Plating Thickness Measurement Equipment Features and Principles

Plating thickness measurement equipment can be divided into the following five types according to the measurement principle:

1. Different measurement principles for plating thickness measurement equipment

(1) Magnetic thickness measurement method

For thickness measurement of the non-magnetic conductive layer on the magnetic conductive material is applied. The magnetic conductive materials are mainly steel, iron, silver, nickel and the like.

(2) Eddy current thickness measurement method

Eddy current measurement principle is suitable for thickness measurement of non-conductive layer on conductive metal. The principle of eddy current measurement is simply that a high-frequency AC signal generates an electromagnetic field in the probe coil. An eddy current is formed when the probe is close to a conductor (generally a metal). The size of the eddy current has a certain relationship with the distance between the probe and the conductive substrate. The closer the probe is to the conductive substrate, the larger the eddy current and the larger the reflection resistance. When the probe is farther from the conductive substrate, the eddy current will be smaller and the reflection impedance will be smaller. So this quantity directly indicates the size between the probe and the conductive substrate, that is, the coating thickness.

(3) Ultrasonic thickness measurement method

Ultrasonic thickness measurement principle is suitable for thickness measurement of the thickness of the multi-layer coating which both the magnetic thickness measurement method and the eddy current thickness measurement method cannot be measured, but the coating thickness gauge using such a principle is generally higher in price.

(4) Electrolytic thickness measurement method

This method is different from the above three thickness measurement methods. The electrolytic thickness measurement method is not a non-destructive test. This method needs to destroy the coating layer and is more troublesome to measure.

(5) Radiation thickness measurement method

The coating thickness gauge using this principle are very expensive and suitable for special occasions.

The most common principles used by plating thickness measurement equipment in the market are the first and second.

2. Linshang plating thickness measurement equipment features

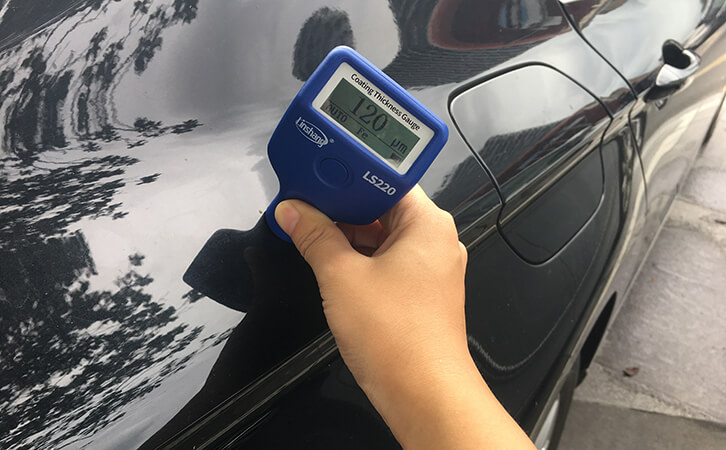

The Linshang Plating thickness measurement equipment LS220H uses the first and second measurement principles. The product features of the Linshang plating thickness measurement equipment are as follows:

The plating thickness measurement equipment is made of ruby and has strong abrasion resistance and corrosion resistance to ensure long-term use.

The measuring interval of the instrument is 0.5s, which means that the response speed of the instrument is higher than the reading speed of the user.

Linshang plating thickness measurement equipment has temperature compensation function and adopts digital signal transmission mode. Compared with the analog signal, the digital signal enhances the anti-interference ability of the data, making the test data more stable.

The probe automatically recognizes the material of the measurement substrate and switches to the Fe or NFe measurement mode.

Before using the plating thickness measurement equipment, it only needs to be zeroed on the equipped zero adjustment board or the uncoated substrate. It is not necessary to use the standard film for calibration. The preparation time before measurement is greatly reduced.

LS220H Plating Thickness Measurement Equipment

In addition to the above points, the Linshang LS220H plating thickness measurement equipment also has high precision. The instrument can ensure pass the inspection by the Chinese national metrology agency. Want to know more details about Linshang plating thickness measurement equipment? You can refer to "Coating Thickness Gauge Selection and FAQ".

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge