Dry Film Thickness Measurement Using Dry Film Thickness Gauge

Dry film thickness measurement can be performed using dry film thickness gauge. Dry film thickness gauge can measured the dry film thickness on the material surface nondestructively. Both dry film and wet films can be used as raw materials for wiring.

Dry film: Dry film refers to any coatings when dry.

Wet film: WFT is the measured thickness of any applied wet paint that is liquid-based.

What is the difference of dry film and wet film ? Is paint film thickness control necessary? How to measure the dry film thickness nondestructively? Answers will be revealed in this paper. Today, we will introduce the dry film applied in PCB board.

1. Difference between dry film and wet film

The functions of the dry film and the wet film are basically similar, but if the surface of the substrate is not flat and does not need to be too thick or too thin, the wet film can be considered. Dry film is more suitable for perforated circuit boards, or when the working environment is not easy to keep clean, it is also recommended to use a dry film that is easy to control.

(1) Dry film advantages

Dry film is easy to operate, the unit price is slightly higher than the wet film. However, the dry film is easy to keep clean and does not have to be baked, so it is convenient to use. However, if a thin film thickness is required, especially a thickness of 15μm or less, dry film is not recommended.

(2) Wet film advantages

The wet film has a good filling ability, but the curing requires a higher ultraviolet exposure energy.

In summary, although the wet film material is relatively inexpensive, it cannot be used anywhere. When choosing wet film or dry film, it is still necessary to take the manufacturer's own operating environment requirements into account.

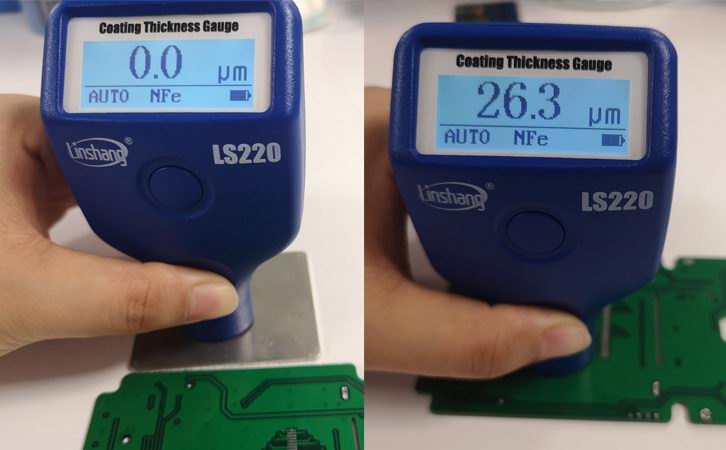

2. Dry film thickness measurement (Non destructive testing)

Dry film thickness gauge usually use the non-destructive methods such as magnetic measurement principle , eddy current principle and ultrasonic measurement principle. Magnetic dry film thickness gauge is used to measure the non-ferromagnetic coatings on ferromagnetic metal substrates. Eddy current dry film thickness gauge is suitable for the non-conductive coating measurement on non-magnetic metal substrates. Linshang LS220H dry film thickness gauge is a dual use coating thickness measuring instrument which use both magnetic measurement principles and eddy current principles. Now, we'll introduce the Linshang LS220H dry film thickness gauge.

3. Integral dry film thickness guage-LS220H

The dry film thickness gauge LS220H can switch between iron-based, nonferrous-based freely. It is very convenient to use it when the user need to conduct the dry film thickness test.

The advantages of LS220H coating thickness gauge are as below:

Ruby probe with abrasion and corrosion resistance to ensure long service life. Avoids errors caused by wear.

High accuracy and good repeatability.

Small size which is convenient for carrying around.

Fast measurement which can be completed in 0.5S.

4. Seperate dry film thickness gauge-LS221

If you need to test the dry film thickness in a narrow place, you can also choose LS221 split dry film thickness gauge. You can test the thickness with one hand and view the test data with another hand. This dry film thickness gauge has the same functions as the LS220H dry film thickness gauge. You can choose a suitable instrument according to your needs.

If you need to measure the thickness of the wet film, it’s recommended to use a non-contact thickness gauge, also called ultrasonic thickness gauge. For more information about the dry film thickness gauge, please refer to "Coating Thickness Gauge Selection and FAQ".

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge