How to Measure Ground Bolt Galvanized Layer Thickness?

In order to prevent corrosion, the bolts are usually galvanized on the surface. The grounding bolt is one of the bolts, which is mainly used to fix the grounding wire. Zinc plating on the grounding bolt surface is to prevent corrosion, rust and maintain good conductivity. There are two main ways of galvanizing: hot galvanizing and cold galvanizing. The galvanized layer thickness of the grounding bolt can usually be measured with a galvanized coating thickness gauge.

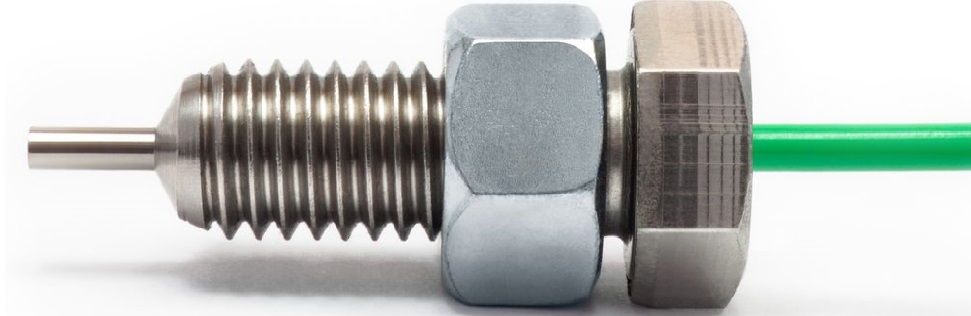

Image quoted from loja.nkl.com.bra

1. What is hot galvanizing?

This is an effective metal anti-corrosion method, mainly used in metal structure facilities in various industries. The rust-removed steel parts are immersed in a molten zinc solution at about 500°C. The zinc layer is adhered to the surface of the steel member, thereby achieving the purpose of anticorrosion.

Ground bolt(Image quoted from loja.nkl.com.bra)

2. What is cold galvanizing?

Cold galvanizing is to hang the workpiece that has also been degreased and derusted, showing no dirt and infiltration, onto the cathode in a special electroplating bath. Connected to the DC power supply, the zinc ions on the anode migrate to the cathode. Then discharge on the cathode, so that the workpiece is coated with a layer of zinc.

3. Hot-dip galvanized ground bolt

Hot-dip galvanized grounding bolts are grounding bolts that, after degreasing and derusting, present a surface that is free of dirt and infiltration. Next, immerse the ground bolt immediately in a plating bath that has previously been heated and melted by zinc to form a layer of zinc on the workpiece surface. A key to the corrosion resistance of hot-dip galvanizing is the plating thickness. The average thickness of hot-dip galvanizing generally exceeds 50 μm.

4. Measurement of ground bolt galvanized layer thickness

Therefore, the importance of hot-dip galvanized ground bolt thickness measurement is evident. The general bolt material is steel, which belongs to the ferromagnetic metal substrate. Therefore, measuring the galvanized layer thickness of the grounding bolt requires a galvanized coating thickness gauge using the magnetic induction principle. The magnetic induction galvanized coating thickness gauge is suitable for measuring non-magnetic coatings such as copper, zinc, tin, chromium, on ferromagnetic metal substrates such as steel and iron. Linshang LS225+F500 is a professional galvanized coating thickness gauge for measuring the thickness of bolts and screws with ultra-thin plating. This galvanized coating thickness gauge has ultra-high precision, up to ± (2% reading + 0.3μm) five-point calibration.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge