Leather grain surface gloss meter in the automotive interior industry

Leather grain surface gloss meter is an instrument used to determine the reflective ability of the object surface to light, its essence is to measure the size of the mirror reflective ability of the leather grain surface to light, light source and receiver in a fixed angle conditions, light beam irradiation on the leather grain surface reflected back the intensity of light divided by the standard plate reflected back the intensity of light, and then multiplied by the standard plate gloss value, is the gloss of the leather grain. Next, we will introduce the application of leather grain surface gloss meter in automotive interior industry.

Why leather grain surface gloss is measured in the automotive interior industry

The application of leather grain in the automotive interior industry has two main purposes, one is the decorative function, the leather grain can cover up the defects on the surface of the light panel parts, so that the appearance of the parts is better. A good leather effect is closely related to its gloss, and the right gloss will enhance the quality of the car interior. The second is the protection function, that is, to prevent the interior parts from being scratched in the process of repeated use, to prevent leaving scratches. Leather grain can resist cuts, can effectively protect the parts, to avoid the interior parts in the process of repeated use left scratches, affecting the appearance.

1. Types of leather pattern

Leather pattern processing is a process of transferring a specific pattern to the surface of the mold. Nowadays, there are basically leather texture, geometric technology texture, brushed texture and sand texture, etc. Different kinds of leather texture correspond to different degrees of gloss.

2. The process of leather grain surface gloss

The traditional way of processing leather grain is through the manufacture of molds for processing, mainly in the mold for chemical corrosion processing treatment. Mould surface gloss adjustment, through sandblasting and other means to adjust the gloss to the host factory requirements within the gloss range. Usually for multi-layer texture, repeated printing and oxidation are required

3. Design method of leather pattern

Leather design to ensure the consistency of the interior effect and the consistency of the overall texture of the interior, different textures on the surface of the same form of different colors will bring different visual effects, because different textures of light absorption, reflection and transmission is different, the surface texture of the bumpy changes often cause the surface of the difference between light and dark expanded, even if the same form, the same material with the same color performance, if Material surface texture difference is large, will also produce a different luster effect.

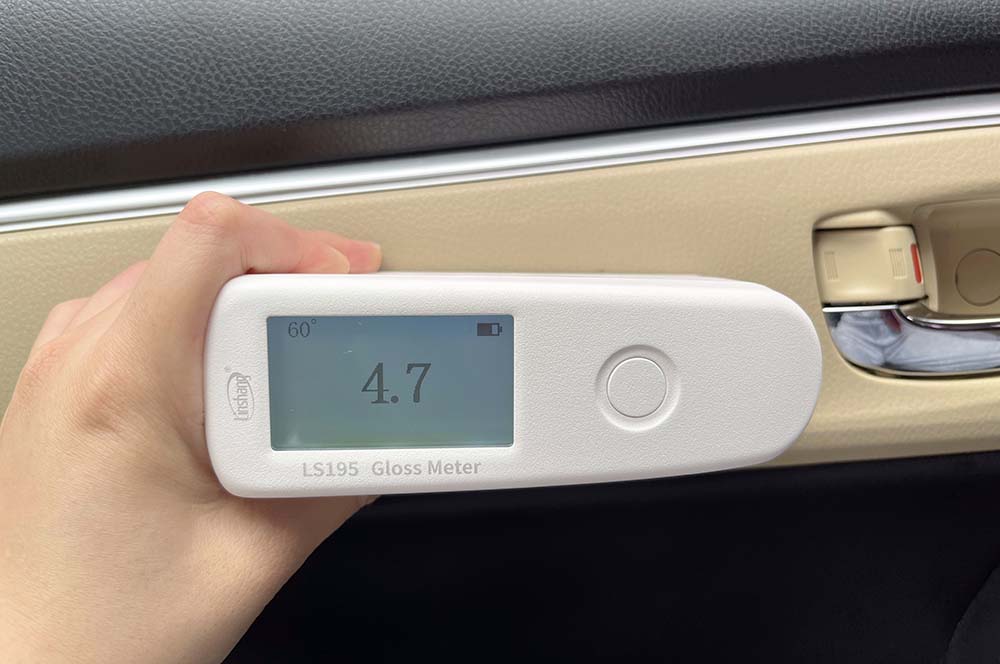

The application of leather grain surface gloss meter in the automotive interior industry

1. Design requirements for glossiness of leather surface

Generally, the surface gloss of automotive interior leather pattern parts is controlled at about 2.0. Because of the low gloss of the automotive interior leather surface, it is necessary to use 85° leather surface gloss meter for measurement. Here we recommend the use of Linshang's LS197 gloss meter, with 3 kinds of angles with super high cost performance, high precision, to ensure that it can pass the national level work machine testing standards.

2. Leather grain surface gloss verification

After the production of auto interior parts, we need to approve the appearance of the surface skin pattern of the parts. The appearance of the recognition that the overall evaluation of the appearance of the quality of the parts (including color, gloss and surface quality) to meet the requirements of the design standards. Among them, whether the surface gloss processing of leather grain meets the standard, generally through a combination of visual and measurement to determine the way, the use of leather grain surface gloss meter measurement, general leather grain surface gloss design standard value of 2.0 ± 0.3 gloss units.

The above is the introduction of the application of leather surface gloss meter in the automotive interior industry all content. If you want to know more detailed information about Lin Shang products, you can always consult our customer service.

- Measuring Method and Principle of Paint Thickness Gauges

- Dry Film Thickness Gauge Principles

- Recovering patients Are Infected Again? These Measures Need To Be Taken

- Method for Judging Gloss of Wood Coating

- Frequently Asked Questions about UV Sterilization | UV Ligh Tester

- How to Choose the Suitable UV Irradiance Meter