How to Choose Paint Thickness Gauge for Corrugated Guardrail?

A few days ago,we received a telephone consultation from a manufacturer in Chongqing who produced corrugated guardrail.The customer wanted to find an anti-corrosion paint thickness gauge for detecting the thickness of the anti-corrosion coating of the corrugated guardrail. The ordinary carbon structural steel used in the corrugated guardrail produced by the customer, the cold-formed steel parts of all the wave beam guardrails are treated with anti-corrosion treatment. The zinc used in hot dip galvanizing should be "zinc ingot". No. 0 zinc or No.1 zinc specified in (GB470-83).

1. Corrugated guardrail anti-corrosion layer thickness national standard

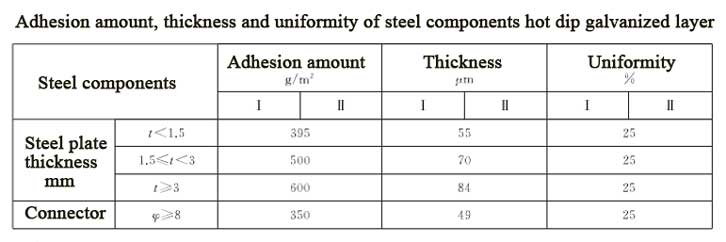

The national standard BG/T 18226-2015 "Technical Conditions for Anti-corrosion of Steel Components in Highway Traffic Engineering" clearly defines the thickness of hot-dip galvanized layer of steel components. Different thickness steel plates have different galvanized layer thickness requirements, as shown in the following table:

2. Necessary testing instrument for corrugate guardrail-----anti-corrosion paint thickness gauge

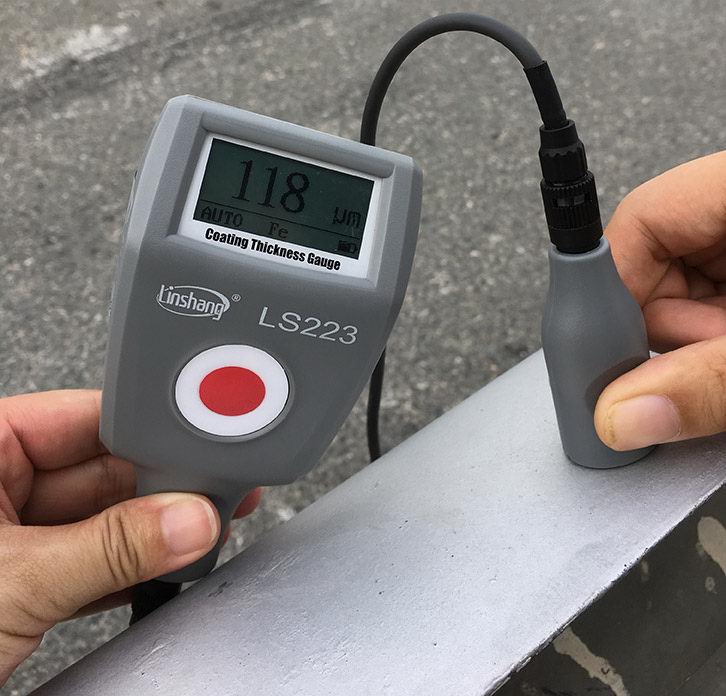

For the detection of corrugate guardrail anti-corrosion coating thickness,an anti-corrosion paint thickness gauge is required.The thickness of the conventional corrugate guardrail steel plate is about 3-4mm.The average galvanized layer thickness is greater than 84μm according to national standards.For some areas with particularly severe corrosion or for aesthetic requirements, the guardrail steel components will be galvanized.Plastic or paint, so the thickness of the entire coating will increase.The following is a picture that we use paint thickness gauge detect the corrugated guardrail coating thickness.

3. Some points to note when choosing an anti-corrosion paint thickness gauge:

Anti-corrosion paint thickness gauge must be accurate enough, the best paint thickness gauge manufacturers promise that the instrument can pass the inspection of the national measurement.

The method of using the instrument should be simple enough.Most anti-corrosion paint thickness gauges on the market require cumbersome calibration to determine the accuracy of the instrument.Generally, non-professionals are very likely to cause wrong operation. Therefore,the portability of the instrument is very important.

The service life of the instrument must be guaranteed.In this respect,it can be seen from the technical parameters of the products provided by the manufacturer that the good anti-corrosion paint thickness gauge probe is generally made of ruby material.The ordinary instrument is made of steel material.The ruby probe has wear-resisting and corrosion-resistant characteristics to make sure the instrument lasts longer.

For more applications on the Linshang anti-corrosion paint thickness gauge,please click on the "Common Application Areas of Anti-corrosion Paint thickness gauge"

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge