Plastic Gloss Detection Standard and Method for Improing Gloss

The main component of plastic is resin, which is a polymer material mixed with various additives. Due to its light weight, stable chemical properties, easy molding and coloring and low processing costs. Therefore, plastics are widely used in various industries such as agriculture and industry. With the needs of the living industry, the application of digital gloss meters is becoming more and more widespread.

1. Plastic gloss test standards

In order to accurately evaluate the gloss of plastic mirror surface, it can be tested in accordance with the national standard GB / T 8807-1988 "Test Method for Plastic Mirror Gloss". This standard specifies three methods for measuring the specular gloss of plastics with 20 °, 45 ° and 60 ° angles, which are applicable to the measurement of plastic specular gloss. The 20 ° angle is mainly used for high-gloss plastic, the 45 ° angle is mainly used for low-gloss plastic. The 60 ° angle is mainly used for medium-gloss plastic. For the comparison of specular gloss, it is only applicable to the same type of plastic using the same method.

(1) Sample and preparation requirements

The surface of the specimen shall be smooth and free of defects such as dirt and scratches. Specimens shall be cut at different locations, the size of which shall be 100mm * 100mm. Each set of specimens shall be no less than three in the test.

(2) Standard board requirements

First-level work standard board: Use highly polished flat black glass plate. For a 20 ° angle and a 60 ° angle, a black glass plate with a refractive index of 1.567 is used. The gloss value is specified as 100 GU; for a 45 ° angle, a black glass plate with a refractive index of 1.540 is used, the gloss value is specified as 55.9 GU.

Class II working standard board: Use hard, flat, uniform surface ceramics, etc., which meets the requirements for correction of mirror gloss meter.

The standard board must be kept clean and must not damage its surface. When in use, hold the edges and never touch the surface. When cleaning, do not wipe with a towel, a stiff brush or paper. The surface of the lens should be cleaned with a cleaning solution for optical lenses.

(3) Test steps

The digital gloss meter must be calibrated during the test. First, the primary working standard board is calibrated and then the mirror gloss of the secondary working standard board is checked. If the measurement reading of the secondary working standard board exceeds its nominal value by one gloss unit, then the digital gloss meter must be adjusted by the manufacturer before it can be used. After the digital gloss meter is calibrated, you can use the digital gloss meter to directly detect it.

It is worth mentioning that many glossmeters on the market now support the automatic calibration function. When the instrument is turned on, the calibration can be automatically performed. After the startup, the measurement interface will be directly entered. After the user selects the measurement mode and measurement angle, the surface of the sample to be tested can be detected. When measuring, press the gloss meter's measuring aperture close to the tested plastic surface to avoid the interference of external light. Press the measurement button and the gloss meter's screen will display the gloss measurement value of the measurement area.

2. How to improve plastic surface gloss?

If the lack of surface gloss of a product is detected by a digital gloss meter, how should we deal with it? The brightening method of plastic is to improve the gloss or plastic products surface finish. In addition to the selection of raw materials, the method also includes adding extenders, morphological control brightening methods, surface coating brightening methods and so on.

(1) Raw material selection

The plastic raw materials themselves have different gloss characteristics. Selecting high-gloss raw materials will increase the surface gloss of the plastic products produced accordingly.

(2) Additive selection

Different additives such as lubricants and stabilizers can also affect the surface gloss of plastic parts.

(3) Brighten surface coating

The basic principle of plastic brightener is to form a thin film on the surface of the product, which greatly improves the smoothness and gloss of the product surface.

3. Plastic gloss test

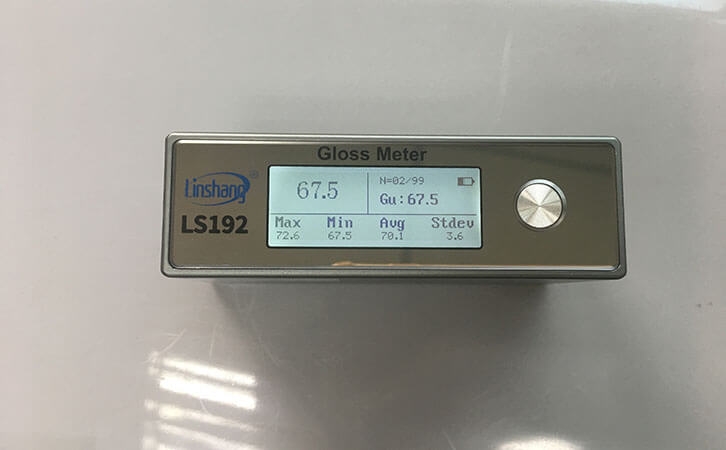

Testing plastic gloss, we generally uses a digital gloss meter to check the gloss of the plastic surface to determine the quality of the product. A digital gloss meter can be used not only to measure plastic, but also to detect materials such as marble, ink, paint, and hardware. For example, Linshang LS192 digital gloss meter can be used to measure the gloss of plastic surfaces. The measuring angle of the instrument is 60 degrees and the instrument has the following characteristics:

●Real-time display of measurement data, no need to press the button for instant measurement.

●The instrument has powerful intelligent statistical functions that can measure standard deviation, maximum, minimum, average values and number of measurements.

●The instrument has the function of ambient temperature compensation, allowing long-term calibration and stable measurement values.

●The instrument is equipped with special operation software, which supports USB transmission. It can be operated online with the computer and complete the test report.

●The instrument has low energy consumption, small size, good texture and it is easy to carry.