Measurement Principle and Application of Coating Thickness Gauge

I. Principle of coating thickness gauge

1. Principle of magnetic thickness measurement

When the stylus touches the coating, the stylus and the magnetic metal material matrix form a closed magnetic circuit. The presence of the non-magnetic coating layer changes the magnetic resistance of the magnetic circuit.The coating thickness layer can be calculated based on the accurate measurement of the transformation .

2. Eddy current thickness measurement principle

The high-frequency alternating current is used to create a magnetic field in the magnetic coil. When the stylus touches the covering layer,an eddy current is caused on the metal material substrate.It has a feedback effect on the magnetic coil in the probe. The size can be calculated to the thickness of the cover layer.

II. Application of coating thickness gauge

1. Plating process and painting

The coating thickness gauge is most widely used in this area,the thickness of the plating layer is an important indicator of the coating quality, because it will greatly affect the service life of the product.

2. Steel pipe anticorrosion

The thickness detection of anti-corrosion coatings is important for anti-corrosion management systems. From the practical application point of view,the service life of the coating increases with the increase of the coating thickness.Therefore, increasing the thickness of the paint layer and improving the protective effect of the coating will be a very important way to increase the service life of the steel pipe. Simply put, the coating thickness is a key indicator of whether the anti-corrosion coating works. Accurately measuring the thickness of anticorrosive coatings will be one of the most critical quality inspection indicators for anticorrosive coatings.

3. Aluminum profile

In recent years, due to the implementation of compulsory regulations in China and the renewal of licenses by aluminum companies, a new good trend has emerged in this field. The air oxide film on aluminum is mainly measured.According to statistics,each manufacturing company has one μm or one ton less aluminum material can "save" 150 yuan, which is very considerable. Therefore, China has mandatory regulations to configure relevant testing instruments including coating thickness gauges.

4. Steel frame structure

According to the specification of "Steel Structure Fireproof Coatings", the quality and classification of steel structure fireproof architectural coatings have been determined. Architectural coating products can be divided into three types: thick, thin and ultra-thin steel frame structures.If the fireproof architectural coating thickness of the steel structure is unqualified, it will not achieve a very good fire safety protection effect. It is also important to inspect the thickness of anticorrosive and fireproof safety coatings for steel structures.

5. Packaging printing route plate, ink printing and other fields

There are various routes on the package printed circuit board, so moisture,corrosion and water resistance become the key to coating on the package printed circuit board. Because once these three processes have the same quality or the coating is not qualified, it will endanger the function of the electronic equipment and even short-circuit failure, which may cause damage to the electronic equipment when it is more serious. The requirements for the thickness inspection of anti-corrosion coatings for packaging and printing route plates have also gradually increased.

III. Selection of coating thickness gauge

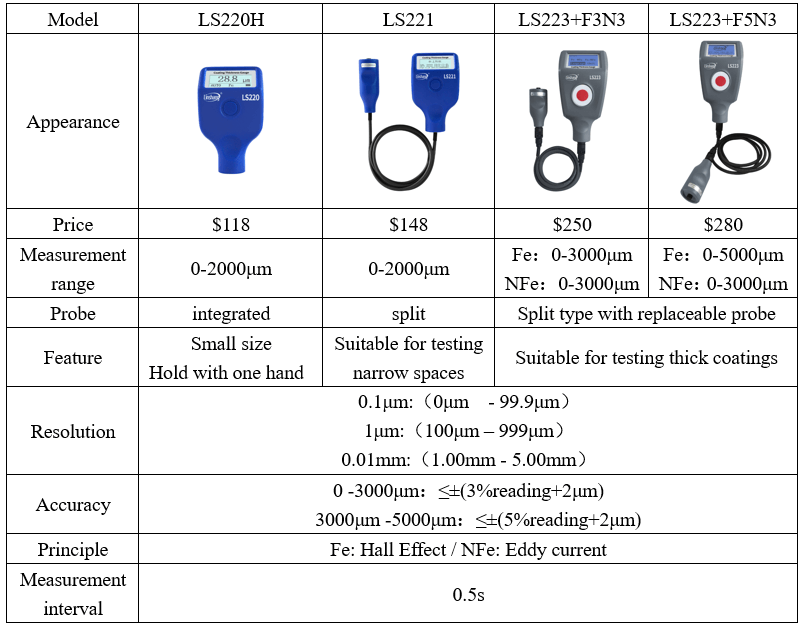

Linshang coating thickness gauge is widely used in automotive paint surface thickness inspection, hardware surface coating thickness inspection, anti-corrosion coating thickness inspection and other industries.The main parameters and features in the middle of different models and specifications are selected as follows:

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge