How to use the gloss meter for baking paint?

Baking paint is an emerging method of spraying paint production in the manufacture of furniture, refers to spraying paint after high temperature baking to set. Baking paint is also divided into a variety of different processes, divided into single-sided baking paint, double-sided baking paint. The gloss of baking paint is generally divided into bright, matte, pearl several, baking paint gloss value is an important acceptance criteria when the final baking paint parts factory. So how to measure the gloss of baking paint?

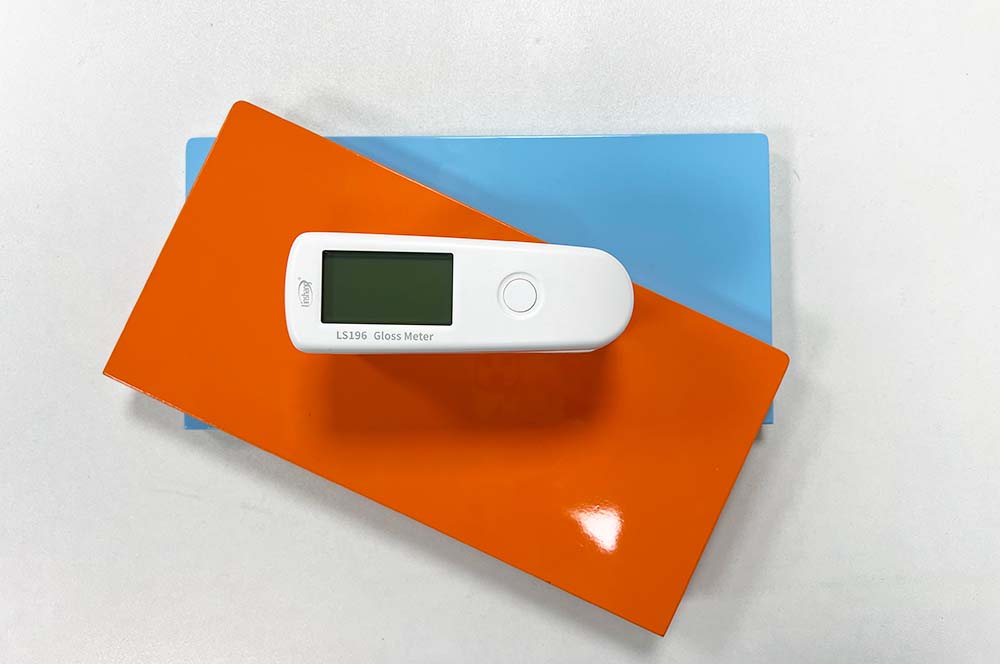

The first choice for measuring the gloss of baking paint is to use a baking paint gloss meter to measure the gloss value by using the mirror reflection ability of the surface of the baking paint parts to light. Gloss meter is generally divided into 60°, 45°, 20°, 85° 4 kinds of angle measurement value, when measuring the gloss of baked paint, generally choose 60° baked paint gloss meter. Here we recommend the use of LS196 gloss meter, with super high cost performance, 0-1000GU super range measurement without worry, high precision, can pass the national authoritative metrology institute testing, in line with the national level work machine standards.

Measurement method of gloss meter for baked enamel

Next, take Linshang's LS196 baked paint gloss meter as an example, and introduce how the instrument measures the gloss of baked paint.

-

Power on

Short press the power button to turn on the machine. Press and hold the power button to enter the setting interface in the off state, short press the power button to select, long press the power button to confirm. You can select the language (Chinese/English) and measurement mode (QC mode/normal mode) of the instrument respectively.

QC mode will automatically determine whether the measured gloss is within the set upper and lower limits, if it is within the limits, the instrument interface will show qualified when measuring, if it is not within the limits, the instrument measurement interface will show unqualified.

-

Calibration

Open the bottom cover of the instrument, wipe the standard plate on the bottom cover of the instrument with a cleaning cloth, then cover the bottom cover tightly and short press the power button to calibrate, then enter the measurement interface that is the successful calibration. If the calibration fails, check whether the bottom cover of the instrument is tightly covered.

-

Measurement

Place the instrument on the surface of the painted part, make sure the measured surface covers the measuring light hole of the instrument, and then keep it still, the corresponding gloss value will be displayed on the instrument screen.

Measurement techniques

As the baking paint technology is mostly used in the furniture industry, according to the national standard GBT4893.6-2013 Furniture Surface Paint Film Physical and Chemical Properties Test Part VI Gloss Determination Method, it is necessary to measure different positions or different directions within 50mm of the edge of the baked paint part under test, and for every 3 data measured, it is necessary to calibrate once to ensure that the instrument has no drift, and a total of 6 sets of data are measured

If the extreme difference of these 6 sets of data is less than 10GU or 20% of the average value, the average value and the range of these values will be recorded, otherwise, re-sample the measurement.