Why Will Plastic Parts Have Color Difference?

Plastics parts can be seen everywhere in daily life, but the problem of plastics parts chromatic aberration is inevitable. Only by understanding the reasons for the plastics parts chromatic aberration can we better control the chromatic aberration of plastics parts.

Why do plastics parts have color difference? How to determine the color difference of plastics parts? Plastics products are very common in life. Different plastics products will have a variety of colors. By detecting the differences in plastics colors, it is also an important means of judging product quality. This article will briefly introduce the occurrence of color differences in plastics parts.

I. Why will plastic parts have color difference?

Plastics are mainly polymer materials composed of synthetic resins and various plasticizers, stabilizers, lubricants and colorants. The plastics materials are generally transparent or opalescent. After dyeing, they will show various colors. However, due to the influence of different batches of raw materials and processes, it may cause color differences in plastics parts. Therefore, for manufacturers with strict color requirements, such as children's toys and medical materials. It is necessary to strictly control the color difference of plastics parts. . First, we need to understand the cause of the color difference of plastics parts:

1. Raw material factors

The characteristics of the resin itself have a great influence on the color and gloss of plastics products. Different resins have different coloring powers and some plastics have different colors. Therefore, considering the material and color of the raw materials, the coloring formula of plastics has a big impact.

The color of the raw material is also the color of the plastics. It is a factor that cannot be ignored, especially when configuring white or light-colored plastic.

Plastics with better light resistance can be formulated according to their original colors. While plastics with poor light resistance must be considered when coloring formulations are considered to change color in order to obtain good results.

2. Staining factor

At present, plastics dyeing is generally carried out by two methods: color masterbatch or dyeing granulation (toner). The colorant is the most important factor for the color difference of plastics parts. The color quality of plastic parts directly depends on the quality of the base color of the dye. Different thermal stability, dispersibility and covering ability will cause large deviations in the color of plastic parts.

3. Processing technology

In the process of dyeing plastics parts, the temperature, back pressure of injection molding, equipment technology and environmental cleanliness will all cause large deviations in the color of plastics parts. Therefore, it is necessary to maintain the consistency of the plastics injection molding equipment and the environment. A stable injection molding process is a key step to ensure that the color difference of the plastics parts is within the qualified range.

II. Portable colorimeter help plastic parts color difference control

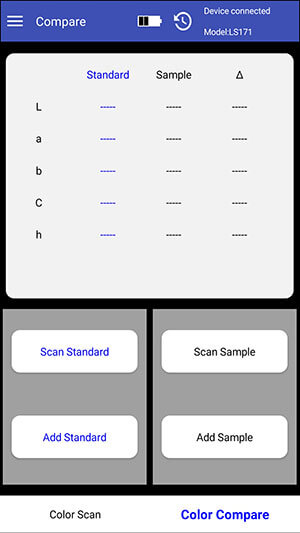

Does color affect plastics strngth? The answer is “Yes" . The plastics color is affected by many factors such as lquid versus solid,color versus appearance and acceptance criteria. How to make to plastics parts color meet the standard? We recommend a colorimeter. Color difference control of plastic parts can be achieved by using Linshang portable colorimeter. With the continuous development of science and technology, various types of color difference measurement tools are now increasingly developed, which can effectively help companies achieve color difference management and control. The colorimeter can accurately assess the color difference between two products. It automatically compares the color difference between the sample and the tested product. Then outputs the three sets of CIE-LAB data and the five values of ΔL, Δa, Δb,C,H.

III. Colorimeter principle

One of the core technologies of the colorimeter is the integrating sphere. The design incorporating the principle of the integrating sphere makes the measurement of the colorimeter more accurate and reliable and is more suitable for market color measurement needs. The integrating sphere is equivalent to an optical diffuser. In optics, the main function of the integrating sphere system is to measure the irradiance, chromaticity, luminosity and other light and color parameters of the light source, mainly for the luminous flux, illuminance, color temperature, chromaticity coordinates and luminous efficiency of the light source. Most of the famous colorimeters on the market are handheld or portable colorimeters, so the relative size of the integrating sphere is relatively small. However, the requirements for integrating spheres used in precision instruments such as colorimeters are indeed very strict, requiring very high uniformity and stability. The integrating sphere is a hollow sphere coated with a diffuse reflection coating on the inside. The outside is generally a metal structure with several small holes. There are standard light sources, auxiliary light sources, light interfaces, etc. inside the integrating sphere, and an external power supply and processor for the colorimeter. Linshang portable colorimeter LS171 uses the integrating sphere principle. It is widely used in car paint spraying, test paper printing, leather fabrics, plastic metal, textile and clothing, hardware, furniture industry, plastics, rubber and other fields.