Painting Thickness Meter For Aluminum Alloy Coating Detection

Aluminum alloy has the characteristics of high strength and non-deformation. It is widely used in the fields of building structures, doors and windows, ceilings, decorative surfaces,etc. Due to long-term outdoor use, its anti-corrosion construction is an important part. Now it is mostly painted with aluminum fluorocarbon paint on aluminum profiles and aluminum veneers to fully play the role of fluorocarbon paint film's anti-corrosion and salt spray resistance. The coating plays a protective and decorative role. However, different coatings have different requirements on the paint film thickness. Only by meeting the film thickness requirements can the various properties of the paint film be effectively guaranteed. At this time, the painting thickness meter becomes very important!

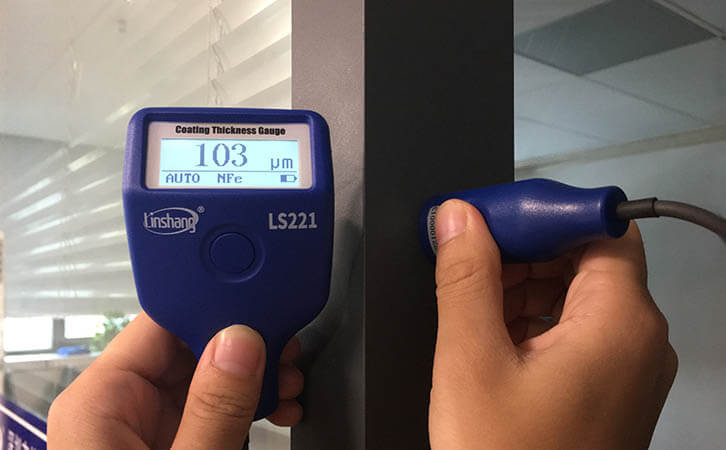

There are many painting thickness meters at home and abroad, but few are dedicated to coating measurement. Linshang painting thickness meter can be said to be one of the best inspection instrument. This painting thickness meter can not only be used to measure non-magnetic coatings (such as varnishes, coatings, enamels, chromium, zinc plating) on ferromagnetic substrates, but also can be used for measuring the non-conductive coatings (anodized layers or ceramics)on non-magnetic metal substrates such as aluminum, copper, die-cast zinc, brass, etc.

Below, we will tell you how to use the painting thickness meter.

Step 1: Prepare the tested object;

Step 2: Press the probe of the painting thickness meter vertically to the coating of the measurement object. When a beep is heard, the measured thickness value of the coating can be displayed on the screen. Lift the probe again and move it to another position.

Step 3: After the measurement is completed, press the power button to shut down.

The painting thickness meter is convenient to operate and the data is accurate. However, when using the painting thickness meter, these requirements require attention:

First, remove dust, fine debris, grease and corrosion products from the contact surface before measuring, but do not remove any covering material. When making zero adjustment, the substrate surface used must also be bare and smooth;

Secondly, the placement of the probe has a great influence on the measurement. During the measurement, the probe should be kept perpendicular to the surface of the device under test and the placement of the probe should not be too long, so as not to cause interference with the magnetic field of the substrate itself.

Again, don't drag the probe when measuring, because it will not only cause wear to the probe, but also affect measurement results;

Finally, if the user is unfamiliar with the instrument during the measurement process, the probe may be deviated from the measured material. The magnetic flux may be changed to cause an incorrect measurement. When the user uses the instrument for the first time, he must read the manual carefully and master the measurement method.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge