Liquid Colorimeter for Oil & Pharma Color Measuring

In the edible oil and pharmaceutical industries, color is more than appearance. It reflects quality, purity, and safety. Many pharmacopeias require color testing of liquid medicines as a core quality control step. For edible oils, factors like raw materials, processing methods, and quality levels lead to color differences. Edible oil color measurement is therefore an essential step in quality control for oil manufacturers. A liquid colorimeter delivers precise digital color data and spectral curves, replacing subjective visual checks. This ensures stable oil color and consistency across different production batches.

Applications of Liquid Colorimeter in the Edible Oil and Pharmaceutical Industries

1. Application of Liquid Colorimeter in the Edible Oil Industry

It’s normal for different types of edible oils to have different colors. However, when the oil color of the same variety varies noticeably, it often points to issues such as inconsistent refining processes or lower-quality raw materials. Over time, exposure to light, oxygen, or high temperatures can also cause oxidation, making the color darker. A deeper oil color is often a warning sign that the oil has not been stored properly or is no longer fresh.

From the consumer’s perspective, significant color differences in the same type of edible oil can raise doubts about quality, negatively affect sales, and even damage the brand’s reputation. This is why precise edible oil color measurement and color consistency control have become key challenges for oil manufacturers.

By using a liquid colorimeter, producers can obtain objective, digital color data, such as Lab values, to manage product quality and maintain a consistent appearance. Unlike subjective visual checks, a professional oil colorimeter ensures accurate detection of color variations, helps standardize oil color, and verifies that every batch matches the predefined standard. This not only improves production efficiency but also strengthens brand recognition and consumer trust.

2. Application of Liquid Colorimeter in the Pharmaceutical Industry

Color variations in the same type of liquid medicine can result from changes in raw materials, crystal forms, or manufacturing parameters, all of which can affect the quality of the drug. In some cases, active pharmaceutical ingredients may undergo chemical degradation when exposed to light or oxygen, leading to noticeable color changes. Because of this, color is a critical indicator for monitoring the quality of pharmaceutical products. Any change in color may signal reduced efficacy or the presence of harmful degradation byproducts.

Compared to traditional visual inspection methods, a liquid colorimeter provides more accurate and objective color measurements for liquid medicine. This technology allows pharmaceutical companies to establish consistent color standards, strictly control quality and batch uniformity, and conduct in-depth studies on the stability and reactivity of drugs. By tracking color changes during accelerated testing or long-term storage, the liquid colorimeter enables comprehensive and precise quality monitoring to ensure compliance with national and international standards.

Why Choose the Linshang LS155 Liquid Colorimeter

With the increasing stringency of food and pharmaceutical safety regulations, quality control for edible oils and liquid medicine faces higher standards than ever before. Traditional visual color evaluation is no longer sufficient to meet modern testing needs. Accurate, digital color measurement has become an essential requirement for standardized production. The Linshang LS155 liquid colorimeter offers significant advantages in edible oil color measurement and pharmaceutical testing:

Multi-parameter testing: A single device can measure multiple parameters, including color, color difference, transmittance, turbidity, and transmittance spectral curves, making it a versatile tool for both oil color and liquid medicine analysis.

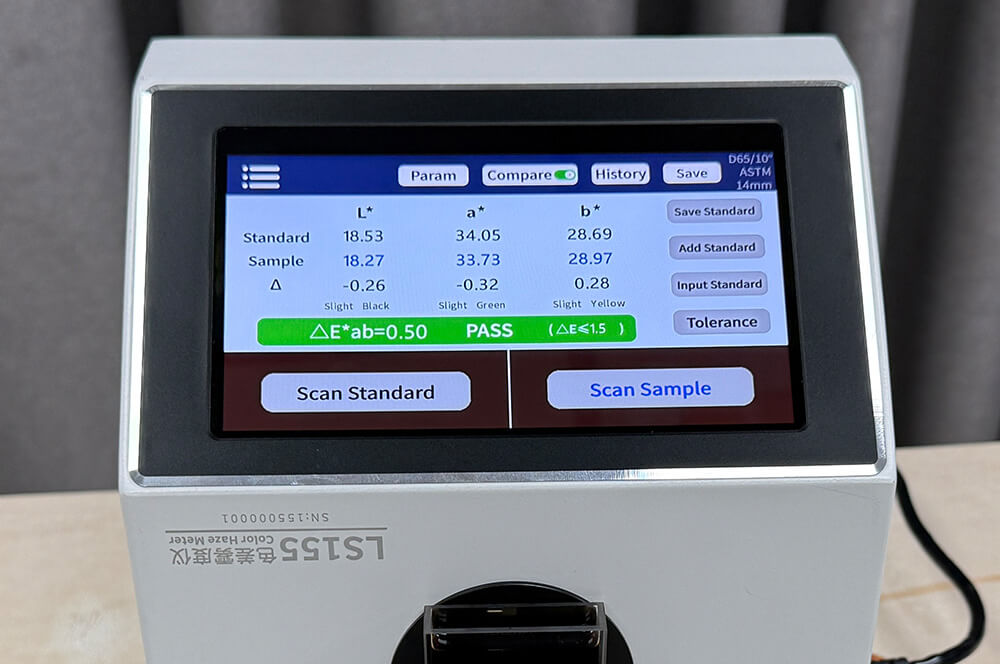

High-precision measurement: With repeatability below 0.03, the LS155 provides objective, stable data that effectively eliminates errors caused by human visual judgment.

User-friendly operation: Featuring a 7-inch touchscreen, the LS155 allows direct operation for liquid color testing. The total color difference (△E) is displayed clearly, providing faster and more intuitive results compared to traditional visual inspection, significantly improving efficiency.

Resistant to environmental interference: Unlike standard light boxes that can be influenced by light sources, angles, or observer differences, the liquid colorimeter delivers objective and accurate results in any environment, reducing subjective bias.

Comprehensive process management: LS155 enables real-time monitoring of the entire production process, from raw liquid medicine materials to final product testing, ensuring complete quality traceability and control.

How to Measure the Color of Edible Oils and Liquid Medicines with a Liquid Colorimeter

Linshang LS155 liquid colorimeter is designed for professional testing of various transparent and semi-transparent liquids. It helps businesses improve product consistency and strengthen competitiveness.

Here’s a step-by-step demonstration of how to use the LS155 liquid colorimeter for edible oil color measurement:

LS155 liquid colorimeter measures edible oil

The process of measuring the color difference of liquid medicine is exactly the same:

Place the liquid colorimeter horizontally on a stable surface.

Pour the liquid medicine to be tested into the cuvette.

Position the cuvette at the testing port.

Select the desired parameters and start the measurement.

The Linshang LS155 liquid colorimeter not only measures color differences in liquids but also provides data on transmittance, turbidity, platinum-cobalt color, and transmission spectral curves. By using the liquid colorimeter for scientific testing, the color, transmittance, and other optical properties of edible oils and liquid medicine can be accurately quantified and controlled. This ensures greater product consistency and competitiveness for businesses while giving consumers confidence when selecting edible oils or pharmaceutical products. With its efficiency, objectivity, and precision, the Linshang liquid colorimeter is setting a new standard for quality testing in the edible oil and pharmaceutical industries.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.

- The Definition of Optical Density and the Measurement

- Anticorrosive Coatings Thickness Measurement Using Paint Thickness Meter

- Thermal Insulation Effect of Stick-film and Coated glass | Tint Tester

- How to Select Suitable Automotive Paint Meters

- Test Glassine Transmittance by Diffuse Transmission Material Transmittance Meter

- Distinguish the Type of Paint with a Paint Gloss Meter