Window Film Transmission Meter Selection and FAQ

I. Linshang Window Film Transmission Meter Selection Table and Price List

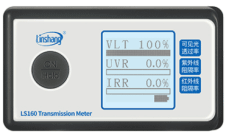

1. Portable Three-band Window Film Transmission Meter

| model | Appearance | Features |

|---|---|---|

| LS160 |

|

Similarities: 1. Pocket-sized, compact, can be held in one hand. 2. 0.8mm notch, only suitable for thin films. 3. Dimensions: 93mm × 25mm × 52mm 4. 365nm UV blocking rate, 530nm transmittance. Differences: 1. LS160 measures 940nm infrared blocking rate. 2. LS160A measures 1400nm infrared blocking rate. 3. LS160 is suitable for general heat-absorbing films. 4. LS160A is suitable for all films. |

| LS160A |

|

|

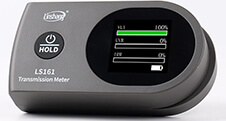

| LS161 |

|

Similarities: 1. Pocket-sized, compact, can be held in one hand. 2. 0.8mm notch, can only measure thin films. 3. Dimensions: 101mm × 52mm × 25.5mm 4. Color display screen. 5. 365nm UV blocking rate, 380-760nm transmittance. Differences: 1. LS161 measures 940nm infrared blocking rate. 2. LS161A measures 1400nm infrared blocking rate. 3. LS161H can measure 940nm/1400nm/full infrared blocking rate, SHGC, TSER value. 4. LS161 is suitable for general heat-absorbing films. 5. LS161A/LS161H are suitable for all films. |

| LS161A |

|

|

| LS161H |

|

|

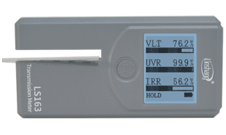

| LS163A |

|

1. 6mm notch, suitable for measuring solar films, laminated glass, and automotive side windows. 2. Dimensions: 146mm × 73mm × 24mm 3. Measures 365nm UV rejection rate, 380-760nm transmittance, 940nm/1400nm infrared rejection rate, total infrared rejection rate, SHGC, and TSER values. 4. Rotatable screen allows for flexible combination of displayed parameters. |

| LS163 |

|

1. 6mm notch, suitable for measuring ordinary heat-absorbing films, laminated glass, and automotive side windows. 2. Dimensions: 146mm × 73mm × 24mm 3. 365nm UV blocking rate, 380-760nm transmittance, 940nm infrared blocking rate. 4. Rotatable screen, three display interfaces available. |

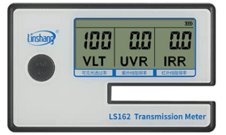

| LS162 |

|

Similarities: 1. 8mm notch, suitable for measuring films, laminated glass, and automotive side windows. 2. Dimensions: 120mm × 25mm × 75mm 3. 365nm UV blocking rate, 380-760nm transmittance. Differences: 1. LS162 measures 940nm infrared blocking rate. 2. LS162A measures 1400nm infrared blocking rate. 3. LS162 is suitable for general heat-absorbing films (glass). 4. LS162A is suitable for all films (glass). |

