Application of Anticorrosive Coating on Highway Guardrail

We know that highway guardrails play an important role in traffic safety and preventing traffic accidents. In order to improve the safety performance, the guardrails of expressways are generally designed with special anticorrosive performance. The metal treatment on the surface of common highway guardrails is usually hot-dip galvanized. In order to ensure its anti-corrosion performance, increase the service life of highway guardrails and reduce production costs, it is necessary to carry out standard inspections from three aspects: the amount of galvanized layer adhesion, the uniformity of galvanized layer and the adhesion performance.

How to check whether the anti-corrosion performance of the hot-dip galvanized wave guardrail meets the standard? By tapping the zinc layer and checking the peeling and protruding phenomenon of the zinc layer, the adhesion of the galvanized layer of the highway guardrail can be detected. The strength, plasticity and impact toughness of the galvanized layer on the surface can be tested to determine its mechanical properties. In order to check whether the amount of galvanized layer on the surface thickness of the guardrail galvanized layer have reached the standard, it is necessary to use an galvanized coating thickness gauge for relevant tests.

The thickness of the anti-corrosion coating on the highway guardrail is regulated by national standards and must be tested by a professional galvanized coating thickness gauge. The zinc used for galvanizing layer adhesion test shall be zinc 0 or zinc 1 specified in GB470. According to the relevant industry standards for transportation facilities, in the 2007 "Highway Corrugated Beam Steel Guardrails" standard for hot-dip galvanized corrugated beam steel guardrails and columns, the average galvanized adhesion of hot-dip galvanized steel in the beam plate is 600g \m2, the average coating thickness is 85μm or more. For hot-dip galvanized and pure polyester electrostatically sprayed double-coated corrugated beam steel guardrails and columns, the average plating thickness of the beam plate should be greater than or equal to 270g \ m2, and the average thickness of the plastic coating layer should be greater than or equal to 76 pillars. Without this standard, the effect of the anti-corrosion coating on the guardrail is not as obvious as imagined. It may easily cause peeling and falling, etc., which not only affects the appearance, but also easily aging and loosening.

The anti-corrosion coating on the highway guardrail requires a special coating process. Sometimes a double-compliant anti-corrosion coating is also used for maintenance to ensure that it will not fade, shed or rust within a certain period of time. The thickness of the anticorrosive coating has a great influence on the final anticorrosive effect. In the loading of the anticorrosive coating, if there is a cut-off of materials, or a thin coating of the anticorrosive coating is used to save costs. Weather conditions such as rain and snow will cause serious corrosion and the guardrail will be easily damaged. Therefore, the use of a high-precision galvanized coating thickness gauge to ensure that the thickness of the anti-corrosion coating meets the requirements is an indispensable part.

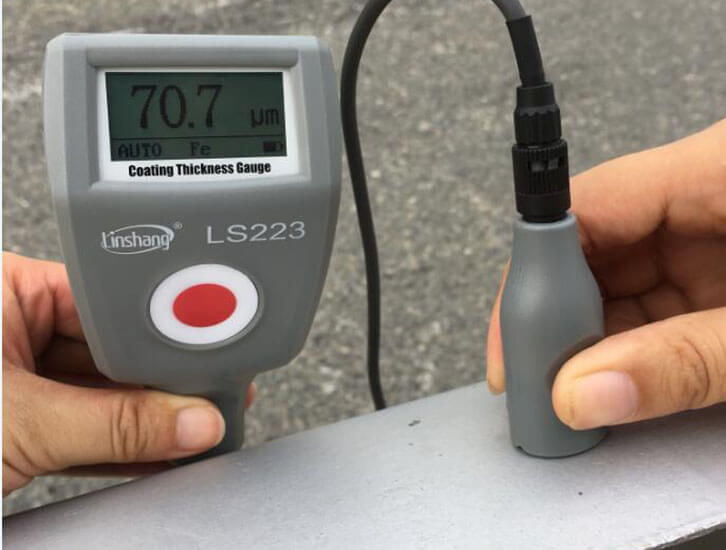

The thickness of the anticorrosive coating on the highway can be measured by Linshang LS223 galvanized coating thickness gauge. The LS223 galvanized coating thickness gauge has high measurement accuracy, meets national measurement standards. The instrument is portable and more resistant to corrosion and abrasion with longer service life. It is an ingenious choice for the thickness measurement of anti-corrosion coatings on highways.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge