How to Judge the Attenuation of the Light Source in UV Curing?

UV light curing has the advantages of short curing time and environmental protection. In the process of UV curing, the UV power puck is used to detect energy.

In fact, in theory, there are many factors affecting UV curing, of which the intensity of the light source is particularly important. UV sources are attenuated after a period of use. So how do you judge the attenuation of the light source in UV curing?

At this time, we need to use the UV mil gage to determine whether the light source is still valid. If the light source is attenuated, the lamp can be replaced in time or the process parameters can be adjusted.

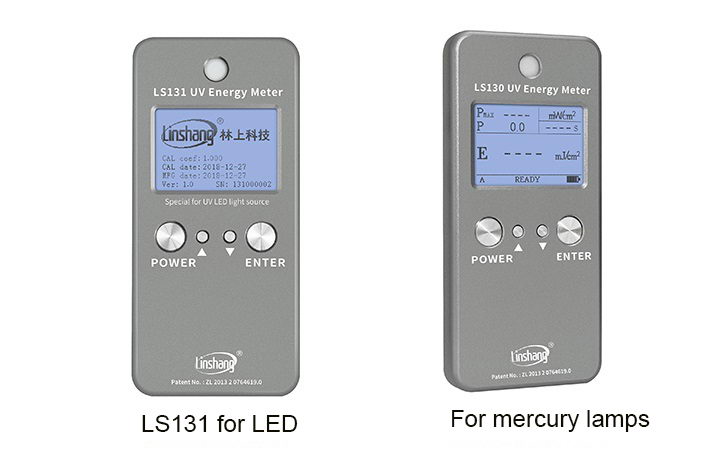

The light source used in UV curing has a conventional high-pressure mercury lamp and an emerging UV LED lamp. For the different light sources, the UV power puck is also dedicated to test mercury lamps and UV LED.

The UV power puck independently developed by Linshang Technology is divided into LS130 for testing mercury lamps and LS131 for testing LED for different light sources. The test data of Linshang UV power puck can be totally compared with EIT UV power puck. The instrument can simultaneously display the measured power real-time value, power maximum value, energy value and measurement duration. The length of UV curing time can be accurately known by measuring the length of time. And there is also a power curve display. In addition, you can connect to a computer, read detailed test data, and print a test report.

Many customers give feedbacks that the LS130 and LS 131 UV power puck can replace the EIT UV power puck and meet their daily requirements.