Why should We Use Exposure Machine UV Integrator?

The exposure machine UV integrator is mainly used for detecting the UV light irradiation intensity and UV energy of the UV light source in the exposure machine. The main function of the exposure machine is to cause chemical changes of the sensitizer in the photoresist by ultraviolet irradiation. Through the detection of the exposure machine UV integrator, we can control the exposure time and the UV light irradiation intensity of the UV lamp to achieve the proper photoresist exposure effect.

I. The working principle of exposure machine

The exposure machine is mainly used in the lithography process in the semiconductor device manufacturing process. Photolithography mainly uses the exposure and development to characterize the geometric structure on the photoresist layer and then transfers the pattern on the photomask to the substrate by an etching process.

UV LED light source can be divided into point light source and area light source. Area light source composed of many LED lamp beads.These LED light sources are arranged side by side. The exposure machine can selectively illuminate the photoresist through the light emitted by these UV LED light sources with specific wavelengths. The photochemical reaction takes place and the area after the chemical reaction can be dissolved in a specific developer. The transfer of the mask pattern can be performed by using different sensitivities of the photosensitive and non-photosensitive photoresists to the alkaline developer solvent.

II. Consequences of underexposure or overexposure

An excellent dry film resist image can be obtained by properly controlling the exposure time using the exposure machine UV light integrator.

1. Effects when the exposure is insufficient

When the exposure is insufficient, due to the incomplete chemical reaction in the sensitizer, during the development process, the film will melt and soften. The lines are not clear enough, the color is dim and even degumming. During the pre-plating treatment or electroplating process, the film may be warped, plated, or even peeled off.

2. Effects when the exposure is excessive

When the exposure is excessive, it may cause that the film is brittle, leaving residual glue and the like. Therefore, the exposure time and illumination intensity of the exposure machine need to be strictly monitored.

III. UV integrator for UV LEDs and high pressure mercury lamp

The Linshang exposure machine UV integrator is a professional device for detecting the UV energy of UV LED light sources in exposure machines. The instrument can record the UV light irradiation intensity and UV energy value of the received ultraviolet light, place the instrument at the position of the photoresist to be exposed. The UV integrator can record the UV light irradiation intensity of the ultraviolet light received by the photoresist in the exposure machine and the accumulated UV energy in real time. The successful exposure is achieved by controlling the UV light irradiation intensity and exposure time of the UV LED light source in the exposure machine. Different light sources should be detected by different UV integrators. Linshang Technology has developed four UV integrators for UV LED light sources and high pressure mercury lamps respectively.

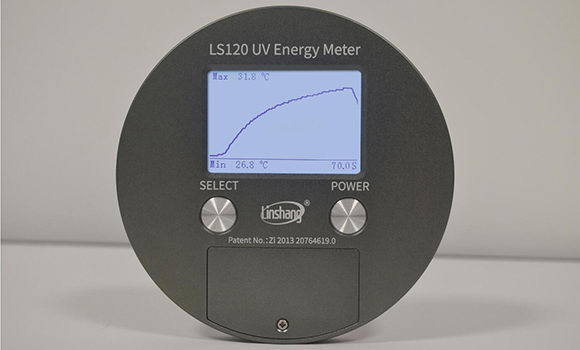

● Spectral response range: 315nm-400nm, λp = 365nm

● UV power (intensity) measuring range: 0 - 2000 mW/cm²

● Measure energy, power and temperature, provide PC software to export the data

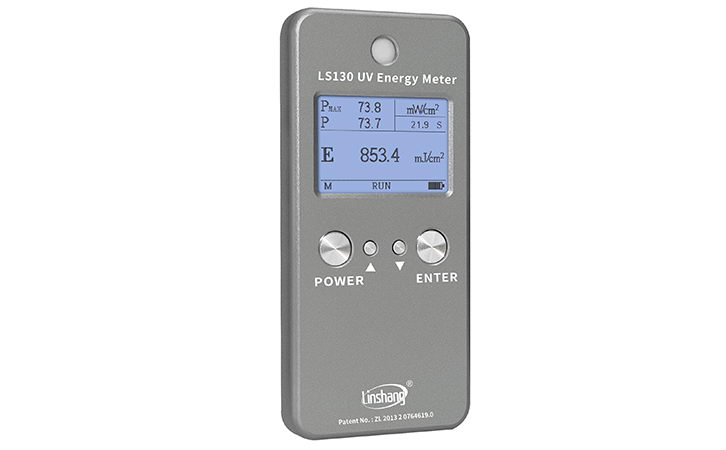

● Spectral response range: 315nm-400nm, λp = 365nm

● UV power (intensity) measuring range: 0-2000 mW/cm²

● Measure UV energy and power (intensity), provide PC software to export the data

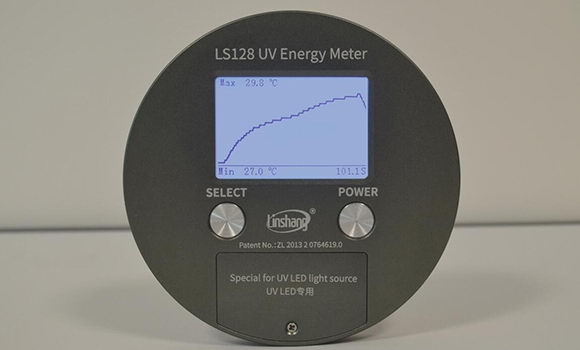

● Response range: 340-420nm, calibrated at 395nm LED

● UV intensity measuring range: 0 - 40000 mW/cm²

● Measure energy, power and temperature, provide PC software to export the data

● Response range: 340-420nm, calibrated at 395nm LED

● UV intensity measuring range: 0 - 40000 mW/cm²

● Measure UV energy and power (intensity), provide PC software to export the data