiple Metal Materials and Hardness Scales

When measuring metals like steel, aluminum, and copper, the LS256 allows for seamless switching between different hardness scales (HV, HRC, HRB, HB, etc.), eliminating the need for manual calculations or reference tables.

LS256 Ultrasonic Hardness Tester Testing Flange

Ultrasonic Hardness Tester Material Selection

Ultrasonic Hardness Tester Hardness Scale

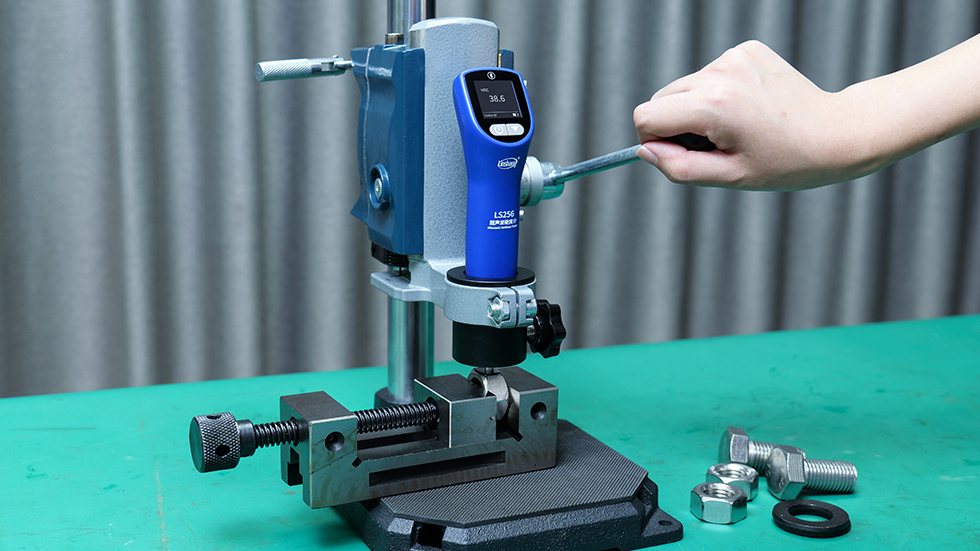

Advantage 5: Increased Precision with Optional Manual Pressure Frame

An optional manual pressure frame enhances measurement accuracy and repeatability, especially when testing irregularly shaped or small workpieces.

Advantage 6: Dual Probe Configuration, Wide Application Range

The LS256 ultrasonic hardness tester comes with a dual-probe configuration, making it flexible enough to test a variety of workpieces—whether flat materials, small parts, or complex, irregular shapes.

LS256 Ultrasonic Hardness Tester Stand

Ultrasonic Hardness Tester with Dual Probes

Other advantages of the LS256 ultrasonic hardness tester

Measurement accuracy: ±4% HV; Repeatability: ±4% HV, ensuring compliance with authoritative metrology standards.

Bluetooth connectivity for syncing with a mobile app, enabling large-scale data storage and sharing.

User calibration function: The instrument can be calibrated using standard hardness blocks, effectively eliminating system errors.

The Linshang LS256 Ultrasonic Hardness Tester is widely applicable in production sites, equipment maintenance, material quality control, and non-standard workpiece hardness testing. It provides a non-destructive, efficient, and accurate solution for quality control and productivity improvement in your operations!

- Linshang LS335 Touchscreen Spectral Illuminance Meter – Officially Launched!

- New Product: LS226 Coating Thickness Gauge

- 2023 Guangzhou International Coatings Exhibition grand opening

- New update of transmittance meter!

- 2019 IR Ink Hole Lens Transmission Meter Upgrade Again

- New Product: LS220B Paint Meter for Cars