Factors Affecting Fire Performance of Fire-resistant Coatings

The main factors affecting the fire performance of fire coatings

1. The authenticity of fire-resistant coatings. Along with the hot sale of fire-resistant coatings, some people intent on selling fake and shoddy products in order to make huge profits. Some fake and shoddy products not only do not prevent fire, but also support combustion. Therefore, we must pay attention to authenticity when purchasing fire-resistant coatings.

2. Select a suitable fire-resistant coating. Some people do not understand the properties of fire-resistant coatings, causing some unscrupulous merchants to recharge during the purchase process, so that the fire-resistant coatings purchased do not meet the basic requirements of building fire protection. Sometimes, the purchaser's unintended choice will also cause the fire protection coating selected to fail to meet the fire protection requirements of the building. Therefore, before buying fire-resistant coatings, you must first understand the selection of fire-resistant coatings according to requirements and pay attention to the fire resistance grade of fire-resistant coatings. According to relevant national regulations, the fire resistance rating of fire-resistant coatings can be divided into first and second grades.

3. Select a suitable fireproof coating according to the surrounding environment. Outdoor fireproof coatings can be used for indoor fire protection, while indoor fireproof coatings cannot be used outdoors. Because the indoor and outdoor environments are different, the use of indoors and outdoors will cause some fire-resistant paint to fall off and not cause fire.

4. Whether the treatment of the substrate before the fire-resistant coating is qualified. Before painting the fire-resistant coating, it is necessary to perform simple treatment on the surface of the substrate, such as dust and wood shavings. They need to grind and repair the material to prevent uneven coating. When the steel structure fireproof coating is applied, the steel structure surface is rust-proof and anti-corrosive cleaned up to prevent the fireproof coating from falling off due to the rust of the steel structure surface.

5. When applying fire-resistant paint, consider whether the current environment meets the requirements. If the ambient temperature is 0 to 40 ° C, the temperature of the substrate is 5 to 45 ° C and the relative humidity of the air is not more than 90%, the environmental conditions are up to the standard. Then painting can be performed. At the same time, the construction site must be maintained air circulation, the wind speed is not more than 5m / s and there is no cross wind. It is not suitable for outdoor work when the surface of the construction component is dewy.

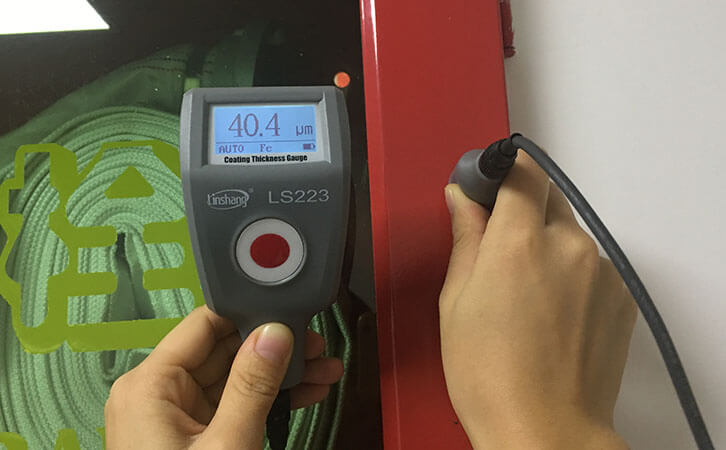

6. Use the Linshang paint thickness tester to check whether the fire-resistant coating thickness has reached the standard. When the fireproof coating thickness is uneven, the fireproof performance of the fireproof coating will be unstable, so that the substrate cannot meet the corresponding fireproof requirements.

7. After the coating is applied, it is necessary to use Linshang paint thickness tester to check whether the thickness meets the standards, whether there is leakage, less coating, uneven brushing, coating bulging, etc.

8. After the construction of the fireproof coating is completed, the curing and maintenance of the fireproof coating should be done well. The freshly sprayed coating should be protected from rain and direct sunlight. The coating will cure within 48 to 96 hours at normal temperature.

9. When cleaning the construction tools and waste materials, do not damage the coating or damage the coating film.

In summary, there are several factors that affect the fire resistance performance of fireproof coatings. I hope that it will help everyone in the process of selecting fireproof coatings. At the same time, the thickness of the coating must be tested with a paint thickness tester to ensure the coating quality.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge