Colorimeters for Accurate Fabric Color Measurement

In the textile industry, color control is a complex and vital process. It can even decide a product’s competitiveness and market acceptance. Color management runs through the entire supply chain, from yarn and fabric to dyeing and garment production. A single mistake in any step can affect the final result and fail to meet customer demands. Different color standards used by brands, fabric suppliers, dyeing factories, and garment manufacturers make color control even more challenging. A colorimeter or spectrophotometer provides a digital color management solution. It turns subjective color judgment into objective, consistent data, making communication faster and more accurate. It helps reduce waste and rework during color matching and adjustment, improves production efficiency, and ensures consistent color quality to meet customer requirements. Today, colorimeters and spectrophotometers have become an essential tool in the textile industry.

Colorimeters and spectrophotometers for the fabric industry

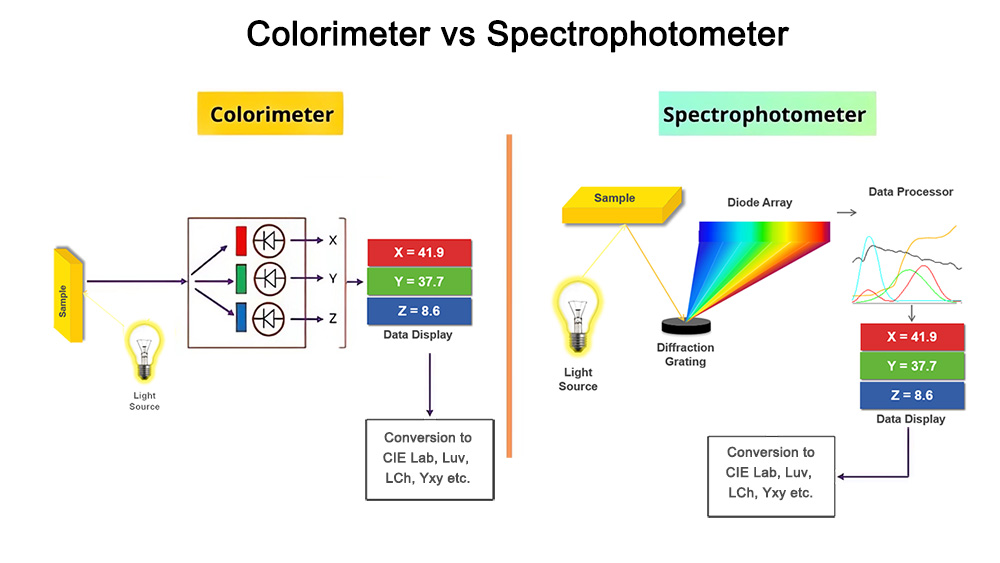

A colorimeter is a precise optical instrument for measuring color. It simulates how the human eye perceives light, turning subjective color impressions into objective, measurable data. Both regular colorimeters and spectrophotometers can measure color, but their working principles are different.

Colorimeter: It measures color using tristimulus values. The built-in light source emits white light onto the sample. The reflected light passes through red, green, and blue filters, then reaches the detector. The device directly calculates the tristimulus values X, Y, and Z, and then converts them into Lab or other color space values. A regular colorimeter has a simple measuring principle. It is compact and easy to carry.

Spectrophotometer: It measures color through spectral analysis. The built-in light source emits white light onto the sample. The reflected light is dispersed by a grating or prism according to wavelength. The detector records the intensity of light at each wavelength. After precise calculation, the device provides the reflectance spectrum data for the visible range, every 10nm. This spectrum curve is integrated to calculate the tristimulus values X, Y, and Z, which are then converted into Lab values. A spectrophotometer can measure the full visible spectrum (400nm to 700nm). Its output spectral curve helps identify metamerism, which is very useful for fabric color measurement.

Applications of colorimeters in the fabric industry

Colorimeters and spectrophotometers are key tools for color measurement and color difference control in the modern textile industry. Their applications cover the entire production chain, from yarn and greige fabric to finished garments.

1. Raw material color measurement

Colorimeters can measure the color of purchased yarns, greige fabrics, and other raw materials. They compare the results with standard colors to detect any color differences early. This helps control color quality from the start and prevents losses caused by using materials with color deviations.

2. Sample dyeing and processing

Sample dyeing is a critical step in fabric production. It provides accurate and reliable dye formulas and process parameters for mass production. At the same time, it is also one of the most challenging steps in fabric color control.

Causes of fabric color difference

Color communication errors: Everyone perceives color differently. Even when using the same fixed color card number, slight color differences may appear between different batches. Over time, color cards may also fade, causing deviations from the original color. This often results in dyed samples that do not match customer expectations.

Raw material variations: Different batches of cotton, wool, and other fibers may have different levels of whiteness and luster. Greige fabrics can also have uneven bleaching issues. These factors affect the final fabric color. To reduce color differences, the color consistency of raw materials must be ensured first. If raw material differences are unavoidable, the color-matching process should be adjusted accordingly.

Dye differences: Even with the same dye model, slight variations can exist between different production batches. Using dyes from different batches often leads to noticeable color differences.

Environmental factors: Non-standard light sources can lead to incorrect color judgments. Another issue is metamerism, where two fabrics may look identical under one light source but show significant color differences under another due to differences in their spectral reflection curves.

Human factors: Operators may not strictly follow the process requirements, or they may rely only on visual inspection without objective data. Fatigue or lack of experience can lead to inaccurate color judgments.

Using a colorimeter during sample dyeing helps set a unified color standard. This avoids differences in color perception between brands and dyeing factories, preventing the final product from failing to meet customer expectations. The device also provides objective color data. In particular, a spectrophotometer can measure the spectral curve, helping to prevent metamerism and errors caused by human visual judgment.

Fabric color-related standards

Fabric color standards usually cover multiple aspects, such as color measurement and evaluation. Below are some commonly used textile industry regulations and international standards.

ISO 105 series – Tests for color fastness, including washing, rubbing, perspiration, and light fastness.

ISO 11664 series – Colorimetry standards for color measurement and evaluation methods.

AATCC 173 – Guidelines for using spectrophotometers for color measurement.

ASTM D2244 – Methods for calculating and interpreting color differences.

CIE 15 – Guidelines on colorimetry, including XYZ and Lab color spaces.

DIN 6174 – Color difference calculation based on the CIE L*a*b* color space

GB/T 2910 – Analysis methods for color in blended fibers

GB/T 15608 – Tolerances and evaluation methods for color difference

3. Standard color storage

After sample dyeing, a colorimeter can measure the color difference between the sample and the target color. Once the customer approves the sample, its color can be saved in the colorimeter as a standard color. This makes it easy to measure and match colors in large-scale fabric production later, without worrying about the sample being lost or fading.

4. Assist in quick color matching

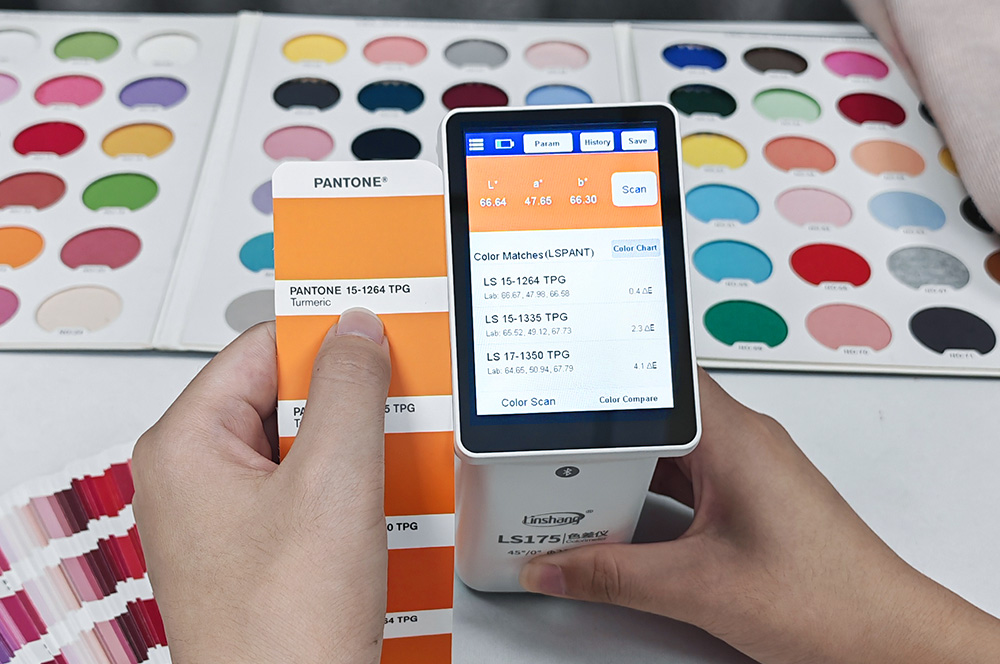

When a customer provides fabric, a colorimeter can quickly find the closest color from a color card. This saves the time of manual comparison and avoids errors caused by visual fatigue. Linshang colorimeters and spectrophotometers have a built-in TPG color card, specially for the textile industry. If a fabric manufacturer has its own color card, the colors can also be saved in the colorimeter, enabling fast and convenient color matching and color difference measurement in the future.

Choosing the right colorimeter for the fabric industry

Choosing the right colorimeter is key to obtaining accurate fabric color data. When selecting a colorimeter from the many available on the market, consider the following factors:

-

Aperture size: It is best to choose a colorimeter with a large aperture. Fabrics have textures, and small-aperture colorimeters may give very different results if the measured spot shifts slightly. Large-aperture colorimeters measure a bigger area, efficiently averaging out small-scale variations in the fabric, such as uneven thread color or texture. The larger the aperture, the closer the measurement is to what the human eye sees.

