How to Choose a High-Precision Ultrasonic Thickness Gauge: A Complete Beginner’s Guide

If you need to measure the thickness of materials like metal, plastic, or glass non-destructively using an ultrasonic thickness gauge, the variety of models and technical specs on the market can feel overwhelming. How do you choose a high-precision ultrasonic thickness gauge that’s accurate, easy to use, cost-effective, and won’t let you down? That’s a common concern for many beginners. This article will guide you step-by-step—from addressing common beginner concerns and explaining key parameters to recommending specific models—so you can make an informed choice with confidence.

Common Problems Beginners Face When Choosing a High-Precision Ultrasonic Thickness Gauge

-

Too Many Models to Choose From

There are countless ultrasonic thickness gauges on the market. Many users are confused by technical terms like “multi-echo,” “high-frequency probe,” and “auto calibration.” Different materials—such as metal, plastic, paint, or ceramics—require different instruments. Beginners who aren’t clear about their actual application needs often end up choosing the wrong model.

-

Unsure Which Features Really Matter

Many beginners don’t know which technical specs to prioritize. Should you look for higher resolution, a wider measuring range, or advanced functions like waveform display? Without guidance, users might pay for features they don't actually need—or miss out on ones that would improve accuracy and efficiency.

-

Worried About Difficult Operation or Inaccurate Results

Concerns about complexity and measurement inaccuracy are common. In reality, many modern high-precision ultrasonic thickness gauges are designed to be highly user-friendly. Linshang’s series, for example, comes with standard calibration blocks, intuitive graphical interfaces, detailed user manuals, and complete operation videos. Even without professional training, beginners can use them with ease.

Understand Key Technical Parameters to Make the Right Choice

-

Sound Velocity Range

Sound velocity is the core element in ultrasonic thickness measurement. Since each material transmits sound waves at a different speed, accurate measurement depends on setting the correct sound velocity. Linshang’s high-precision ultrasonic thickness gauges feature a built-in sound velocity library, the ability to reverse-calculate sound velocity from known thickness, and manual input options—making them suitable for a wide range of materials.

-

Measuring Range

Different models support different thickness ranges. Some models measure from 0.8mm to 600mm, ideal for thick materials. Others handle ultra-thin measurements from 0.013mm to 1mm, perfect for coatings, plastic films, and other thin layers.

-

Resolution

Resolution indicates the smallest thickness unit the instrument can display. High-precision models usually offer 0.001mm or 0.01mm resolution, which is essential for applications requiring extreme accuracy.

-

Measurement Error

Measurement error determines the reliability of results. The smaller the error, the more reliable the instrument. Linshang's high-precision thickness gauges typically offer an error margin within ±0.05mm, sufficient for most industrial inspection needs.

Recommended Linshang High-Precision Ultrasonic Thickness Gauges

With nearly two decades of experience in developing measuring instruments, Linshang offers a series of high-precision ultrasonic thickness gauges that excel in performance, ease of use, and value. These instruments are widely used in metal processing, pipeline corrosion detection, automotive manufacturing, aerospace, and more.

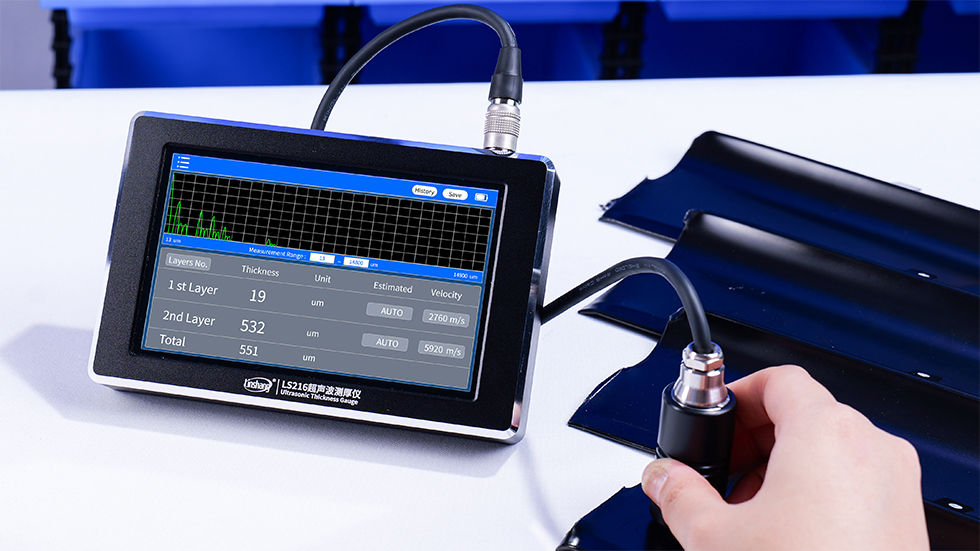

LS216 Multi-Layer Ultrasonic Thickness Gauge

Conventional gauges can’t measure the thickness of individual layers in multi-layer materials. For such cases, the LS216 ultrasonic thickness gauge is the ideal solution.

Key Features:

Simultaneous measurement of up to 3 layers

High-speed ADC data acquisition with 0.001mm resolution

800×480 color touchscreen for intuitive operation

Echo waveform display for viewing data at different positions

Built-in velocity values for over 20 materials

Customizable velocity settings for up to 18 materials

Storage for 999 sets of test data

Range and estimated thickness settings to filter interference echoes

Auto gain adjustment based on material type and thickness

Precision engineering with aerospace-grade aluminum casing

LS211 / LS212 / LS213 Ultrasonic Thickness Gauges

For measuring the thickness of common single-layer materials like metal, plastic, and ceramics, Linshang offers three high-precision models—LS211, LS212, and LS213—that are praised for their performance and ease of use.

Model |

Resolution |

Measuring Range |

Recommended Applications |

LS211 |

0.001mm |

0.8mm–600mm |

Thick structural parts, castings, large equipment |

LS212 |

0.001mm |

0.8mm–350mm |

High-precision needs, such as molds and components |

LS213 |

0.01mm |

0.8mm–350mm |

General material testing, light industry applications |

LS216 Ultrasonic Thickness Gauge Test Metal Substrate

LS211 Ultrasonic Thickness Gauge Test Pipes

LS212 Ultrasonic Thickness Gauge Test Glass

In Conclusion

To select the right high-precision ultrasonic thickness gauge, it's crucial to clarify your needs, understand the technical parameters, and choose the right model. Linshang offers a comprehensive range of high-precision instruments for both single- and multi-layer materials, helping users achieve efficient and accurate thickness measurement.

- Influencing Factors and Working Principle of Coating Thickness Gauge

- Choose Greenhouse Film with Transmittance Meter

- Waterproof UV Light Meter | UV Lamp Disinfection Precautions

- Use Coating Thickness Tester to Measure Dry Film Thickness

- How Do I Use A Glossmeter to Measure Gloss?

- How to Detect the UV Light Source Printer?