Measuring Tri-proof Paint Using Coaing Thickness Meter

Linshang coating thickness meter is widely used. This coating thickness gauge use ferromagnetic and eddy current principle. It can be used to measure the thickness of the non-magnetic coating on the magnetic metal substrate and the non-conductive coating thickness on the non-magnetic metal substrate. Let's focus on the application of Linshang coating thickness meter in the tri-proof paint industry.

1. What is tri-proof paint?

Tri-proof paint is a kind of paint, this paint uses a special formula is mainly used to protect the circuit board or other equipment from some environmental corrosion. The tri-proof paint generally forms a transparent protective film after curing (you can also add colors according to your needs) and has insulating properties. Its main functions are dustproof, anti-leakage, anti-moisture, anti-vibration, anti-aging, anti-corrosion and corona resistance.

2. Tri-proof paint application classification

Tri-proof paint is usually used in PCB electronic circuit boards. Due to the different needs of each circuit board, it is divided into the following types according to the chemical composition:

olvent-containing acrylic resin tri-proof paint, which is characterized by fast curing time, transparent color, cheap price, flexible texture, dry surface and easy repair. It is the most widely used tri-proof paint.

olvent-free acrylic resin tri-proof paint. This kind of tri-proof paint needs UV curing, curing time can be dried within a few seconds to tens of seconds, the texture is hard and the color is transparent. It has very good wear resistance and corrosion resistance.

olyurethane tri-proof paint. This tri-proof paint is characterized by a relatively brittle texture. It has excellent solvent resistance, good moisture resistance and stable performance in low temperature environment.

ilicone tri-proof paint. The characteristic of this kind of tri-proof paint is that the surface is soft and the coating material is elastic. The high temperature resistance can reach 200 ℃. And easy to repair

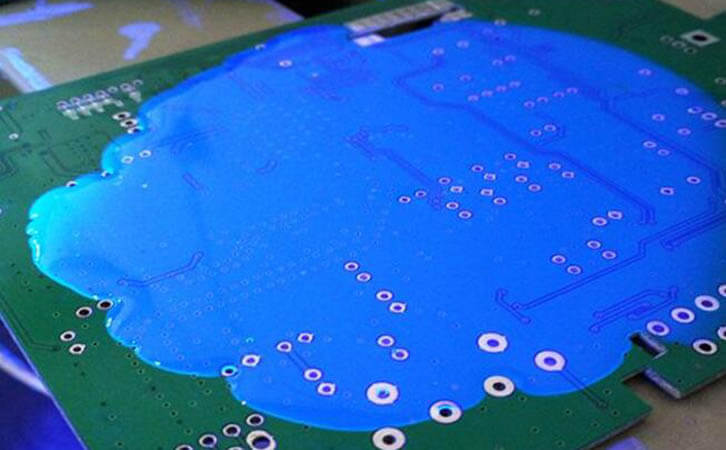

Fluorescent tri-proof paint. The characteristic of this kind of tri-proof paint is that the coating surface will turn blue after being irradiated by the purple light, which can quickly and easily detect whether the coating is in place.

3. Why do we use tri-proof paint on PCB board?

The "three protections" in the tri-proof paint mainly refer to waterproof, moisture-proof and dust-proof. Moisture is destructive to the circuit board. The PCB board uses tri-proof paints mainly for the following reasons:

Excessive moisture will affect the insulation resistance of the circuit board and corrode the conductor. (Excessive moisture will also appear patina)

The tri-proof paint is waterproof. Applying tri-proof paints can avoid conductor corrosion or short circuit.

It can avoid the erosion of PCB board caused by pollutants, such as human grease, fingerprints, cosmetics and food residues.

Applying Tri-proof paints on the circuit board and components can reduce the decline of electronic performance.

Applying tri-proof paints to the coated objects can make the coated objects withstand mechanical vibration, swing, thermal shock and high temperature resistance.

4. Tri-proof paint coating thickness standards

The tri-proof paint plays a huge role in the PCB board, so it has requirements on the process and coating thickness. For the general electronic products, the general coating thickness is required to be between 0.15-0.35mm. If the three-proof requirements are relatively high, wait for the tri-proof paint on the board to cure. The requirements for ordinary circuit boards are not too high. Generally, modified tri-proof paint or acrylic tri-proof paint is used. Both of these tri-proof paints have a good protection effect on the circuit board.

For some of the more demanding military products or industrial products, the requirements for the tri-proof paint are quite strict. And the silicone-modified tri-proof paint needs to be used. This tri-proof paint is characterized by high temperature resistance and flame retardant effect. The coating thickness is generally required to be between 0.35-0.6mm and the viscosity of the silicone should reach 1000. Within the above requirements, tri-proof paints can play a very good role in protecting the circuit board.

tipulations have been made clearly in the "tri-proof paint coating process specifications":

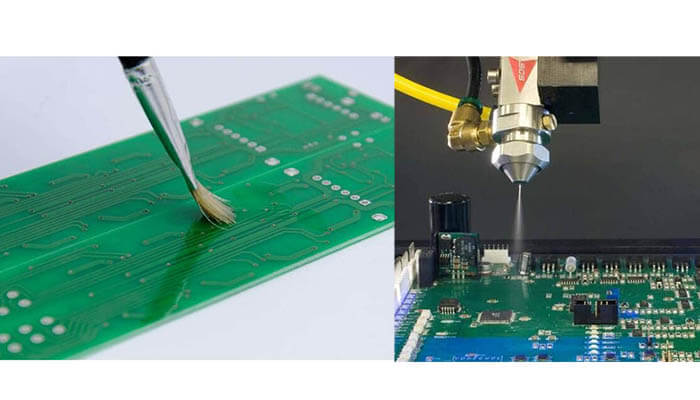

efore applying the tri-proof paint on the PCB, the PCBA board must be tested and assembled and thoroughly cleaned.

The brushes used should be kept clean. The brushes should be soaked with alcohol to ensure the next use.

The coating thickness of the coating layer is generally 30μm-130μm, if there are special requirements, you need to follow the engineer's requirements.

In "Military PCB Assembly Three Anti-coating Quality Control", it is stipulated that "Operating environment compressed air is not allowed to contain drops of water and mineral oil. The general decorative spray should be less than 0.5μm and the advanced decorative spray should be less than 0.03μm.

5. Test tri-proof paint thickness

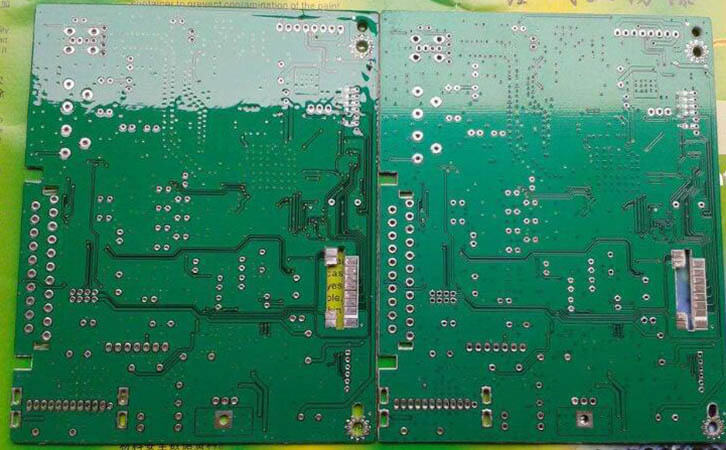

PCB board can be divided into single panel, double panel, four-layer board, six-layer board and multi-layer circuit board according to the purpose. The substrates of PCB boards can be generally divided into metal substrates (higher cost) and non-metallic substrates according to the major categories. Generally, a PCB board with a non-metallic substrate is used and a layer of copper is brushed on the non-metallic substrate as a conductor (traveling the line). Seal the parts that do not need to be conductive with insulating paint. Then brush a layer of tri-proof paint on top of the insulating paint.

The design principles of Linshang coating thickness meterare magnetic method and eddy current method. The magnetic thickness gauge can measure the non-magnetic coating thickness on the magnetic metal substrate. The eddy current thickness gauge can measure the non-conductive coating thickness on the non-magnetic metal substrate. The insulating paint and the tri-proof paint on the copper substrate on the PCB top are both non-conductive coatings, which make perfect use of the eddy current thickness measurement method.

In the following, we will take the sample sent to us by "Pu De Xinxing Power Technology Co., Ltd." as an example to make an actual measurement of the PCB board by the Linshang coating thickness meter. Pu Dexin Star Power Technology Co., Ltd. sent us four samples. Two of them are hand-painted three-proof. The other two are machine-sprayed tri-proof paint. We use Linshang coating thickness meter to measure the coating thickness of its insulating paint and tri-proof paint are 25.1 and 30.3 μm. The above is the information related to the tri-proof paint and its coating thickness measurement.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge