Anti-Corrosion Mil Thickness Tester

An anti-corrosion coating is a cover layer that is typically applied to a metal surface to isolate the preservative from the surrounding medium. The anti-corrosion layer generally has good electrical insulation and water barrier as well as strong adhesion on the surface of the pipe.It also has a certain mechanical strength and resistance to chemical damage. In order to check whether the anti-corrosion coating is qualified, we generally use an anti-corrosion thickness gauge to detect.

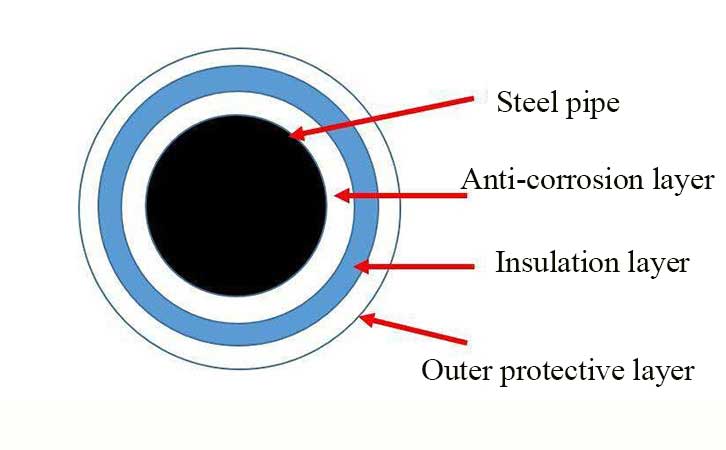

1. Components of the anti-corrosion coating

The anti-corrosion coating usually consists of three parts. The first layer is mainly a primer coated on a metal surface similar to a gel, the main role is to enhance the adhesion of the coating to the metal. The second layer is mainly an anti-corrosion coating layer. Commonly used anti-corrosion coatings include polyethylene adhesive tape, polyolefin coating, coal tar enamel, petroleum asphalt and the like. The third layer is mainly a banding belt. The main function is to prevent damage to the preservatives during construction or transportation.

2. Thickness requirements of anti-corrosion coating

GB50205-2001 "Steel Structure Engineering Quality Acceptance Specification" in the "Steel Structure Painting Project" stipulates that the thickness of the outdoor anti-corrosion coating shall be not less than 150μm detected by the anti-corrosion mil thickness tester. The thickness of the indoor anti-corrosion coating is generally 125 μm. The total thickness of the anticorrosive coating is allowed to have a deviation of 25 μm and the deviation of the dry paint film thickness of each coating is 5 μm.

When the pipeline is treated with 3PE for corrosion protection

The material of the first primer is generally a sintered epoxy powder, a solvent-containing epoxy, an epoxy resin, etc. It has a thickness about 50 μm. The second layer is mainly a variety of adhesives that act as adhesions in the middle. The value measured by the anti-corrosion mil thickness tester is generally between 250 and 400 μm. The third layer is mainly a polyolefin surface coating which mainly protects the machine or the pipe. The thickness thereof is generally 1.5-3 mm. In special circumstances, to prevent UV rays, a polypropylene coating may be added to the surface. The thickness of the coating is approximately 30-40 μm. Usually we use an anti-corrosion mil thickness tester to measure the thickness of the anti-corrosion coating.

3. Anti-corrosion mil thickness tester:

Anti-corrosion coatings are mainly used in various gas pipelines, communication cabinets, bus stop signs and other industries. Since the anti-corrosion layer is anti-corrosive, the anti-corrosion coating is usually thick. The measurement range requirement for the anti-corrosion mil thickness tester is relatively high. Usually we use the Linshang LS223 anti-corrosion dry film gauge to detect the thickness of the coating.

The Linshang LS223 anti-corrosion paint thickness gauge has the following characteristics:

Anti-corrosion mil thickness tester conforms to national standard "DIN EN ISO 2808 paint and varnish film thickness" and "JJG-818-2005 magnetic, eddy current cover thickness gauge verification procedure".

The instrument can automatically identify the measurement substrate and the measurement range is large: Fe: 0.0-5000μm, NFe: 0.0-3000μm. (Maximum measurable 5mm thick Fe material)

The only button for zero adjustment. Simple design and simple operation.

Adopt digital probes, with temperature compensation function. The measured data is not affected by temperature changes and the measured data is more stable.

The above is the relevant information of anti-corrosion coating and anti-corrosion mil thickness tester. Anti-corrosion coatings generally have to pass the test of coating thickness, anti-corrosion degree and acid resistance. In the coating thickness measurement acceptance, Linshang LS223 anti-corrosion mil thickness tester is a good choice.

- High precision coating thickness gauge for used car

- Automotive paint protection films coating thickness gauge

- Plating Thickness Measuring Instrument for Detecting Anti-corrosion Coating

- Linshang LS220, LS191, LS160A– Necessary for Car Cover Inspection

- Coating Thickness Gauge for Second Hand Vehicle

- Zero Adjustment Step of Coating Thickness Gauge