Can Paint Gloss Meter Detect Metal Coating Gloss

1. What is the surface gloss of the metal coating?

The gloss of the coating surface refers to the ratio or intensity of the reflected light under the action of a certain illuminance and a certain angle of incident light. The greater the ratio or intensity of the reflected light, the higher the coating gloss. The plating layer gloss is an important performance indicator, which will greatly affect the appearance of the product. You can use Linshang paint gloss meter to test its specific gloss value. The coating layer with high gloss, full and bright color, gives people a magnificent feeling and caters to people's psychological needs, so it is generally welcomed. Coatings with poor glossiness appear dull in color, giving an old, depressed feeling and reducing the impression of the product in the minds of customers.

The so-called gloss refers to the numerical value indicating the degree to which the coating surface is close to the specular surface. There are various evaluation methods, including visual evaluation method, sample comparison method and paint gloss meter measurement method.

2. Factors affecting the gloss of the coating surface

The purpose of electroplating is to apply a metal coating on the substrate to change the surface properties or size of the substrate. Electroplating can enhance the corrosion resistance of the metal (mostly, the coating metal uses corrosion-resistant metals), increase hardness, prevent wear, and improve conductivity. The gloss value can be directly detected using a paint gloss meter. Factors affecting the surface gloss of the plating layer:

It is the surface gloss of the base material of the parts, which can be directly measured with a paint gloss meter.

Is the composition of the plating solution, including the concentration, additives, and various impurities are within the scope of the process.

It is the bath temperature.

3. The paint gloss meter detects the specific gloss value of the coating

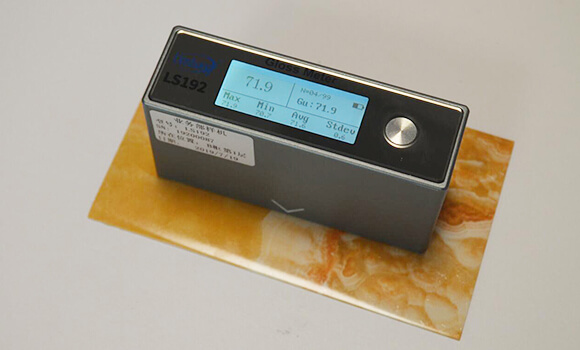

In the decorative coating, the main performance is to make the coating have perfect brightness. Taking chrome plating as an example, in the early stage of chrome plating, people used polishing to achieve the purpose of brightness. Nowadays, people use bright transition fluids of various metals to meet the requirements of high brightness. However, it is difficult to develop a bright chromium plating solution. The existing protective-decorative chrome plating process focuses on the study of the intermediate plating layer. The intermediate plating layer is used to achieve a full-bright effect. You can use Linshang LS192 paint gloss meter to easily and quickly detect the surface gloss value.

4. Linshang paint gloss meter

Linshang LS192 portable paint gloss meter can be used to test the surface gloss of paints, coatings, inks, plastics, paper, tiles, ceramics, stone, metal and electroplated products. It is a 60-degree angle paint gloss with a range of up to 1000GU. The test data is comparable to the German BYK gloss tester.

The clever design of the host and base of the LS192 paint gloss meter well protects the standard board from contamination. The instrument does not need to be calibrated every time it is turned on. For the self-diagnosis function of the specific standard board fouling of the paint gloss meter. When the standard value of the standard board is not within the qualified range, the paint gloss meter will automatically prompt you to clean the standard board. And with real-time temperature compensation function, no matter what temperature environment, it can ensure the stability of the instrument, so that the measurement results are stable and reliable.