| LS162A |

|

2. Desktop and split window film meter

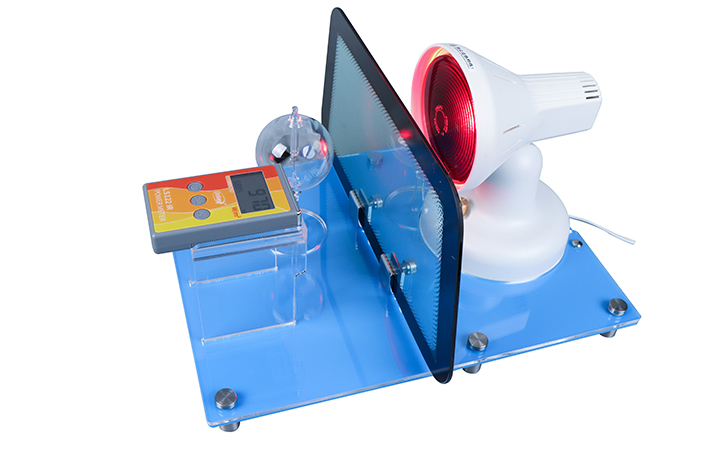

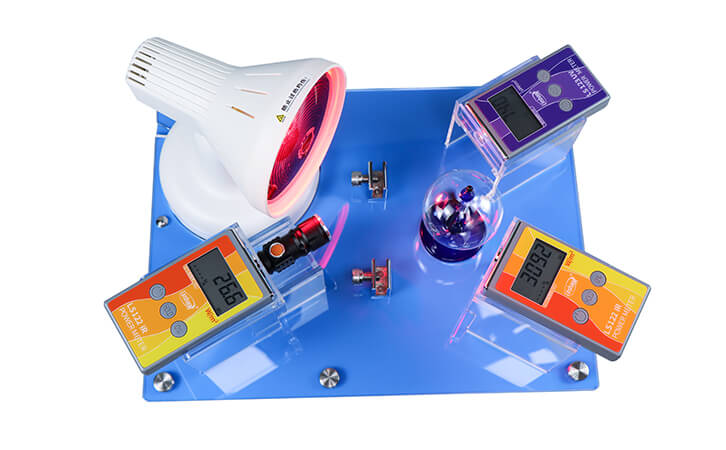

3. Demonstration Window Film Transmission Meter

II. Product Details of Linshang Window Film Transmission Meter

● Ultra-small size design

● Ultraviolet light: 365nm, visible light: 530nm

● Infrared: 940nm (LS160); 1400nm (LS160A)

● Suitable for LS161 general heat-absorbing films; suitable for all LS161A films.

● UV light: 365nm, Visible light: 380-760nm (compliant with CIE photopic function)

● Infrared light: 940nm (LS161), 1400nm (LS161A)

● UV: 365nm, Visible: 380-760nm (compliant with CIE photometric function)

● LS161H can measure 940nm/1400nm/full infrared blocking rate, SHGC, TSER value

● Suitable for testing films, laminated glass and automobile side glass

● Ultraviolet light: 365nm, visible light: 380-760nm (in line with CIE photopic luminosity function)

● Infrared: 940nm (LS162); 1400nm (LS162A)

● Suitable for testing films, laminated glass and automobile side glass

● Visible light transmittance / full transmittance / transmittance + rejection rate, three display modes can be switched

● Ultraviolet light: 365nm, visible light: 380-760nm (in line with CIE photopic luminosity function)

● Infrared: 940nm

● Suitable for testing films, laminated glass and automobile side glass

● Multiple display interfaces are available for switching

● Measurable UV 365nm, visible light 380-760nm, 940nm/1400nm/full infrared blocking rate, SHGC, TSER value

● Suitable for testing films, laminated glass and automobile side glass

● Adopt large-screen LCD, support 4 AA batteries and 5V power supply

● Ultraviolet: 365nm, visible light: 380-760nm (in line with CIE photopic luminosity function), infrared: 940nm

● Suitable for measuring all kinds of installed glass, such as automobile front shield, curtain wall glass, etc.

● Built-in rechargeable lithium battery and magnet for easy going out testing

● Ultraviolet light: 365nm, visible light: 550nm

● Infrared: 940nm (LS110A); 1400nm (LS110H)

● It is suitable for testing the heat insulation, UV rejection and light transmission performance of various films and glass in the store.

● Ultraviolet light: 365nm, visible light: 550nm

● Infrared: 940nm, 1400nm and full band can be switched

● Test SHGC solar total transmittance (solar heat gain coefficient)

● Using 150W genuine Philips infrared light source and imported temperature probe

● LS300 can display the real-time temperature in the space below the instrument and the temperature difference.