Only if you need to measure a small printed or striped area on the fabric—and the large-aperture colorimeter cannot cover it—should you choose a smaller-aperture device. This avoids nearby colors affecting the measurement.

Recommended products: 8mm aperture colorimeter, 20mm aperture spectrophotometer, 50mm aperture benchtop spectrophotometer

Accuracy: Accuracy is key when choosing a colorimeter. Only a high-precision device can ensure consistent fabric colors. High precision is especially important for mass production or custom orders with strict standards.

Ease to use: Easy operation improves work efficiency. Compared with traditional models with many buttons, a colorimeter with a simple interface and a large touchscreen is more user-friendly. It makes fabric testing smoother and is increasingly favored by manufacturers.

Electronic color cards: A colorimeter with built-in electronic color cards, such as TPG cards, saves the trouble of carrying physical cards and avoids errors from fading or damage. If a factory has its own color card system, choosing a device that supports custom card input makes color matching and measurement easier. It also helps standardize and manage in-house color data.

Brand and price: Brand and price are key factors when choosing a colorimeter. If you have a sufficient budget, you can opt for internationally renowned brands such as X-Rite. If your budget is limited but you still want a feature-rich and cost-effective device, Linshang is a great option, meeting testing needs while keeping expenses under control.

How to use a colorimeter in the fabric industry?

Traditional fabric color detection mostly relies on human eyes. This method is subjective and often leads to errors. It is also hard to know the exact color difference, which makes color adjustment challenging. In addition, finding the closest match from many color cards to the fabric provided by a customer is very difficult. The invention of colorimeters solves these problems, making color detection more scientific and accurate. So, how can we use a colorimeter correctly? Let’s take the Linshang colorimeter as an example to explain the usage:

How to use a colorimeter in the fabric industry

1. Physical color difference comparison

The colorimeter can quickly measure color differences in just two steps. Place the device on one fabric and press “Scan Standard.” Then, place it on another fabric and press “Scan Sample.” The device will display the color difference value and even tell you whether the fabric passes the quality check. Linshang colorimeters also provide color deviation indication to help with color mixing.

2. Saving standard colors

Place the colorimeter on the customer’s standard fabric and press “Scan Standard.” Then, save the color and name it in the device. Later, when testing other fabrics, you can easily call up the saved standard color and compare it without needing to bring the physical fabric.

3. Quick color matching

The device has built-in electronic color cards. For the textile industry, you can choose the TPG color card. Place the colorimeter on the fabric to measure the color, and the device will automatically show the three closest TPG color matches. This saves time and avoids the tedious process of manual color matching.

4. Custom color card library

If the factory has its own color cards, connect the device to a computer. Create a new color card library and name it. Then, measure and record each fabric color in the software. After “Write Data to Meter”, the custom color library will be available for use. During future measurements, the device can automatically match the fabric color to the closest color in this custom library.

Specialized colorimeter manufacturer

Linshang is a professional manufacturer of colorimeters and spectrophotometers, with over 17 years of experience in the optical field. Since its establishment, the company has focused on independent research, development, and production, continuously improving product quality and innovation. Linshang’s self-developed products have earned multiple national patents and have been recognized as a “National High-Tech Enterprise” for four times. The company has a team of over 100 people and its own modern factory, equipped with multiple automated and semi-automated production lines. This ensures efficient and precise manufacturing processes, delivering high-quality, cost-effective instruments along with excellent pre-sales and after-sales support.

Linshang’s colorimeter series ranges from entry-level models to high-end spectrophotometers, meeting various measurement needs. For the textile and fabric industry, Linshang developed the LS175 spectrophotometer. It features a 20mm large-aperture design, providing more accurate and stable results when measuring fabric colors. The LS175 supports multiple parameters, including Lab, Yxy, RGB, yellowness, whiteness, and spectral curves. These functions help users better analyze fabric colors and detect metamerism, making it an ideal tool for fabric color measurement.

The advent of colorimeters has solved errors common in traditional manual color comparison. Today, more and more fabric manufacturers are replacing visual inspections with colorimeters, significantly improving production efficiency and making color measurement more scientific and precise.

For fabric manufacturers, choosing a colorimeter that is stable, fully featured, and easy to use has become a crucial part of color management. Linshang colorimeters and spectrophotometers, with their comprehensive color measurement capabilities, reliable product quality, excellent cost performance, and high-quality customer service, have gradually become the preferred brand in the textile and fabric industry.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.

- Does LED Red Blue Beauty Instrument Really Work?

- UV Light Intensity Meter Maintenance and Operation

- Coating Thickness Measurement of Surface Treatment Using Paint Thickness Meter

- Coating Thickness Gauge Test Anti-corrosive Coating

- The First LS116 Light Transmittance Meter with Communication Function

- How to Choose Different UV Light Meters?