Use and Maintenance of Ultraviolet Lamp

With the promotion of emerging UV curing coatings, inks and other photopolymerization materials and UV light radiation (ultraviolet radiation measuring instrument) light source, in the printing and coating and such industries, ultraviolet high pressure mercury lamp is used more and more widely, but due to the technical operators do not quite understand,while in using, also happened in the many problems, matters needing attention are as follows:

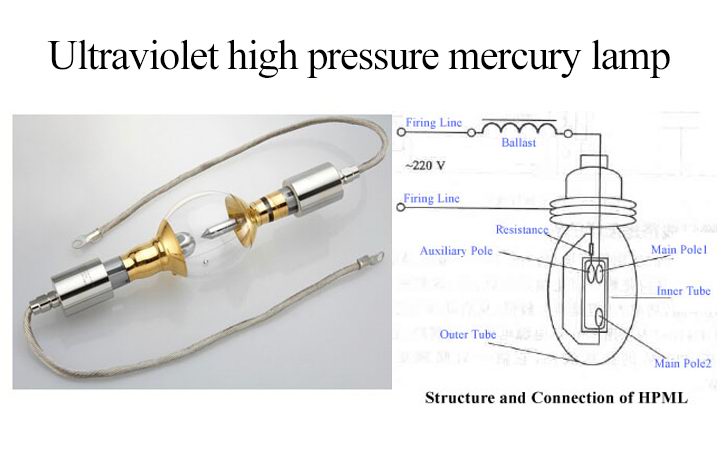

UV lamp must be matched with the ballast, magnetic leakage transformer and capacitor, all matching can be used.

Must be in accordance with the wiring diagram of the installation.

The installation of the lamp light box must to be fitted with a good air cooling system, to ensure that the tube heat radiating and the substrate does not heat deformation.

Before install tube on the machine, must with gauze dipped in rubbing alcohol to wipe the outer wall of the lamp tube, so to wipe off fingerprints and oil and other impurities, otherwise it will cause ignition made tube non-transparent, if the UV cured material has high content of volatile solvents or working environment was polluted by dust and dirt, please every other week with alcohol wipe the lamp tube once, to ensure that the tube is not premature loss of transparency.

In the entire use process, between lamp holder and lamp contact point should be maintained good contact, otherwise it will cause serious cap oxidation, resulting in tube sealing cracking.

UV lamp must be start in a cooling state. Once again, the need to wait for the UV lamp completely cool before starting, 5 minutes later, the frequency of the switch is more frequent, the lamp life is shortened accordingly.

The average life expectancy of new light source factory high pressure mercury lamp is 00-1000 hours and when normal work the surface temperature of the lamp is 600 to 700 DEG C. Mainly related to the starting frequency of the lamp tube.

The lamp and transformer is strictly prohibited work in the state of overload, so as to avoid the occurrence of lamp explosion or transformer burning accident. Mains voltage fluctuations should not be too large, such as a sudden decrease of more than 5%, may result in self extinguishing. Where the lamp burn caused by tube burst do not belong to the intrinsic quality of tube, is used improperly, not to return.

The transformer must have a good natural ventilation conditions, so that good for heat dissipating.