● LS301 can display real-time temperature in the space below the instrument and infrared rejection rate of glass

● LS123 spectral response range: 260-400nm

● LS122 is used to test the real-time infrared radiation intensity and infrared rejction rate of materials

● LS123 is used to test the real-time infrared radiation intensity and UV rejection rate of materials

● Suitable for demonstration of insulation glass with better reflective insulation performance

● Note: Only test the intensity of infrared radiation reflected by the heat-insulating material, not the reflectance of the material

III. FAQ about Linshang Window Film Transmission Meter

-

1. What is the difference between 940nm and 1400nm instruments?

The two bands of 940nm and 1400nm are relatively representative bands. Most of the absorption films (heat-absorbing films) have better infrared blocking effect at 940nm, while the magnetron sputtering reflection film has better blocking effect at 1400nm such as metal film and ceramic nano film. Please choose the right instrument for your own film category.

-

2. What is the difference between a metal film and an endothermic film?

The metal film is produced by a magnetron sputtering process. A large amount of metal elements are added and the has a good reflection ability to the infrared film. It is insulated by the principle of reflecting infrared rays.

The absorption film is added with an infrared absorber during production and the infrared is absorbed by the film. It is insulated by the absorption principle and secondary heat radiation will be generated after the heat absorption is saturated.

-

3. Can 940nm instrument measure metal film? Can the 1400nm instrument measure endothermic films? When the same film is tested by both 940nm and 1400nm, what is the difference in infrared rejection rate?

Each film tested by both 940nm and 1400nm instruments will have infrared blocking rate data. Due to different production processes, the thermal insulation data of some films at 940nm will be larger than the thermal insulation data of 1400nm. Some films will have larger thermal insulation data at 1400nm.

E.g: Vickers V70 has an official infrared rejection rate of 98%. The measurement data tested by 1400nm instrument is about 98%, while the measurement data tested by 940nm instrument is only about 88%.

The 3M Jingrui 70 has an official infrared rejection rate of 98%. The measurement data tested by 940nm instrument is about 99%, while the measurement data tested by 1400nm instrument is only about 87%.

There are too many types of films and the data differences between 940nm and 1400nm are also very different. Some films may not differ much and some films differ by 30-40%, so we can't tell you the exact value.

-

4. Why are 1400nm instruments so much more expensive than 940nm instruments?

It's all about the cost of raw materials. The cost of a 1400nm light source and receiver is much higher.

-

5. Can the window film transmission meter measure the insulation rate?

Our instrument measures the infrared rejection rate. The higher the infrared rejection rate, the higher the thermal insulation rate. Because visible light also has a small amount of heat, in the strict sense, the heat insulation rate needs to integrate visible light, infrared and ultraviolet heat insulation data. Ultraviolet heat is very small and visible light is beneficial. Therefore, infrared is the main source of heat, so the infrared rejection rate is basically equivalent to the thermal insulation rate.

-

6. What is the difference between LS300 and LS301?

The LS300 measures the real-time temperature (degrees Celsius) and the temperature difference. The LS301 has an additional function to measure the infrared rejection rate of 940nm than the LS300. At the same time, the LS301 also measures the real-time temperature value.

-

7. What is the difference between the new and old LS101?

The parameters of the new and old models are basically the same, both of which can measure three parameters of heat insulation, UV rejection and light transmission.

The old model can only be used when plugged in. It is a digital tube display. The new model is an LCD display. It uses 4 AA batteries and has a USB interface on the instrument. It can be directly powered by a power bank or 5V charging head.

The light source of the old LS101 is a point light source, which is only suitable for films and thin glass; the new LS101 uses a parallel light path design and thick glass can also be tested.

-

8.Are you a manufacturer or trade company?

We are factory , we have engineers for researching & designing and workers for produce and operate etc, we could support you one-stop products and service.

-

9.Do you offer OEM and ODM service?

Yes. We can supply OEM and make customized design for any specific application.

- Choosing the Right Window Tinting Film

- Window Tint Meter | Pros and Selection Methods of Architectural Membrane

- Advantages of LS110H and LS110A Split Transmission Meter

- Best Choice:LS182 Solar Film Transmission Meter

- Solar Power Lightens Up with Thin-Film Technology

- What is the Solar Heat Gain Coefficient Ratings (SHGC)