Commonly Used Electronic Thickness Gauge Supplier |Price |Classification

The electronic thickness gauge is an coating thickness measuring instrument used to measure the coating thickness of the material or the covering layer thickness on the material surface. It is widely used in industrial production, hardware manufacturing, mechanical equipment evaluation and other fields.

Why measure the thickness of the material? During production, it is important to make the product qualified and the coating thickness is moderate. Electronic thickness gauges are commonly used to continuously or sample the thickness of products. The thickness of some material components must be measured during manufacturing and maintenance. In order to let us better understand the uniformity, thickness, corrosion and wear of the material coating at various points; The cover layer thickness measurement on the surface of the component are also needed to ensure product quality and production safety.

Using a electronic thickness gauge to measure enamel, film, plastic, paper, steel plate, pipe, paint and other materials can help manufacturers formulate product parameters and ensure that the material thickness is within the acceptable range. Only when the thickness reaches the standard can high-quality products be produced.

I. Electronic thickness gauges classification

According to the different measuring principles adopted for electronic thickness gauges, the materials tested are also different. The more commonly used electronic thickness gauge principles include magnetic, eddy current, ultrasonic and electronic display tool gauges.

1. Portable electronic thickness gauge using magnetic principle

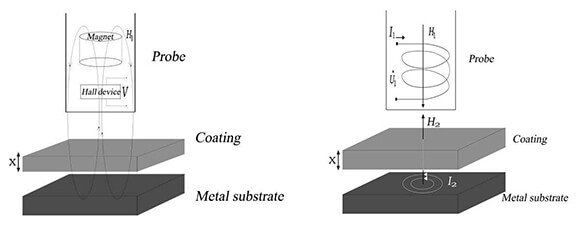

The principle of electromagnetic induction is applied to the measurement of the non-magnetic coating thickness on the magnetic metal substrate. The magnetically conductive materials generally include: steel, iron, cobalt, nickel and gadolinium.

2. Portable electronic thickness gauge using eddy current principle

Using the principle of eddy current measurement, it is suitable for non-destructive measurement of the non-conductive coating thickness on non-magnetic metallic materials, such as the thickness of anodized layers on aluminum, paints, coatings, plastics, etc. Magnetic electronic thickness gauges and eddy current electronic thickness gauges are widely used in machinery, automobile, chemical industry, shipbuilding, electroplating, enamel and other industries.

3. Portable ultrasonic thickness gauge using ultrasonic principle

Thickness measurement is based on the principle of ultrasonic pulse reflection. The thickness of the measured material is determined by measuring the propagation time of ultrasonic waves in the material. It is suitable for occasions where the above two principles cannot be measured and the general measurement accuracy will not be too high. It is suitable for measuring steel plates, steel pipes, plastics, ceramics, glass, metal materials, etc.

4. Portable electronic thickness gauge for electronic digital display measuring tools

Determine the coating film thickness according to the lever micrometer or dial indicator. The probe of this type of digital thickness gauge can be divided into flat head, pointed head and elbow. It is suitable for small area model test, such as thickness test of paper, film, leather, board, non-woven fabric and other sheet materials.

II. Electronic thickness gauge suppliers and price

The electronic thickness gauges with different principles, the manufacturers and the prices of the instruments are also different. Here is a brief introduction for everyone:

1. Electronic thickness gauge use magnetic principle + eddy current principle

Electronic thickness gauge is also called coating thickness gauge, coating thickness meter. Electronic thickness gauges commonly used in the market are generally made by combining these two measurement principles. Of course, there are also electronic thickness gauges that use a single measurement principle and users generally choose according to their needs. When measuring, press the probe directly on the measured object surface. This type of electronic thickness gauge is relatively simple to use.

Common electronic thickness gauges suppliers: Linshang Technology, Yuwen, Q-nix, etc. The price of electronic thickness gauges on the market: 400 -- 3000 RMB

2. Electronic thickness gauge made by ultrasonic principle

During the measurement, the coupling agent needs to be applied to the measured place. The result can be measured by coupling the probe with the measured material. Common portable ultrasonic thickness gauge manufacturers: Beijing Times, Cangzhou Europe Spectrum, Beijing Kaida, etc. The price of portable ultrasonic thickness gauge on the market: 200-2000RMB

3. Portable electronic thickness gauge

The electronic thickness gauge is also called handheld thickness gauge, film thickness gauge. Due to the limited shape of the instrument, it is suitable for testing materials with relatively small dimensions. When measuring, first put the tested material into the upper and lower probes to clamp, press the handle. Then the tested material thickness is displayed on the screen immediately.

Common portable digital thickness gauge manufacturers: Mitutoyo, Shanghai Liuling, Xiwaka, etc.

The price of portable digital thickness gauge on the market: 60-1000RMB

III. The Best 5 Electronic Thickness Gauges in 2020

● Measure coating thickness on ferromagnetic and non-ferromagnetic metal substrates

● Thickness measuring range: Fe:0.0-5000μm NFe:0.0-3000μm

● Coating thickness mesuring accuracy: ≤±(3% reading+2μm)

● Measure coating thickness on ferromagnetic and non-ferromagnetic metal substrates

● Paint thickness measurement range: 0.0-2000μm

● thickness gauge accuracy: ≤±(3% reading+2μm)

● Measure coating thickness on ferromagnetic and non-ferromagnetic metal substrates

● Coating thickness measurement range: 0.0-2000μm

● Coating thickness measuring accuracy: ≤±(3% reading+2μm)

● Measure plating thickness on ferromagnetic metal substrates

● Plating thickness measurement range: 0-500μm

● Accuracy: ≤±(2%+0.3μm) after calibration of 1-5 points

● Test fixture is optional to eliminate the measurement errors

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge