Paint Film Thickness Measurement

Paint film- a solid continuous film formed by one or more paint films on which the paint is applied to the substrate. Generally, the coating film is composed of multiple paint films. The paint film thickness is determined according to the requirements of the object to be coated. Generally including primer layer, intermediate paint film and top coat layer. The paint film thickness is an important process parameter, which plays an important role in the process of controlling product quality and cost and formulating process parameters. During the construction of the paint film, if the paint film thickness is uneven or the thickness does not meet the requirements, it will affect the performance of the coating. Therefore, a coating thickness tester will be used to ensure that the paint film thickness meets the standard and its uniformity.

This paper focuses on the measurement of paint film and introduces various methods of film thickness measurement and the coating thickness tester used.

I. Different types of film thickness measurement

Paint film can be divided into dry film and wet film. The wet film thickness is used to control and adjust the paint film thickness on the construction site and the dry film thickness is used for quality control and acceptance.

1.Wet film thickness measurement

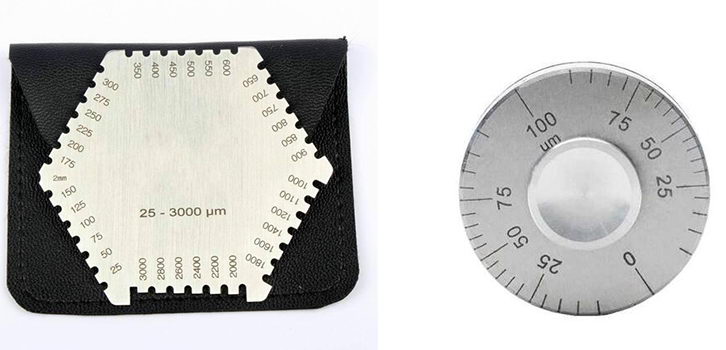

Wet film refers to the paint film in the wet state of the paint or paint during the coating process. In order to better control the change process of the paint film on the surface, engineers usually perform paint film thickness measurement when the coating is in a wet film state. The wet film tester depends on the shape of the measurement surface area and the measuring range of the wet film tester. Wet films are usually measured with wet film comb or wet film wheel.

(1) Wet film comb measure wet film thickness

The wet film comb is made of a flat piece of aluminum, plastic or stainless steel. There are calibrated notches on the edge of each surface. The periphery is composed of comb teeth. The outer teeth at both ends are at the same horizontal plane to form a baseline. The middle inner teeth have different gaps that rise in sequence from the horizontal plane, indicating different readings and paint film thickness values.

(2) Wet film wheel measure wet film thickness

It consists of three equally spaced wheels coaxially, the middle one is slightly smaller than the outer wheel. It is eccentric, with a height difference. The point it touches provides the thickness of the wet film. When the instrument rolls on the wet film, the wet film thickness can be read from the position where the edge of the middle wheel has just touched the surface of the wet film, corresponding to the scale on the outer wheel. These wet film wheels are relatively inexpensive and are only suitable as a guide, because the cured film may be different after flowing. The marks left by the wet film wheel may affect the characteristics of the cured film.

2. Dry film thickness measurement

Dry film refers to a dry paint film. There are usually a variety of methods for dry film thickness measurement. Common methods include magnetic induction and eddy current. The coating thickness tester is a paint coating thickness tester using the principle of magnetic induction or eddy current measurement. When using the coating thickness tester for dry film measurement, we usually choose the corresponding coating thickness tester based on the dry film substrate (ie, what surface the coating is applied to) and the test method.

II. Dry film thickness measurement method

1. Destructive measurement of dry film thickness

The paint film damage measurement method includes mechanical measurement method, wedge cutting method, optical cut method, electrolytic method, weighing method and so on. When these measurement methods measure the paint film thickness, the paint film will be damaged.

2. Non-destructive measurement of dry film thickness

In order not to damage the paint film during the measurement, most people need to use a non-destructive measurement method of the coating thickness tester. The nondestructive measurement method mainly includes the principle of magnetic induction, the principle of eddy current, the principle of ultrasonic measurement and the principle of X-ray. Non-destructive measurement is a method of measuring the paint film thickness based on the premise of not damaging the surface layer of the paint film. Due to its convenience and practicality, it is widely used in industry. In the following, several non-destructive measurement methods commonly used to measure film thickness will be described in detail.

III. Non-destructive film thickness measurement on metallic or non-metallic substrates

1. Measurement of paint film thickness on metallic substrate

(1) Thickness measurement on magnetic metal substrate

The principle of magnetic induction measurement is one of the non-destructive measurement methods of paint film thickness. The magnetic induction coating thickness tester can be used for the measurement of non-ferromagnetic coatings on ferromagnetic metal substrates (iron, cobalt, nickel, gadolinium, etc.). For example, iron zinc plating, iron copper plating, iron spray paint, iron spray powder coating, etc.

The magnetic induction coating thickness tester uses the magnetic flux of the probe flowing into the magnetic metal substrate through the non-magnetic coating to measure the coating thickness. In general, the thicker the coating on the substrate surface, the greater the magnetic resistance and the smaller the magnetic flux.

(2) Thickness measurement on non-magnetic metal substrate

Eddy current thickness measurement method is also a very widely used non-destructive measurement method of paint film thickness. The eddy current principle can be used for the measurement of non-conductive coatings on non-magnetic metal substrates (copper, aluminum, magnesium, zinc, etc.). For example, aluminum surface anodic oxide, copper spray paint, etc.

High-frequency AC signals generate electromagnetic fields in the probe coil. Eddy currents are formed when the probe is close to a conductor (usually metal). The size of the eddy current has a certain relationship with the distance between the probe and the conductive substrate. When the probe is closer to the conductive substrate, the eddy current will be larger and the reflection impedance will be greater. When the probe is farther away from the conductive substrate, the eddy current will be smaller and the reflection impedance will be smaller. The size between the probe and the conductive substrate is the coating thickness.

(3) Magnetic induction and eddy current dual-purpose coating thickness tester-Linshang coating thickness tester

Instrument design: integrated

Range: 0.0-2000μm

Accuracy: ≤ ± (3% reading + 2μm)

Instrument design: split

Range: 0.0-2000μm

Accuracy: ≤ ± (3% reading + 2μm)

Instrument design: split, probe can be replaced

Range: 0.0-5000μm for iron-based materials; 0.0-3000μm for non-ferrous materials

Accuracy: 0-3000μm: ≤ ± (3% reading + 2μm)

3000-5000μm: ≤ ± (5% reading + 2μm)

3.Paint film thickness measurement on non-metallic substrate

(1) Application of ultrasonic coating thickness tester

When measuring the paint film thickness on a non-metallic substrate, most users will use an ultrasonic coating thickness tester. Ultrasonic electronic thickness gauge can nondestructively measure a variety of film thicknesses, including surface coatings on composite materials, ceramics, plastics, concrete and other substrates. For example, thickness measurement of chrome / nickel / copper film on plastics.

(2) Principle of ultrasonic coating thickness tester

Ultrasonic coating thickness testers are used for thickness measurement according to the principle of ultrasonic pulse reflection. When the ultrasonic pulse emitted by the probe reaches the material interface through the object to be measured, the pulse is reflected back to the probe so as to measure the thickness of the material.

The above is all the information about the film thickness measurement that the editor wants to share. You can choose the appropriate coating thickness tester according to your material and the paint film thickness measurement method you want to use. For more information about Linshang dry film thickness gauge, please read " Coating Thickness Gauge Selection and FAQ".

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge