Colorimeter Used in Plastic Products Industry

Plastic products can be seen everywhere in life. In order to make plastic raw materials show different colors, you need to use various pigments and toners to match colors. In the process of artificial color matching of plastic products, due to the differences in pigments and processes, it is easy to produce color differences. In order to maintain the consistency of the plastic products color, a colorimeter is required.

I. How to control the color difference of plastic products?

Our common plastic raw materials are PE polyethylene, PP polypropylene, PA nylon and other materials. The raw material particles are white or opalescent semi-industrial plants. In order to form products with different colors, special dyes will be used to convert plastics. The products are made into various colors. However, in the specific coloring operation, the proportion of the coloring agent component and the auxiliary agent will affect the appearance color of the final product. In order to make the color difference of the plastic raw material within a reasonable range, the common method in the industry is to adjust it through a colorimeter.

There are two types of colorimeters in common use. One is a simple colorimeter and the other is a spectrophotometer. The color difference instruments eliminate artificial factors that affect the color difference evaluation results.

1. What is colorimeter?

A simple colorimeter cannot accurately measure the tristimulus value and chromaticity coordinates of an excellent source, but it can accurately measure the color difference between the two samples. It is easy to use the standard template for correction and output multiple color difference values. The products are managed in batches, with simple operation and high efficiency.

2. What is spectrophotometer?

The spectrophotometer measures the reflection coefficient of the completely diffuse reflection surface by measuring each wavelength and processes the measured data. The standard observer and standard light source provided by CIE are used to calculate the evaluable chromaticity value and other various values according to a certain formula. The advanced spectrophotometer with built-in oscillator has the functions of 0%, 100% automatic correction and magnification increase, thus improving the accuracy. Due to the high performance of the spectrophotometer, it is very expensive. If you have limited budget or just need simple color different comparison, colorimeter would meet your requirements.

II. Testing plastic products with colorimeter

The evaluation of color difference is very important in industry and commerce, mainly the color matching in production and the color quality control of products. Modern color difference evaluation is based on the standard color difference formula recommended by the International Commission on Illumination (CIE). It is accurate as commonly used CIE1976L*a*b* and CIE1976L*u*v* color difference formulas.

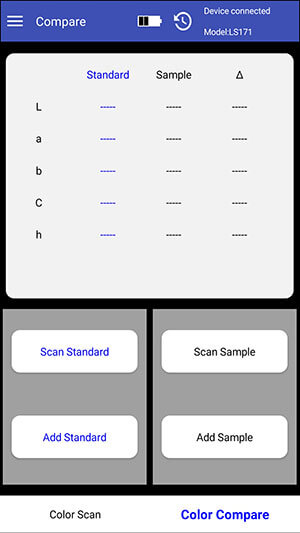

Colorimeters are widely used in plastics, printing and dyeing industries. Mainly according to the laboratory of CIE color space, Lch principle, the measurement shows the color difference △E and △lab value of the sample and the tested sample. How to measure plastic color?

-

Prepare test samples and colorimeter

Before testing, select the appropriate sample. If there is obvious stain on the sample surface, it will affect the measurement accuracy. The measuring aperture of the colorimeter may be contaminated by the sample. In the choice of colorimeter, it is necessary to choose the colorimeter product of the manufacturer. Some inferior colorimeter can’t guarantee the accuracy of the color measurement result.

-

Colorimeter calibration

Only a colorimeter that has been calibrated can make measurements. If it is calibrated, the test results are likely to be biased. Take Linshang portable colorimeter as an example, every time you turn on the instrument, you can choose to perform calibration or just skip calibration. Simple white board calibration makes the color measurement more realible.

-

Start measurement

We mark the prepared test sample as 1 for the standard sample and 2 for the product being measured. Then start measuring the color difference between the two. Place the sample at the measuring port of the instrument. Remember to block the measuring port so that it does not leak light.

Comparative analysis of color difference

Measure the color difference between the two samples. The Lab and Lch values of the test material are measured. Then compare the color difference standards for analysis.

In summary, the application of colorimeters in plastic products is very extensive and important. We have rich experience in color measurement and we're happy to share. If you have any questions, please contact us at sales21@linshangtech.com!