A Fabric Colorimeter in the Textile Industry

In the textile industry, maintaining accurate and consistent fabric colors is critical for quality control. From design and development to mass production, and from sample approval to final delivery, fabric color quality impacts every production stage. However, variations often occur due to differences in dye formulas, production processes, and lighting conditions. To achieve efficient fabric color matching and ensure long-term color consistency, companies rely on strict color standards and professional instruments. A fabric colorimeter delivers precise, repeatable color measurements, making it faster and easier to detect and correct color differences. Compared with traditional visual inspection, a fabric colorimeter ensures more reliable, objective, and standardized results. Understanding the common causes of color variation, the methods for measuring color differences, and the relevant industry standards is key for any textile business. Using a fabric colorimeter, companies can ensure high-quality, consistent colors, reduce production errors, and improve overall efficiency.

Common Causes of Fabric Color Differences

Fabric color differences are common in the textile industry. Understanding the main causes is key to improving fabric color matching.

Dye and process variations: Different dye formulas or inconsistent process control between batches can lead to noticeable color differences.

Fiber type differences: The same color may appear differently on cotton, polyester, or blended fibers.

Lighting conditions: Colors can look different under natural light, fluorescent light, or LED lighting.

Improper finishing: Processes like setting, printing, or coating can change the final color.

Overall, fabric color differences can result from many factors. Using a fabric colorimeter and optimizing equipment and process parameters can help reduce color variation.

How to Test Fabric Color Differences

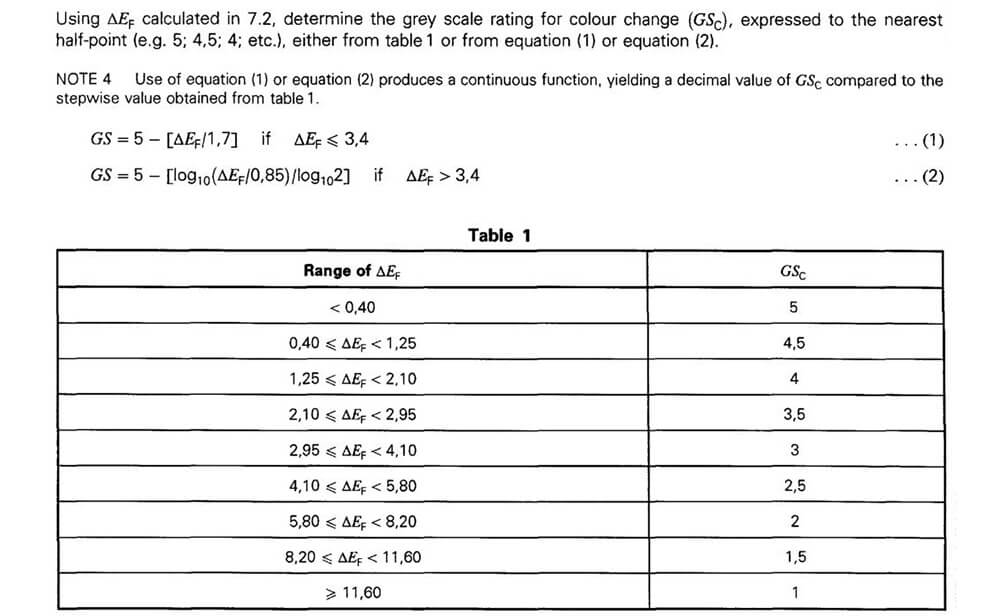

In the textile industry, measuring fabric color differences is crucial for quality control. Differences are usually evaluated using ΔE values or gray card grades.

Visual assessment: This traditional method requires trained inspectors to check fabrics under D65 standard lighting using a gray card. Inspectors carefully compare front and back, left and right, and overall fabric areas.

Fabric colorimeter testing: A fabric colorimeter gives precise ΔE values, offering objective and reliable measurements. Using a fabric colorimeter improves efficiency and reduces errors compared to visual inspection alone.

What Level of Fabric Color Difference Is Acceptable

In textile color standards, gray card grades are divided into levels 1–5.

Level 5: No color difference, ideal but rarely achieved in practice.

Level 4: Slight color difference is allowed. This is the minimum acceptable standard.

Level 3 or below: Not acceptable.

According to ISO 105-A05:1996, using a fabric colorimeter, the ΔEF value for acceptable fabrics should be 2.1 or less. ΔEF is typically calculated using CMC(2:1) or CIE2000 methods.

Why Use a Fabric Colorimeter to Measure Fabric Color Differences

In the textile industry, fabric color matching is critical for ensuring consistent quality from design to production. Large-aperture colorimeters are widely used to measure fabric color differences. A 20mm measurement aperture collects data from a larger area, making color readings more accurate, especially on textured fabrics. Using the LS175 large-aperture fabric colorimeter offers several advantages compared to traditional visual assessment methods.

Objective Results: Visual assessment can be affected by light conditions, viewing angles, observer sensitivity, and experience, leading to color perception errors (such as metamerism). A fabric colorimeter has a built-in standard light source, allowing testing under consistent conditions and avoiding subjective bias.

High Accuracy and Repeatability: Human eyes are less sensitive to differences in some color areas, which can cause errors in visual assessment. A fabric colorimeter can achieve measurement repeatability within 0.03, providing stable results even after multiple measurements.

Fast and Efficient: Visual inspection requires multiple people and discussions. A fabric colorimeter provides quick color comparisons in just a few steps, making it ideal for batch testing and quality control.

Quantifiable and Standardized Data: Visual assessment often uses vague terms like “similar” or “slightly different.” A fabric colorimeter provides precise color data, showing shifts such as red, yellow, or blue, making it easier to establish consistent quality standards. Color measurements from a fabric colorimeter can be saved, transmitted, and shared, supporting quality control and client communication.

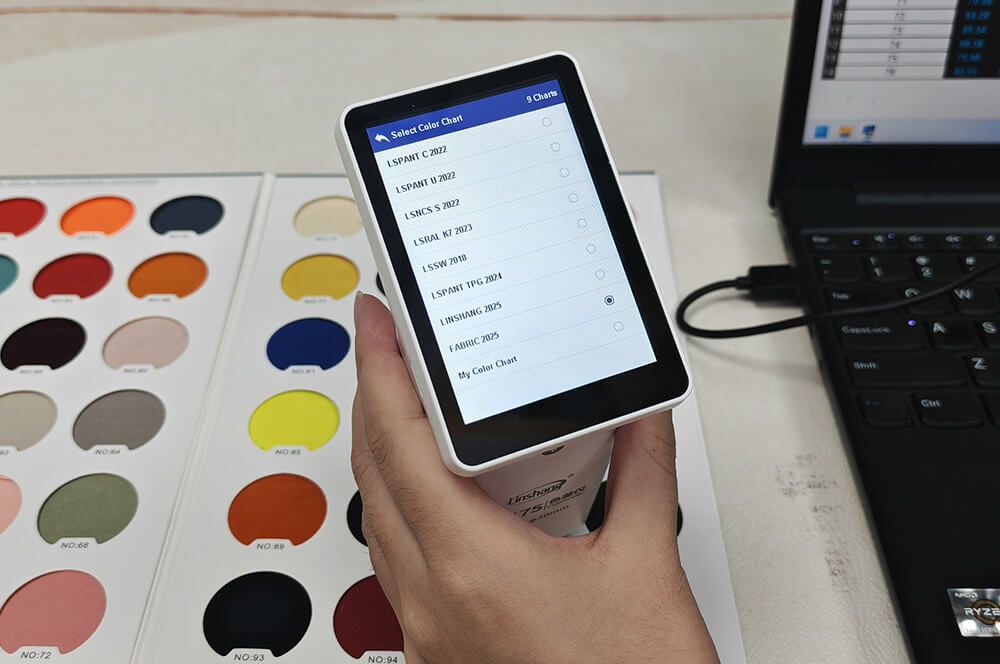

Built-in Universal TPG Color Charts: TPG color charts are widely used in home textiles, apparel, fashion accessories, and leather industries. The LS175 fabric colorimeter automatically identifies the three closest TPG colors when measuring fabric, enabling faster and more accurate color matching.

Create and Save Own Color Charts: Some textile manufacturers have proprietary or frequently used colors. The LS175 supports creating and saving color charts. Once the colors are uploaded, the instrument can match measured fabric colors to the three closest charts in the color palette and show ΔE values. This simplifies sample verification and fabric color comparison, reduces errors and significantly improves measurement efficiency and color consistency.

How to Measure Fabric Color Using a Fabric Colorimeter

A fabric colorimeter is an essential tool for textile manufacturers to ensure consistent fabric colors. Here’s how to use it:

Matching Fabric Colors with a Fabric Colorimeter

For fabric color matching, start by preparing the fabric to be tested and setting the fabric colorimeter to color measurement mode.

Select the color charts you want to use for fabric color matching. You can use the built-in color charts or your custom color charts.

Place the fabric colorimeter on the fabric and click “Scan.”

The instrument will measure the fabric color and display the three closest color matches from the selected color charts.

Measuring Fabric Color Differences (ΔE)

Prepare the standard fabric and the sample fabric. Set the fabric colorimeter to color difference mode.

Place the instrument on the standard fabric and click “Scan Standard.”

Place it on the sample fabric and click “Scan Sample.”

The fabric colorimeter automatically displays the ΔE*ab value and indicates whether the sample color passes the set tolerance.

The Linshang LS175 fabric colorimeter is not just a high-precision measurement tool. It is a key solution for fabric color matching in the textile, dyeing, and apparel industries to achieve standardized colors and efficient production. Its built-in TPG color charts meet general fabric color matching needs, while the ability to create a custom color palettes helps users manage colors professionally and strengthen their brand identity. Choosing Linshang fabric colorimeter means choosing a reliable, efficient, and continuously innovative fabric color matching solution—enabling precise color control at every step.

Get in Touch

If you have any questions or requirements, please contact us and we will get back to you right away.

- PC and ABS Material Gloss Control and Detection

- UVA LED Light Source Application in the Medical Equipment Field | UV Integrator

- How to Use Bluetooth Paint Thickness Gauge

- Insulated Glass Thickness Meter Used in Engineering Acceptance

- Linshang High Precision Glass Check Thickness Meter For Sales

- Difference between LS182 and WP4500 Window Energy Profiler